Guide specifications, Electrical data (60-cycle) – Carrier 09DC User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

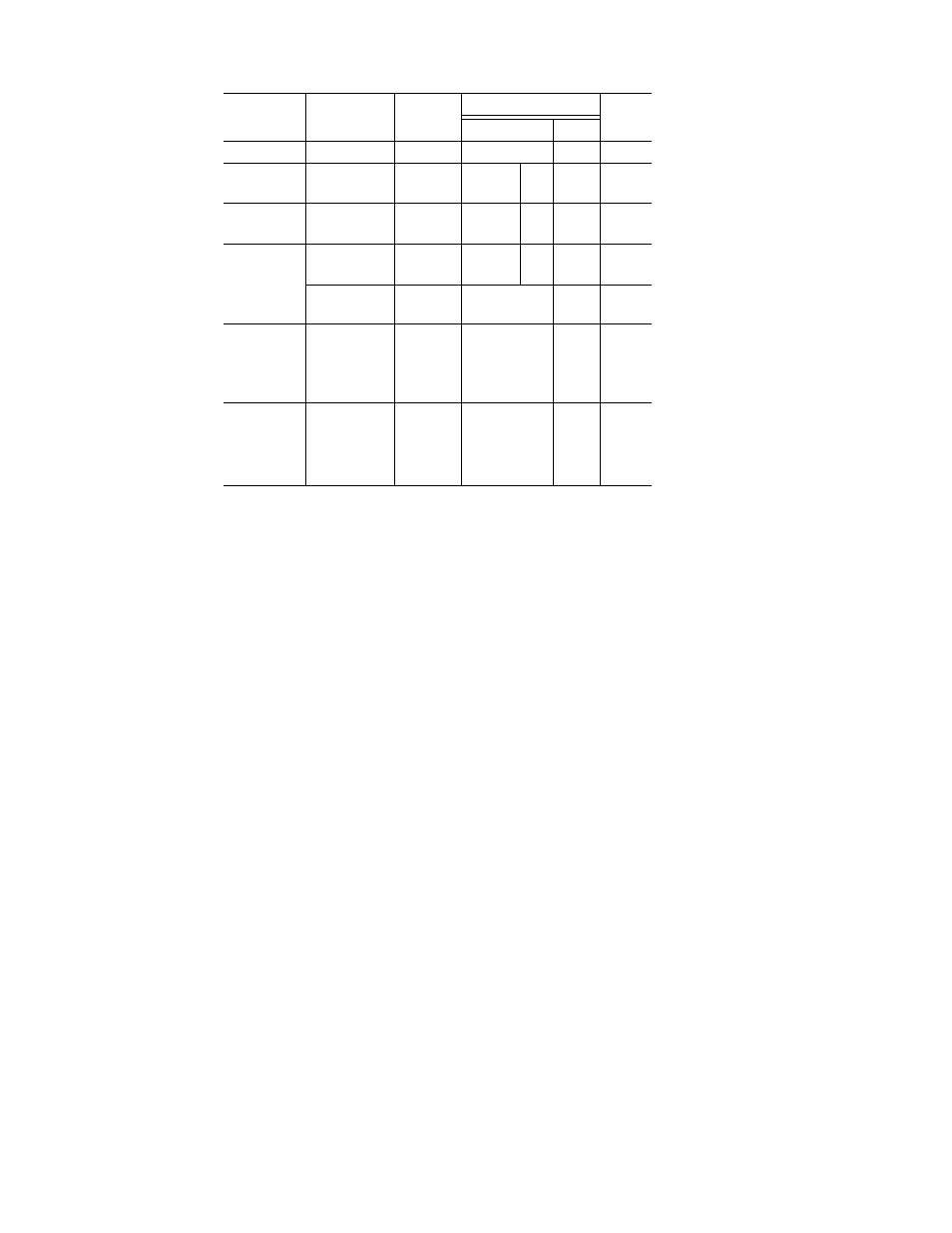

ELECTRICAL DATA (60-cycle)

FANS

FLA

UNIT

VOLTS

PHASE

No.

Hp

(ea)

9AB6

208/230

1

1

V

3

2 1*

9AB8

208/230

1

2

T otal

1

V

3

2.1*

208/230

1

/3

2.4

9AB12

208/230

1

2

T Ota 1

1

V

3

2.1*

208/230

1

1

%

2 4

208/230

1

3

1

V

3

3 3*

09DC016

208/230

1

T otal

2

V

2

4 0

460

3

3

V

2

1 2

575

3

1.0

208

3

4 0

230

3

3 8

09DC024

3

/4

460

3

1.9

575

3

1.6

208

3

5 3

09DC028,

230

3

3

4 8

034, 044

460

3

2 4

575

3

1 9

FLA

- Full Load Amps

*These are special motors suitable for use with Motormaster head pres

sure control.

NOTE:

All

208/230-volt

single-phase

units

are

suitable

for

operation

on

either

voltage.

GUIDE SPECIFICATIONS

Furnish and Install

as shown on the drawing—^—air

cooled condensers suitable for

tons each of total

heat rejection, when condensing refrigerant

at , F

saturated condensing temperature with air entering at«

F

dry-bulb

temperature.

Units

shall

be

arranged

for

hori

zontal (vertical) air flow.

Units

shall consist of: coils, with integral subcooling,

2.

supporting casing with stand, and wind deflector (9AB only).

Coil

shall

be

constructed

of

plate

aluminum

fins

on

mechani

cally

expanded

copper

tubes,

cleaned,

dehydrated,

sealed,

and

leak

tested

at

400

psig

(9AB),

410

psig

(09DC016),

or

420 psig (09DC024 and larger).

Fans

shall

be

direct

drive,

propeller

type,

protected

by

guards. Motors shall be permanent split-capacitor (9AB,

09DC016) or 3-phase, 60-cycle (09DC016, 024, 028, 034,

044,

054,

064,

084).

All

motors

shall

be

resiliently

mounted

and

prelubricated,

with

built-in

overload

protection.

Fan

shaft

shall

be

corrosion

protected

and

mounted

in

prelubri

cated

bearings.

Fan

blades

shall

have

an

iridite

finish.

A

magnetic contactor shall be field supplied for 9AB, 09DC-

3.

016, and shall be field supplied for 09DC024, 028, 034, 044,

054, 064, 084 if head pressure control is not used.

Casing

shall

be

painted,

Galvanneal

steel

(9AB,

09DC-

016)

or

heavy-gage,

double-weight

(2-1/2

oz

zinc/sq

ft)

galvanized

steel

(09DC024,

028,

034,

044).

Access

panels

shall be provided for electrical connections.

Accessories

(To specify from Items 1 thru 4 below, refer to

4.

Head Pressure Control Data table.)

1.

Motormaster

Electronic

Head

Pressure

Control

—

Units

shall

be

provided

with

a

completely

transistorized

vari

able

speed

fan

control

to

modulate

unit

capacity

in

re

sponse to variations in head pressure. The control en-

5.

Manufacturer reserves the right to change any

closure

shall

be

weathertight

and

shall

have

Weather

Armor

finish.

Mounting

hardware

shall

also

be

provided.

Control

shall

modulate

fan

motor

speed

from

full

to

zero

rpm

to

maintain

a

saturated

condensing

temperature

of

approximately

100

F

at

outdoor

temperatures

down

to —20 F.

Fan

Cycling

Control

—

Unit(s)

shall

be

provided

with

a

control

to

cycle

one

of

two

fans

(9AB8,12),

two

of

three

fans

(09DC016,024,028,034,044),

or

four

of

six

fans

(09DC054,064,084),

in

response

to

outdoor

ambient

temp

erature.

Control

package

shall

include;

thermostat

and

remote

bulb

(9AB8,12);

contactor(s),

terminal

strip(s),

plug,

and

two-stage

thermostat

(09DC016,024,028,034,

044);

contactors,

two-stage

thermostat,

power

control

terminal

blocks

and

two

quick-connect

receptacles,

one

at

end

of

10-foot

flexible

conduit

(09DC054,064,084).

Controls

shall

be

enclosed

in

weathertight

sheet

metal

box

with

cover.

Necessary

mounting

hardware

shall

be

provided.

Head

Pressure

Control

Damper

—

Unit(s)

shall

be

pro

vided

with

a

control

for

further

reduction

in

condenser

capacity

to

meet

system

part

load

operation

or

lower

outdoor

ambient

temperatures.

This

assembly

shall

in

clude:

flanged

damper

frame,

movable

damper

blades,

operating

linkages,

self-contained

pressure-operated

damper

actuator

with

capillary,

and

necessary

mounting

hardware.

Winter

Start

Control

(required

when

minimum

ambient

temperature

is

below

design

coil

suction

temperature)

—

Unit(s)

shall

be

provided

with

a

Winter

Start

Control

Package

which

shall

temporarily

bypass

the

system

low

pressurestat to permit start-up at low temperature.

Floor Mounting Stand (9AB8 and 12).

C A R R I E R A I R C O N D I T I O N I N G

product specifications without notice.

C O M P A N Y • S Y R A C U S E , N E W Y O R K

Tab 5

Form 9AB,09DC-2P Supersedes 9AB,09DC-1P

Printed in U.S.A.

2-66

Codes C and MC

(520902)