Accessories, Installation, Step 2 — size piping lines — employ one of the – Carrier 40RR024 User Manual

Page 2: Step 3 - check contents of piping package

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Accessories

PIPING PACKAGE — Contains check valves, thermo

static expansion valves (TXV’s), receiver, filter driers, and

tubing to connect the indoor coils for heat pump service.

THERMOSTAT HH07AT172 (HH07AT162 For Use on

Celsius Scale) — Used with subbase HH93AZ174, is a 2-stage

cool/2-stage heat thermostat with automatic changeover and

a lockout light. There is no provision for emergency heat.

THERMOSTAT HH07AT172 (HH07AT162 For Use on

Celsius Scale) — Used with subbase HH93AZ177, is a 2-stage

cool/2-stage heat thermostat. This combination has all the

features of HH07AT172 (HH07AT162)/HH93AZ174 plus

a provision for emergency heat.

SEQUENCER PACKAGE — Can be used with this system

when unloaders are added to the compressor(s). (Unloading

can be applied in the cooling cycle only. Unloading can

never be applied in the heating cycle.) The sequencer has

4-stage cooling capability.

ELECTRIC HEATERS — May be used with the 40RR in

door unit (see Table 1). Use a maximum of four 20-kW

(at 240 v) or 21.8-kW (at 480 v) electric heater assemblies.

ELECTRIC HEATER CONTROL PACKAGE 40RT900081

— Provides control for up to 3 stages of electric heat when

used with outdoor-air thermostat(s). Package must be used

whenever 40RT electric heaters are utilized. If a fourth

stage of electric heat is used, an additional field-supplied

heater control relay is necessary. This relay must have a

24-V coil with 230-v contacts. Outdoor thermostats

(part no. HH22QA040) are recommended for staging elec

tric heaters.

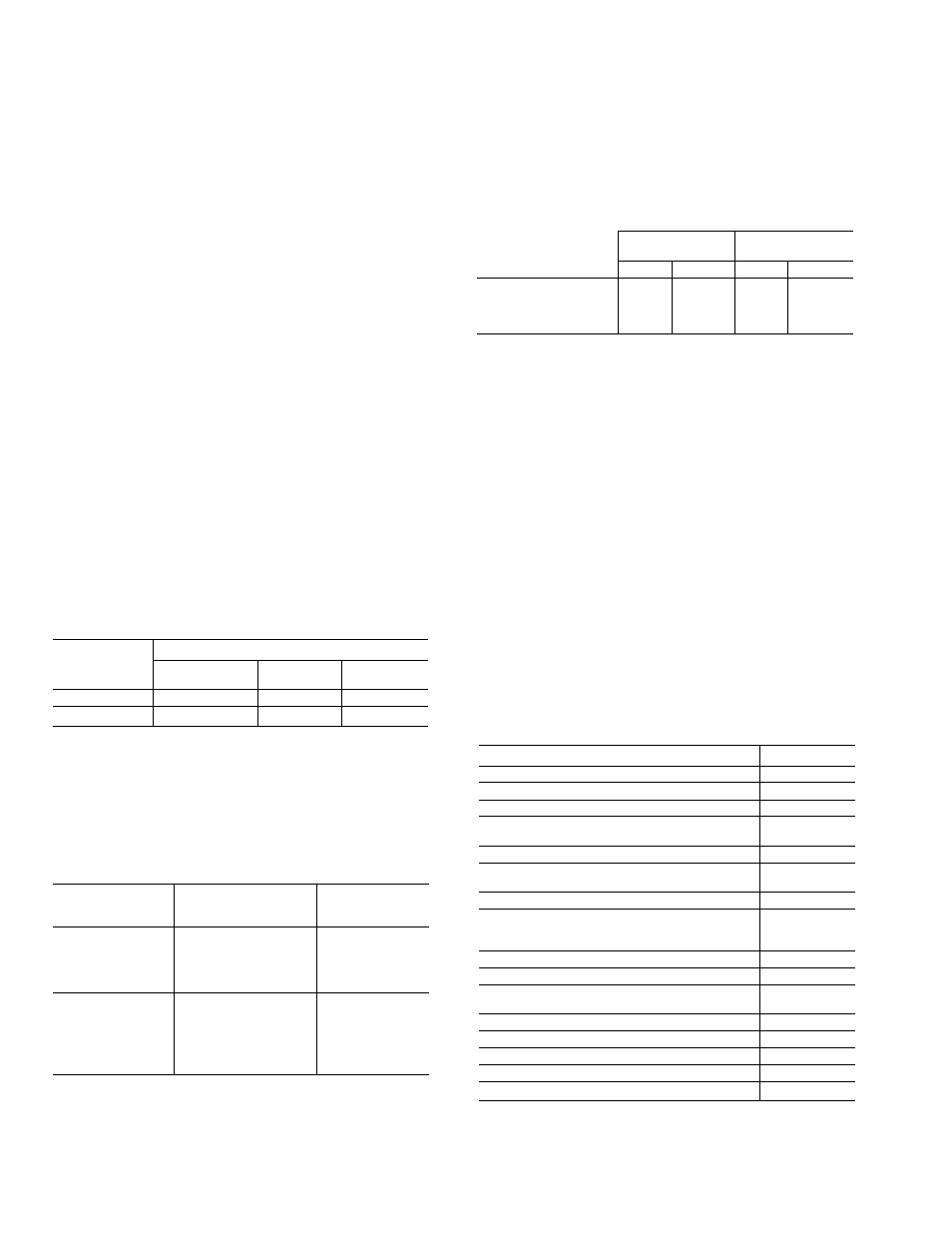

Table 1 — Unit 40RR Accessory Electric Heaters

ELECTRIC HEATER (3 PHASE 50/60 Hz)

PART NO.

Rated

Voltage

kW

FLA

40RT-900-101

240

20.0

48 0

40RT-900-111

480

21.8

26.0

LEGEND

FLA —

Full Load Amps

NOTES;

1. A maximum of 4 electric heaters can be used with the 40RR024

unit.

2 Electric heaters are not UL (Underwriters’ Laboratories) listed for

the 38QP/40RR heat pump.

WATTAGE MULTIPLICATION FACTORS

Heater Voltage

Rating

Actual Heater

Voltage

(3 Phase, 50/60 Hz)

Multiplication

Factor

200

0.69

208

0.75

240

220

0.84

230

0.92

240

1.00

380

0.63

400

0 69

480

415

440

0.75

0.84

460

0.92

480

1.00

INSTALLATION

Step 1 — Perform Outdoor and Indoor Unit

Installation — Follow the installation instructions pro

vided with each outdoor and indoor unit. See Table 2 for

maximum vertical elevation between the indoor and out

door sections.

Table 2 - Maximum Vertical Separation

HEIGHT OF INDOOR UNIT

SYSTEM

Above Outdoor

Unit

Below Outdoor

Unit

ft

m

ft

m

40RR024/38QP024,

60 Hz, Ckt 1 and 2

40RR024/38QP024,

50 Hz, Ckt 1 and 2

59

58

180

17.7

59

58

18.0

17.7

Step 2 — Size Piping Lines — Employ one of the

following methods to size interconnecting refrigerant pip

ing between the 38QP and the 40RR:

1. Use the pipe sizes shown in Refrigerant (R-22) Charge

and Piping Selection table in the 38QP installation in

structions (when not using field-installed accessory un

loaders).

2. Use the Carrier System Design Manual, Part 3, Piping

Design

(when

using

field-installed

accessory

unloaders).

3. Use the piping sizing portion of the Carrier E20-II com

puter program (when using field-installed accessory

unloaders).

NOTE: Liquid line solenoid valves are not required; they

are factory-installed on the 38QP.

Step 3 - Check Contents of Piping Package

— Install heat pump piping package to convert indoor coil

for heat pump service. Table 3 lists the contents of the pip

ing package. Figure 2 shows the contents of the piping pack

age in the approximate order in which they are installed.

Table 3 — Heat Pump Piping Package Contents

Example: 20.0 kW (at 240 v) heater on 230 v

= 20.0 (0.92 multiplication factor)

= 18.4 kW capacity at 230 v

DESCRIPTION

QUANTITY

Receiver, Piping Assy (Ckt 1)

1

Piping Assy (Ckt 2)

1

Filter Drier (Ckt 1 and 2)

2

Receiver, Piping Assy Support Bracket

(Cktl)

1

Filter Drier Support Bracket (Ckt 2)

1

TXV (Thermostatic Expansion Valve)

(Ckt 1 and 2)

2

Screw, Receiver Strap*

1

Screws, No. 10 for Filter Drier Strap (4)

5/8" Tube Clamp (2), Filter Drier Support

Bracket (2)*

8

Tube, Filter Drier to TXV (Ckt 1)

1

Tube, Filter Drier to TXV (Ckt 2)

1

Strapping, 11" Long for Filter Driers

(Ckt 1 and 2)

2

Strapping, 10" Long for Receiver (Ckt 1)

1

Clamp for 5/8" OD Tube (Ckt 1)

1

Installation Instructions*

1

Strap for TXV Sensort

2

Screw and Nut for TXV Strapt

2

‘Items are included in a packet which accompanies piping package,

titems are packed together with TXV.