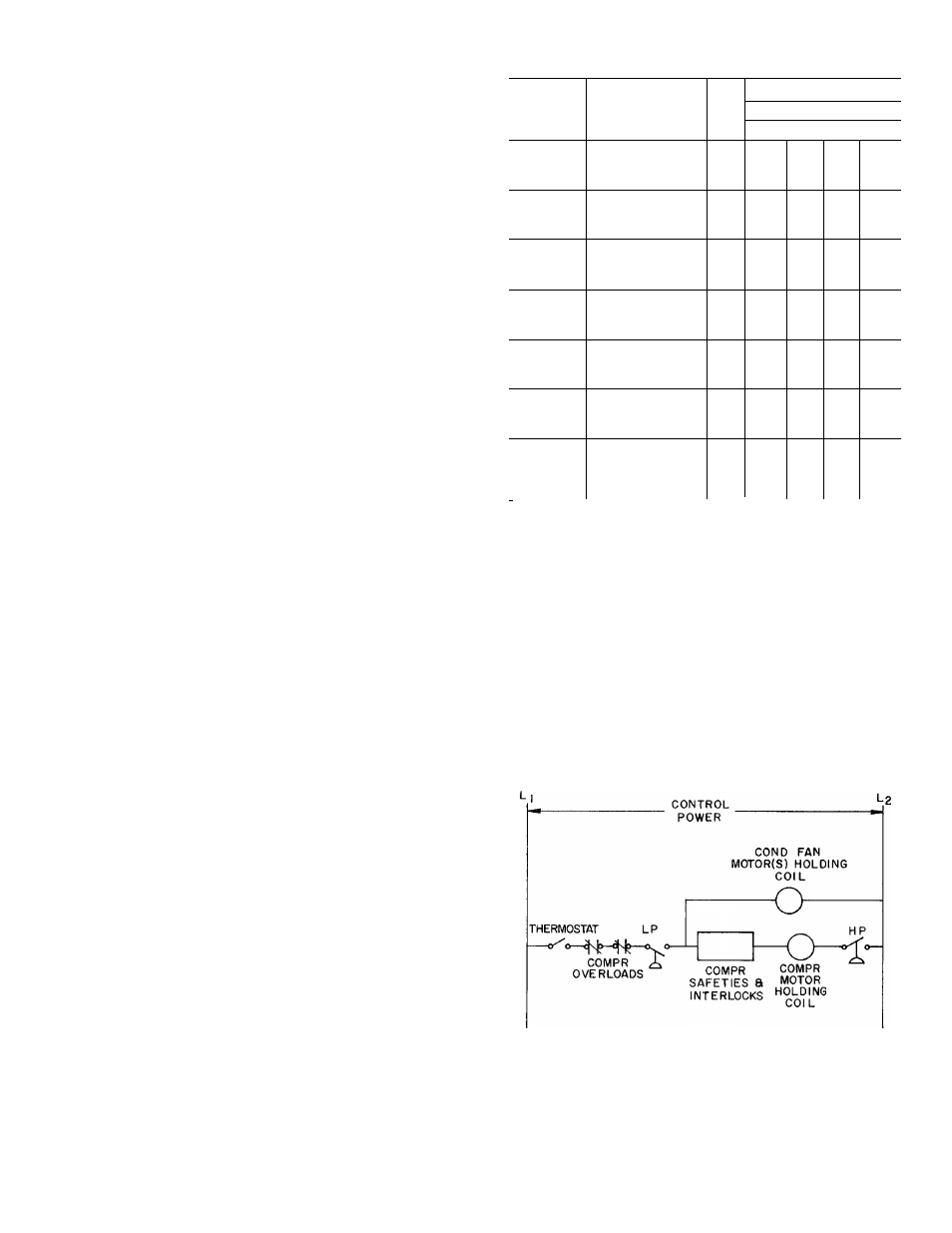

Schematic wiring diagram — condenser control, Head pressure control, Head pressure control data – Carrier 09DC User Manual

Page 4: Abs,ï2, 43 s2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

General

—

Efficient

operation

of

evaporator

expansion

valves

requires

a

90

F

minimum

condensing

temperature

for

100%

compressor

capacity,

80

F

for

75%

capacity,

and

70

F

for

50%

and

25%

capacity.

The

capacity

of

an

air-cooled

condenser

increases

with

increased

temperature

difference

(cond

temp

minus

entering

air

temp)

and

decreases

with

decreased

temperature

difference.

Therefore,

a

drop

in

en

tering

air

temperature

lowers

the

condensing

temperature

for

a

given

heat

rejection.

When

outdoor

air

temperatures

drop

below

prescribed

minimums,

some

form

of

head

pres

sure

control

is

required.

(See

Head

Pressure

Control

Data

table

for

minimum

outdoor

temperatures

and

specific

head

pressure controls for 9AB and 09DC units.)

HEAD PRESSURE CONTROL

9AB, 09DC Head Pressure Controls

— Head pressure on

9AB

and

09DC

condensers

may

be

controlled

by

the

Motor-

master

Electronic

Control,

by

fan

cycling,

or

by

fan

cycling

supplemented by the Motormaster or a modulating damper.

Motormaster

—

When

outdoor

temperatures

are

low

enough

to

cause

low

condensing

pressures,

the

Motormaster

modu

lates

the

motor

speed

of

one

condenser

fan

from

full

to

zero

rpm

to

maintain

a

constant

saturated

condensing

tempera

ture.

The

Motormaster,

available

only

with

single-phase

motors

(on

unit

sizes

thru

09DC016),

may

be

the

sole

con

trol

on

single

fan

units

or

may

be

used

in

conjunction

with

fan

cycling

control

on

multiple

fan

units

for

full

year-round

head pressure control.

Fan

Cycling

—

The

fan

cycling

control,

used

primarily

during intermediate seasons, cycles one fan or two fans.

On

two-module

condensers

(09DC034,

064,

024),

the

fan

cycling

control

cycles

four

of

the

six

condenser

fans

(two

of

three

in

each

module)

from

a

two-step

thermostat

respond

ing

to

variations

in

ambient

temperature.

The

first

step

of

the

thermostat

cuts

out

two

corresponding

fan

motors,

one

in

each

module;

the second

step

cuts

out a second

pair of cor

responding

fan

motors.

The

two

condenser

modules

are

controlled

from

a

single,

completely

wired

fan

cycling

con

trol

box

consisting

of

one

two-stage

thermostat,

one

power

and

one

control

terminal

block,

and

two

quick-connect

re

ceptacles (one at the end of a 10-foot flexible conduit).

Head

Pressure

Control

Damper

—

An

accessory

head

pressure

control

damper

is

available

to

supplement

the

fan

cycling

control

on

the

09DC024

and

larger

units.

The

09DC054,

064,

and

084

require

two

damper

packages

in

stalled

for

parallel

throttling

of

air

to

the

two

uncontrolled

fans.

Each

damper

assembly

has

a

pressure-operated

actu

ator

to

operate

the

damper

blades

which

modulate

inlet

air

flow

to

the

uncontrolled

fan

in

response

to

head

pressure

variations.

The

pressure

sensing

tubing

(capillary)

for

both

pressure

actuators

is

connected

to

the

same

point

in

the

liquid

line

serving

the

last

refrigerant

circuit

to

shut

down.

Each

capillary

is

provided

with

a

1/4-inch

flare

connection.

A

single

shut-off

valve

at

the

liquid

line

is

recommended,

for service.

Multiple

Circuit

Condensers

—

Multiple

circuit

conden

sers

applied

to

separate

refrigeration

cycles

present

special

problems

when

head

pressure

is

controlled

from

a

single

control

point.

For

such

applications,

more

positive

system

control

may

be

ensured

by

using

individual

condensers

and

head pressure controls.

HEAD PRESSURE CONTROL DATA

UNIT

SIZES

HEAD

PRESSURE

CONTROL

TD

COMPR CAP.

(%)*

100 75 50 25

Min Outdoor Temp

(F)t

All

None

30

25

20

60

65

70

57

61

65

55

57

60

62

64

65

9AB6

Motormaster

30

25

20

-20

-20

-20

-20

^ABS,Ï2

Far\

Ort i'<>>

3Q

2S

20 :

1 S3

i

43

52

38

45

52

42

4?

5i

'S3

9AB8,12

Fan Cycling,

One Fan with

Motormaster

30

25

20

-20

-20

-20

-20

024j,028,

OH 044i

С/с''в^ j,

Tw«^ FiTK,

: 30

: 25

ГС

3

30

26

!

m

1

4'i

43

S2

-

SS

09DC016

Fan Cycl ing,

Two Fans with

Motormaster

30

25

20

-20

-20

-20

-20

09DC024,

028, 034,

044t

Fan Cyc 1 ing,

Two Fans

With Mod Damper

30

25

20

-20

-20

-20

-2

13

25

Ш

Winter Season

TD

- Temperature Diff (cond temp minus ent air temp)

* Interpolation permitted.

t Based on 90 F minimum cond temp at 100% capacity, 80 F at 75%

and 70 F at 50% and 25%. (Motormaster holds cond temp to 100 ±

10 F at all loads and at temperatures down to -20 F.) On some ap

plications

with

multiple

DX

coils,

the

compressor

may

be

unloaded

while

individual

coil(s)

are

still

fully

loaded.

In

this

case,

expan

sion

valve

selection

must

be

based

on

condensing

temperatures

listed,

or

the

minimum

outdoor

air

temperature

must

be

raised

by

the

difference

between

listed

cond

temp

and

cond

temp

used

for

valve selection.

t Applied also to each module of 09DC054, 064 and 084.

SCHEMATIC WIRING DIAGRAM

— CONDENSER CONTROL

(Single Refrigerant Circuit, Single Phase)

LP

— Low Pressure Switch

^

HP

— High Pressure Switch

NOTES:

1. For three-phase service, holding coils are wired in parallel.

2.

Multicircuit

units

may

be

similarly

controlled

by

wiring

fan

motor

holding

coil(s)

in

series

with

thermostat,

compressor

overloads,

and low pressurestat of each refrigerant circuit

3.

Two

or

more

condensers,

piped

in

parallel

on

a

single

refrig

erant circuit, must be of equal size and wired in parallel.