Carrier 50AH024-060 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

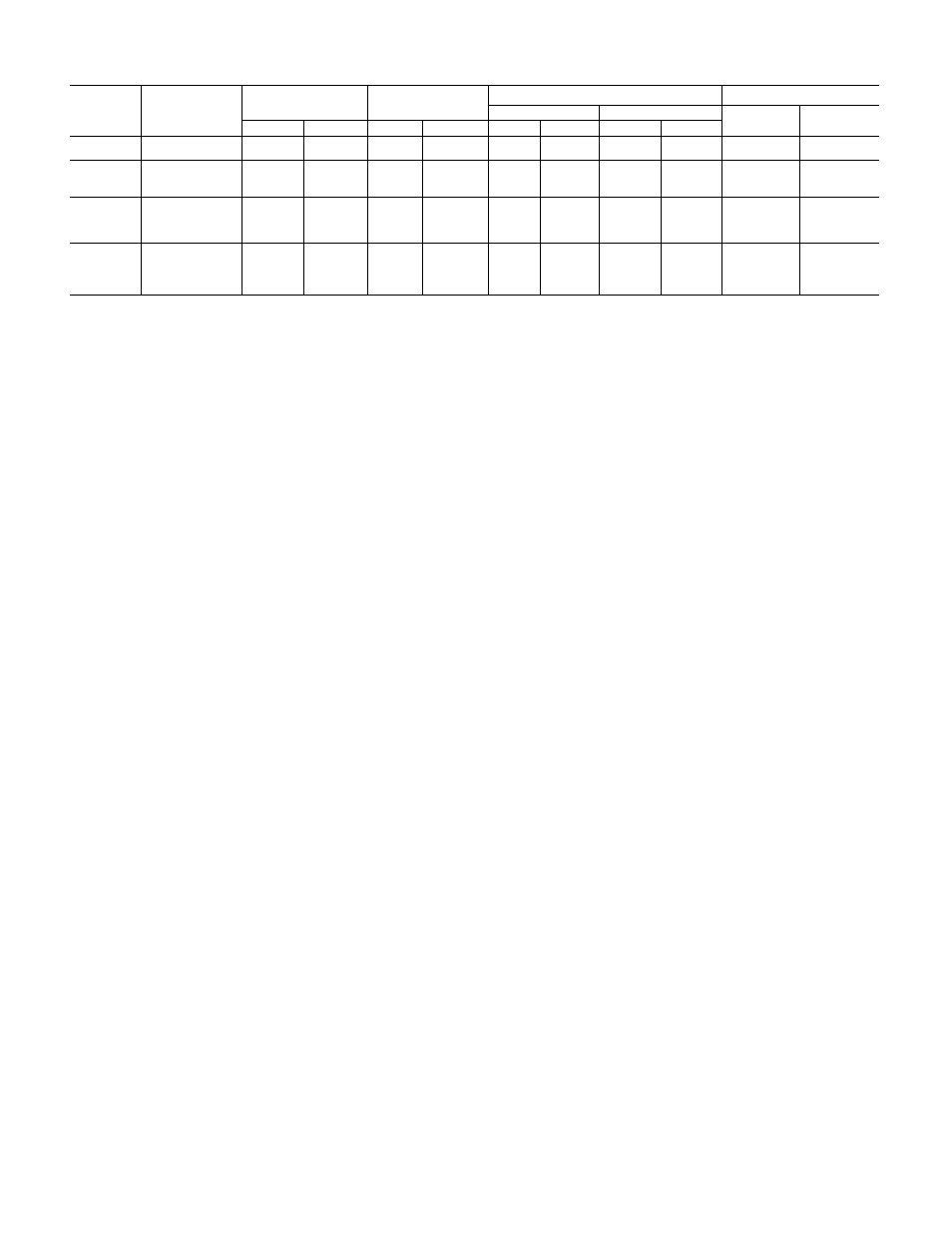

Table 2 — Electrical Data

UNIT

50AH

FAN MOTORS

POWER SUPPLY

V-PH-HZ

Indoor

Outdoor

Min Ckt

MOCP

Min

Max

RLA

LRA

Hp

FLA

Hp

FLA

Amps

Amps

024

230-1-60

207

254

126

64 0

33

1 32

.31

NEC

34

20 8

25

230-1-60

207

254

17 5

86 7

50

3 20

75

6 06

31 7

40

036

208/230-3-60

187

254

121

65 1

50

3 20

1 0

3 93

22 0

30

460-3-60

414

508

5.6

32.8

.50

1.50

1.0

1.97

11.0

15*

230-1-60

207

254

22 5

98 0

75

40

1 0

8 35

40 5

60

048

208/230-3-60

187

254

160

80

0

75

40

1 0

3 93

27 9

35

460-3-60

414

508

72

35 0

75

2 15

1.0

1 97

132

15*

575-3-60

518

632

6,8

27.0

.75

1.40

1.0

1.45

11.4

15

230-1-60

207

254

32 5

130 0

75

4.0

1 5

9 50

55 0

70*

060

208/230-3-60

187

254

21 7

98 0

75

40

1 5

4 82

36

6

45

460-3-60

414

508

108

49 0

75

2 15

1 5

2 41

185

25*

575-3-60

518

632

83

41 0

75

1 40

1 5

1 90

139

20

FLA — Full Load Amps

Hp

— Horsepower

LRA — Looked Rotor Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

'Fuse oniy

Step 6 — Install Ductwork

— Use flexible duct

work to attach duct to unit and to help control trans

mission of vibrations to building structures. Attach

ductwork to the return and supply ends of both coils.

If unit is located with condenser close to outside of

building, install a field-supplied rain hood. Hood intake

dimensions should be same as eondenser return air

dimensions. In addition, install a triple layer bird screen

over rain hood intake to eliminate possibility of insects,

birds, water or debris from entering unit.

Step 7 — Make Electrical Connections

— Con

nect power wiring to junction box located on unit side

near control box access panel. All wiring must comply

with National Electrical Code and all local code

requirements.

Operating voltage to compressor must be within volt

age range as indicated on unit nameplate. On 3-phase

units, voltages between phases must be balanced within

2% and current must be balanced within 10%. Contact

local power company for correction of improper voltage

or phase imbalance. Unit failure as a result of operation

on improper line voltage or excessive phase imbalance

constitutes abuse and may cause damage to electrical

components. Such operation would invalidate any appli

cable Carrier warranty.

Install a fused disconnect per NEC on the 5-ton (060)

230-1-60 unit. Refer to unit informative nameplate and

Table 2 for fuse sizes and wire amperages for all units.

NOTE: The following installation steps are for unsplit

systems. For split systems, 8 suspension rods are required.

Also refer to following Splitting Systems instructions:

Splitting Systems

— 50AH roomtop units may be

split into 2 sections if desired, with condensing section

mounted remotely either horizontally or vertically. If

sections are installed in same horizontal plane they may

be separated by up to 75 ft of tubing.

Condensing section must be located in same plane as

or above evaporator section to maintain the liquid refrig

erant seal at the expansion device. This permits expan

sion device to feed liquid refrigerant to evaporator coil

properly. To split sections (the following sequence of

steps may be adjusted depending on particular

application):

1. Disconnect all electrical power to unit.

2. Remove 4 bolts connecting the 2 sections.

3. Remove top panels from each section.

4. Bleed off the refrigerant through the Schrader valve

located in evaporator section.

5. Cut refrigerant piping in the evaporator section just

inside the partition between the 2 sections.

6. Unsweat the cut portions of the refrigerant piping in

evaporator section at the closest bell joint. The bell

joints are used to connect field-supplied refrigerant

piping to evaporator section. Cut and braze a length

of tubing to extend refrigerant piping outside the

evaporator section.

7. Cut outdoor fan motor wiring at the partitions

separating condenser and evaporator sections. Install

a junction box adjacent to D-shaped grommet on the

partition.

8. In the condenser section, install a junction box

adjacent to the D-shaped grommet.

9. Install evaporator and condensing sections in

desired locations referring to remainder of these

instructions.

10. Use appropriate length of no. 16 AWG (minimum),

4/ 64 insulated copper wire to reconnect cut outdoor

fan motor wires. Make connections in junction boxes

installed in earlier steps. Follow all applicable elec

trical codes.

11. Use sufficient length of refrigeration piping to

reconnect piping cut in previous step. Refer to

Carrier System Design Manual, Part 3, for additional

piping data.

After splitting sections, additional refrigerant must be

added to system to ensure proper refrigerant charge. The

amount of refrigerant to be added depends on length of

tubing added to system and operating temperatures of

system. Refer to Carrier System Design Manual,

Chapter 3.

Since standard roomtop unit has negligible line losses,

splitting the system can increase line loss and decrease

system capacity. Capacity reduction can be determined

referring to Carrier System Design Manual.

12. Recharge unit with R-22 following Charging Charts

(Fig. 4 - 7) in these instructions.

Field Control Wiring

— Install a Carrier-approved

accessory thermostat assembly according to installation

instructions provided by thermostat manufaeturer.

Locate thermostat assembly on a solid wall in the condi

tioned space to sense average room temperature.

Using thermostat cable or equivalent single leads of

No. 18 AWG colored wire, route cable or wire from

the subbase terminals, up and through connector on unit

side (below power lead junction box) and connect to low-

voltage terminal block inside the control box.

Thermostat Wire

— Use 18 gage for 0- to 50-ft long

wires and 16 gage for 51- to 75-ft wire lengths.