Service, Lubrication – Carrier 50DQ User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

t

SERVICE

Head Pressure Control

shuts off one outdoor air

fan at 60 ± 3 F and restarts fan at 70 ± 3 F.

Sensing device is an ambient air temperature

sensing thermostat attached to the unit compressor

compartment side panel.

Refrigerant Coils

remove dirt and debris from

indoor and outdoor coils as required.

INDOOR AIR COILS may be cleaned with a stiff

brush, vacuum cleaner or compressed air.

Access to the fan side of the indoor coil on unit

can be obtained by removing the complete indoor

air fan assembly, less motor, from unit as one

piece. To remove indoor air fan assembly;

1. Turn unit power off.

2. Loosen fan motor and remove belt.

3. Remove four screws on each end of assembly.

Gain access to journal end of air fan section

thru lower right access panel inside compressor

compartment.

4. Lift and slide complete fan assembly from unit.

5.

Reassembly is a reversal of the preceding

procedure.

OUTDOOR AIR COILS may be cleaned using a

stiff brush, vacuum or low-pressure water, steam or

air. Outdoor air fan motors are dripproof, not

waterproof.

Filters

— Clean or replace filters as required. Refer

to Table 1 for type of filters used. Filter tracks

have spacers which, when removed, permit the use

of 2-in. filters. To remove filters, remove filter

access cover on either side of unit. Slide out filters.

TO CLEAN FILTERS ^ Flush cleanable filters

with hot water or steam or soak in mild solution of

soap or detergent and water. Allow filters to dry.

Coat filters with a dust adhesive. Refer to filter

manufacturer’s instructions as required for all

other types of filters. Do not operate unit without

air filters.

Condensate Drain

— Clean annually at start of

cooling season. In winter keep drain and trap dry

or protect against freezing.

Indoor Air Fan Adjustment

— Speed (Table 1) and

alignment is factory set but is adjusted as follows:

TO CHANGE FAN SPEED

1. Loosen fan belt by loosening fan motor mount

ing plate bolts.

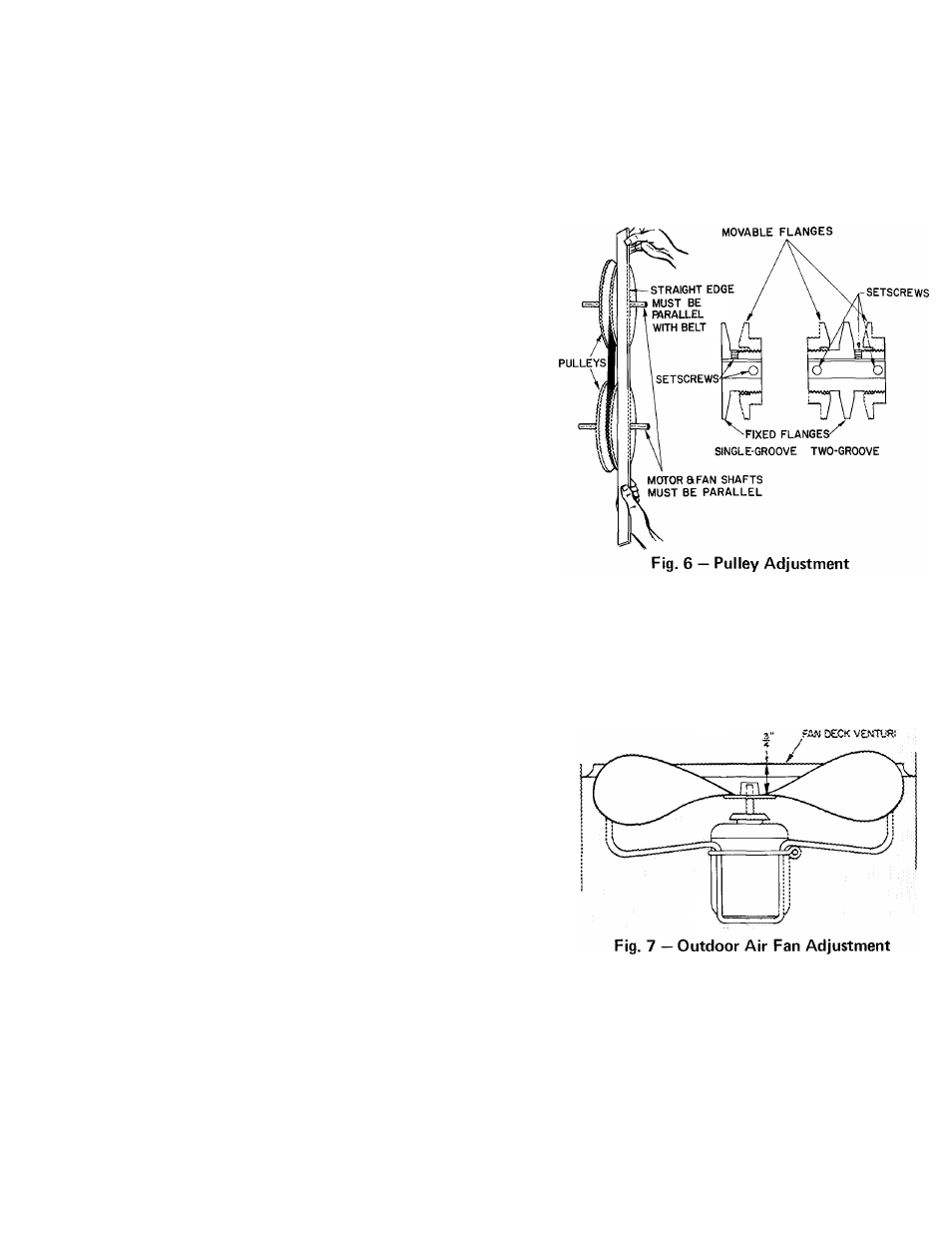

2. Loosen pulley movable flange setscrews (Fig. 6).

3. Screw movable flange toward fixed flange to

increase speed and away from fixed flange to

decrease speed.

Increasing fan speed increases load on motor.

Do not exceed maximum fan speeds (Table 2).

4. Tighten movable flange setscrews at nearest flat

surface of pulley hub.

TO ALIGN FAN AND MOTOR PULLEYS -

Loosen fan pulley setscrews and slide fan pulley

along fan shaft. Make angular alignment by loosen

ing motor from mounting plate. Check alignment

with a straight edge (Fig. 6).

TO ADJUST BELT TENSION

1

.

2

.

3.

Loosen motor mounting plate pivot bolts.

Pull motor mounting plate up or down as

required to attain approximately 3/4-in. de

flection with one finger.

Tighten lock bolt and nut (if fitted) under

motor mounting plate to secure in fixed

position.

Outdoor Air Fan Adjustment (Fig. 7)

— Turn unit

power off. Remove fan guard and loosen fan hub

setscrews. Adjust fan height using a straight edge

laid across venturi. Tighten setscrews and cover

hub recess with rubber boot to prevent hub from

rusting to motor shaft.

Lubrication

COMPRESSOR should operate with crankcase

warm to the touch. Run unit 15 to 20 minutes or

until cooling system has stabilized. Sight glass

should be 1/2 full of oil (See Compressor Service

Instruction Manual.)

ALL FAN MOTORS AND BEARINGS are factory

lubricated and sealed. Bearings are designed to be

replaced rather than relubricated. Gain access to

journal end of evaporator air fan section thru lower

right

hand

access

panel

inside

compressor

compartment.