Carrier, Installation – Carrier 50K User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Carrier

INSTALLATION

50K

TABLE 4

High Press. Switch

Low Press. Switch

Refrig.

Cut-In

Cut-Out

Cut-In

Cut-Out

22

284

364

83

46

500

218

265

67

30

NOTE* If the liquid refrigerant bleeds from the

liquid level check port on the receiver but

there is stUl flashing at the sight glass,

there is an indication that there is a re

striction in the liquid line or filter-drier.

Let the system operate for 20 minutes to balance

out and recheck the refrigerant and oil levels.

SPORLAN SEE-ALL MOISTURE AND

LIQUID INDICATOR

The moisture and liquid indicator must be full of

liquid refrigerant to properly indicate the moisture

content of the refrigerant. Operate the system at

least 30 minutes before attempting to determine the

moisture reading.

CHARGING PROCEDURE

The receiver has a bleeder port at the top to bleed

non-condensables from the system. There has to

be sufficient refrigerant in the system to make a

liquid seal at the outlet of the receiver to trap the

non-condensables in the top of the receiver before

the bleeder port can be effective.

WIRING

The crankcase heater elements, heater relays, and

the condenser fan relays are to be field wired. See

Wiring Diagrams.

The compiete refrigerant system should be evacuated

with a good vacuum pump before charging with refrig

erant. When charging, connect a cylinder of refrig

erant through a tee to a gauge and to the gauge port

on the compressor service valve. Have the cylinder

in the upright position to admit vapor only. Admit re-

refrigerant to break the vacuum in the system. Start

the compressor and modulate the valve on the cylinder

to keep the suction pressure slightly under 50 psig.

Charge the system until liquid refrigerant will bleed

from the liquid level check port on the receiver and

also until the sight glass is clear. *

The crankcase heater relays are single pole, single

throw, normally closed, relays . Each crankcase

heater element is to be energized when its respec

tive compressor is "OFF.”

The condenser fan relays (S.P.S.T. Normally open)

are to be mounted per the condenser Installation In

structions . The control voltage is supplied by the

base unit. Follow the right wiring diagram so the

condenser fans wUl continue to run if the compres

sor is shut down by one of its protective devices

and the thermostat is stUl calling for cooling.

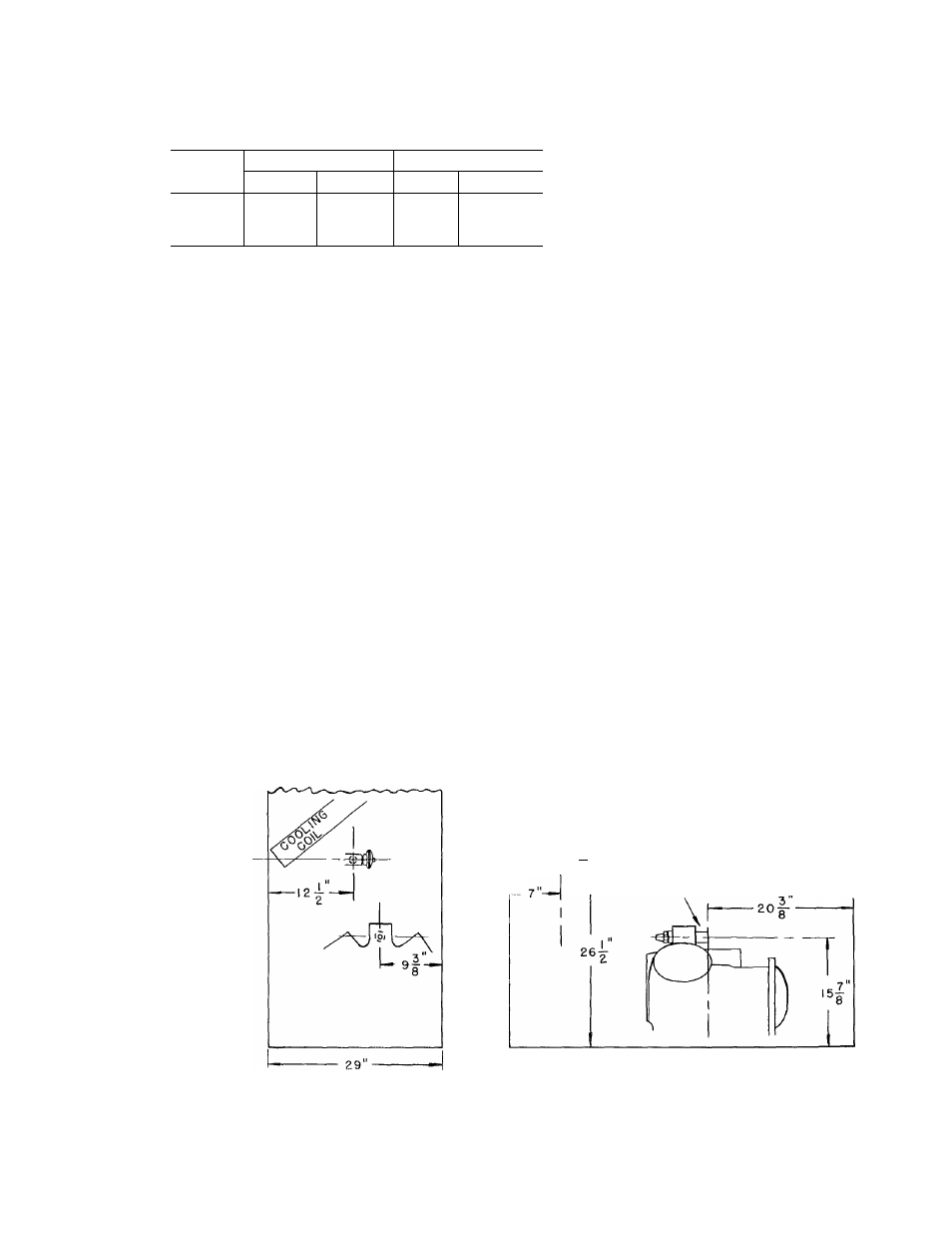

SIDE ELEVATION

FRONT ELEVATION

NOTE. ALL DIMENSIONS ARE TO

1

OUTSIDE OF CASING, NOT

I

TO OUTSIDE OF PANEL.

EXPANSION VALVE

EXPANSI

COMPRESSOR

DISCHARGE VALVE

48

FIG. 1 - LOCATION OF COMPRESSOR DISCHARGE AND LIQUID CONNECTIONS 50K8