Carrier 38EN User Manual

Installation and start-up instructions, 38en air-cooled condensing units

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

38EN

Air-Cooled Condensing Units

Installation and Start-Up Instructions

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install or service air conditioning equipment.

Untrained personnel can perform basic maintenance,

such as cleaning and replacing filters. All other opera

tions should be performed by trained service personnel.

When working on air conditioning equipment, observe

precautions in literature and on tags and labels attached

to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instruc

tions thoroughly. Consult local building codes and

National Electrical Code (NEC) for special installation

requirements.

A WARNING

Before installing or servicing system, always turn

off main power to system. There may be more

than one disconnect switch. Turn off accessory

heater power if applicable. Electrical shock can

cause personal injury.

#

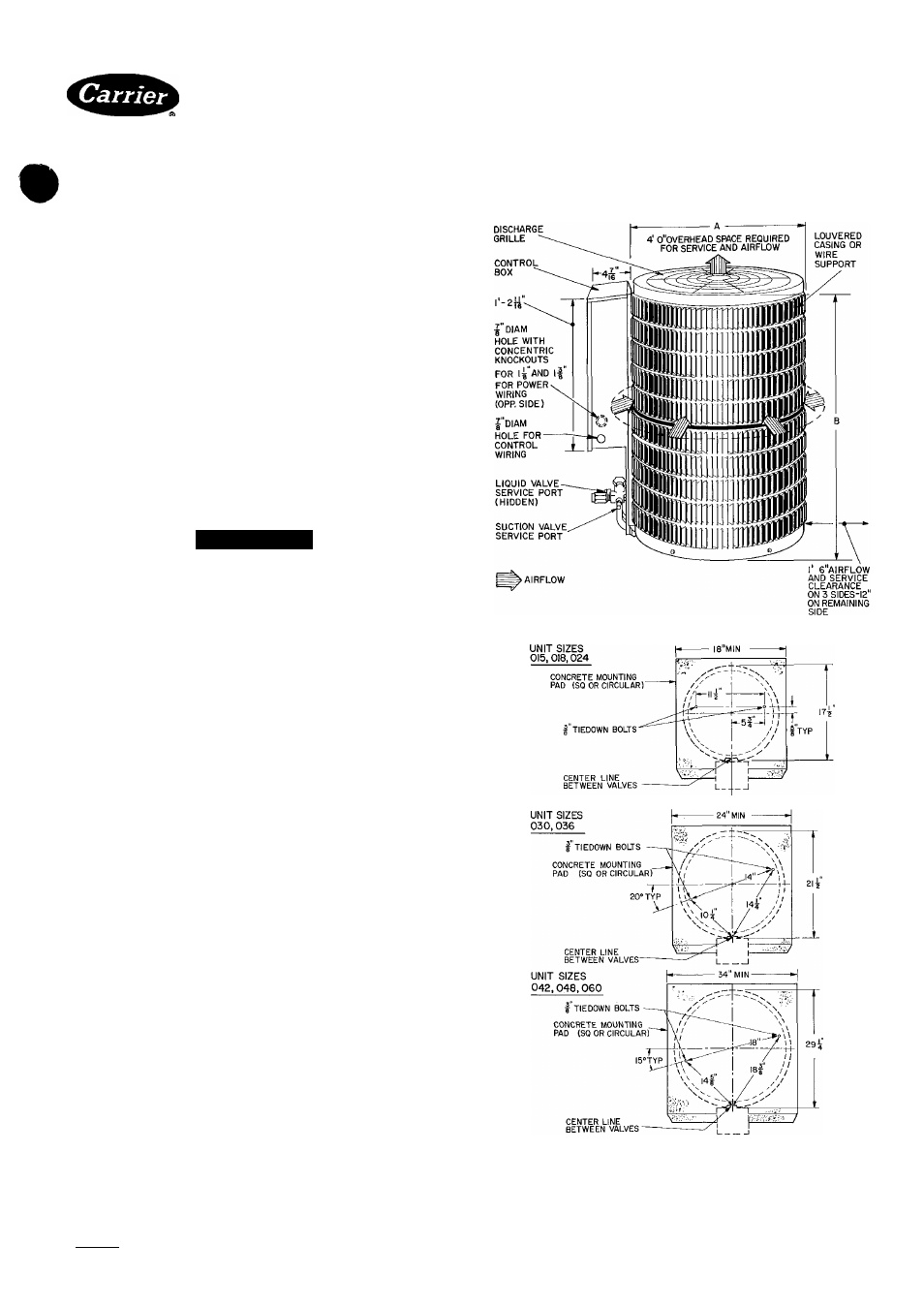

Step 1 — Check Equipment and Jobsite —

Install on a solid, level mounting pad. It is not recom

mended that unit be attached to pad using tiedown bolts.

Fasten unit to pad using holes provided in unit mounting

feet. See Fig. 1.

When installing, allow sufficient space for airflow

clearance, wiring, refrigerant piping and service. Main

tain a minimum of 4 ft clearance from obstructions above

and 18 in. on 3 sides of unit (12 in. on fourth side). Main

tain a distance of 24 in. between condensing units. Posi

tion so water or ice from roof or eaves cannot fall directly

on unit.

Step 2 — Replace Indoor AccuRater™ Piston,

if required.

REPLACE

ACCURATER

REFRIGERANT

CON

TROL PISTON in the indoor coil, if required, before

connecting refrigerant lines. Refer to Table 2 for proper

piston size.

Step 3 — Make Piping Connections — Outdoor

units may be connected to indoor sections using Carrier

accessory tubing package (refer to Service Data) or

field-supplied tubing of refrigerant grade, correct size

(see Table 1) and condition. For tubing requirements

beyond 50 ft, obtain information from your local

distributor.

Outdoor Units Connected to Carrier-Approved

Indoor Units — Outdoor units contain correct system

refrigerant charge for operation with indoor unit of the

same size when connected by 25 ft of field-supplied or

Carrier accessory tubing. Check refrigerant charge for

maximum efficiency (see Refrigerant Charging, page 4

and Service Data).

Certified dimension drawings avaiiabie upon request

Fig. 1 — Dimensions, Connections and

Mounting Pad (Refer to Table 1)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book И |4

PC101 Catalog No 563-825 PrintedinUSA Form38EN-3SI Pg 1

485

12-84 Replaces: 38EN-2SI

Pnr rAnlar^AmArtt Млтв iiea

Tab |3a|2a