Step 6 — make txv adjustments, Start-up, Sequence of operation – Carrier 40RR024 User Manual

Page 5: Cooling

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

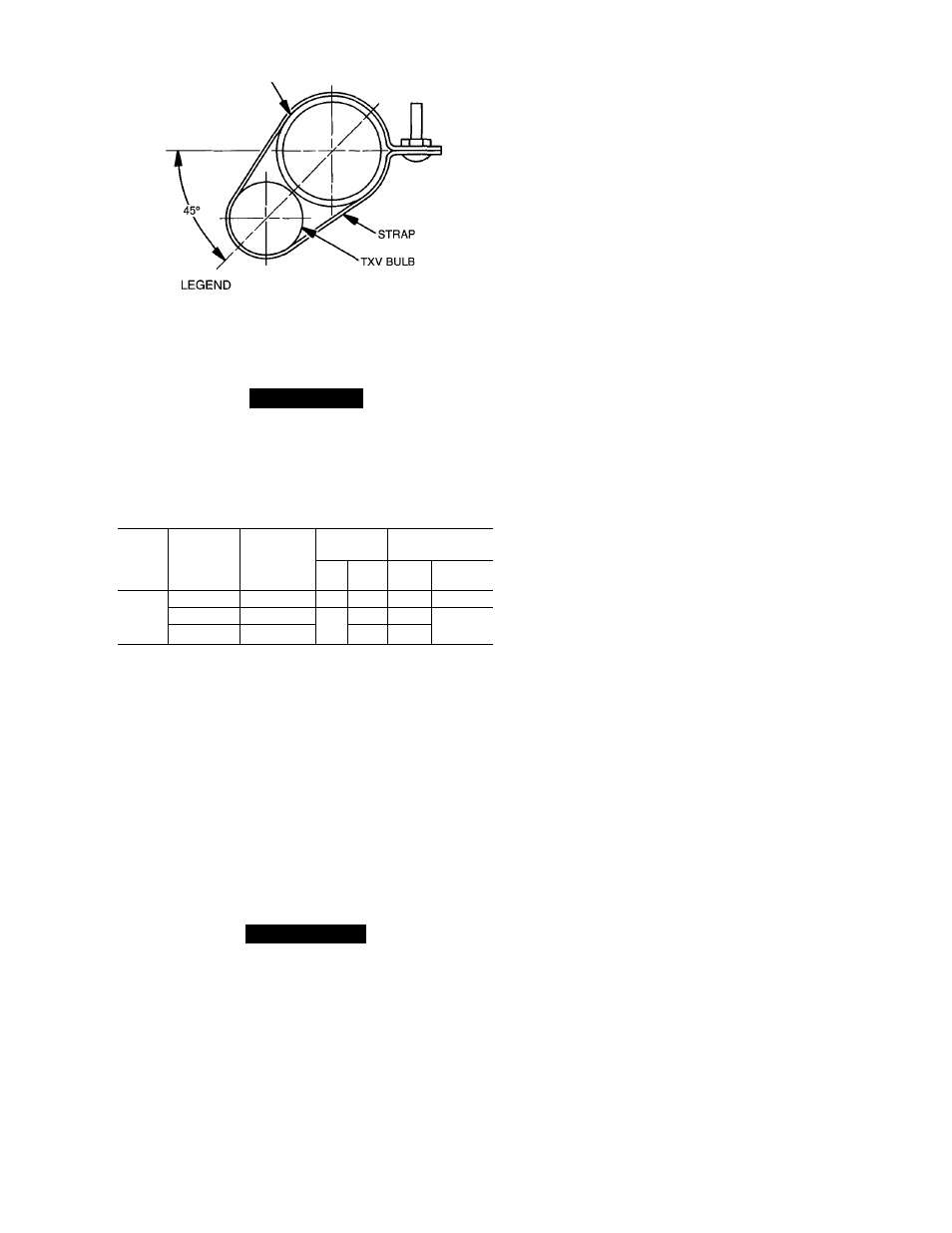

VAPOR LINE

TXV

— Thermostatic Expansion Valve

NOTE: The 8 o’clock position is shown above

Fig. 5 — TXV Feeler Bulb Locations

Step 6 — Make TXV Adjustments.

A

CAUTION

Wait 30 minutes between TXV adjustments to avoid

excessive superheat.

Make TXV adjustments on 40RR after installation of pip

ing package, verifying 10° F superheat.

Table 4 — Unit 40RR Electrical Data

UNIT

V*-PH-HZ

VOLTAGE

FAN

MOTOR

POWER

SUPPLY

LIMITS

Hp

FLA

MCA

MOCP

(Amps)

40RR

024

208-3-60

180-220

3

10.8

132

15

230-3-60

207-253

3

10.1

11.5

15

460-3-60t

416-528

5.0

58

LEGEND

FLA

— Full Load Amps

MCA

— Minimum Circuit Amps

MOCP

— Maximum Overcurrent Protection

‘Motors are designed for satisfactory operation at ± 10% of nominai

voitages shown. Voitages should not exceed the limits shown in the

“Voltage Limits” column.

fMotors must be field wired for 460 v in accordance with directions

on nameplate of motor.

NOTE: Fan motors are field supplied on unit 40RR024 (575 v) and

on 50-Hz units.

NOTE: Because this split system uses TXV’s in the heating

cycle, refrigerant charge can be adjusted during heating op

eration. When properly charged, the 40RR has approxi

mately 32° F of state point subcooling leaving circuits no.

1 and 2 from the indoor coil in the heating cycle. Use charg

ing chart on unit to complete charging (in cooling cycle

only).

NOTE: Use refrigerant R-22 only.

NOTE: Since the 38QP unit contains 2 refrigeration

circuits, both circuits must be charged separately.

To charge system:

1. Regulate valve at refrigerant (R-22) tank to maintain suc

tion pressure at 80 psig (551.6 kPa) while charging. Charge

with vapor only at suction side of unit.

NOTE: Do not depend on sight glass when charging unit;

use charging charts which are attached to the inside of each

compressor access panel.

2. Measure line temperature close to the liquid service valve,

and measure the pressure at the Schrader port on the liq

uid line service valve. Plot point on the charging chart.

If point is above the line, add charge. If point is below

the line, remove and reclaim charge until operating point

falls on the curve.

3. Allow system to operate for 20 minutes. Take tempera

ture and pressure reading at liquid service valve and check

values with the charging chart.

4. Record final installed system charge in ink on unit

nameplate.

CHECK OIL CHARGE — Allow system to run for approx

imately 20 minutes. Stop system and check compressor oil

level. Ten pints is the proper oil charge amount for a 6D

compressor. Add oil only if necessary to bring oil into view

in sight glass. Use only Carrier-approved compressor oil:

Petroleum Specialties .......................................... Cryol 150A

Texaco, Inc....................................................... Capella WE32

Witco Chemical Corp......................................... Sunisco 3GS

IMPORTANT: Do not reuse drained compressor oil

or oil that has been exposed to atmosphere. Proce

dures for adding oil are given in GTAC II, Module 5,

Charging, Recovery, Recycling, and Reclamation. To

remove oil: shut system off; isolate the compressor;

remove and reclaim the refrigerant in the compressor;

remove the compressor oil drain plug.

START-UP

Evacuate and Dehydrate

— Evacuate and dehy

drate entire refrigerant system as shown in General Train

ing Air Conditioning (GTAC) II, Module 4, System

Dehydration.

A WARNING

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant. Do not overcharge system

— this can cause compressor flooding. Never charge

liquid into the low-pressure side of the system. During

charging or removal of refrigerant, be sure indoor fan

system is operating.

Preliminary Charge

— Refer to GTAC II, Module 5,

Charging, Recovery, Recycling, and Reclamation for charg

ing methods and procedures. Charge system per Table 1 in

GTAC II by the liquid charging method and charging by

weight procedure.

Charge System (Cooling Only)

— Refer to GTAC

II, Module 5, Charging, Recovery, Recycling, and Recla

mation, and the following procedure.

SEQUENCE OF OPERATION

General

— The heat pump contains 2 independent re

frigeration circuits. Each circuit has its own set of indepen

dent controls, compressor, liquid line solenoid valve, re

versing valve, crankcase heater, TXV, and accumulator.

Circuit breakers provide overcurrent protection for com

pressors (in both heating and cooling modes). These re

quire manual reset at the 38QP unit control box. The oil

pressure safety and crankcase heater also require reset at

the outdoor unit.

Cooling

NOTE: When power is supplied to a system that is off,

crankcase heaters are energized. The reversing valve may

or may not be energized depending on mode of operation

(heating or cooling) when thermostat was previously

satisfied.

The following cooling operating sequence has both heat

pump circuits connected to a single, 2-circuit fan coil. The

system is controlled by a single 2-stage heat/2-stage cool

thermostat.