Install machine supports – Carrier HERMETIC SCREW LIQUID CHILLERS 23 XL User Manual

Page 16

Install Machine Supports

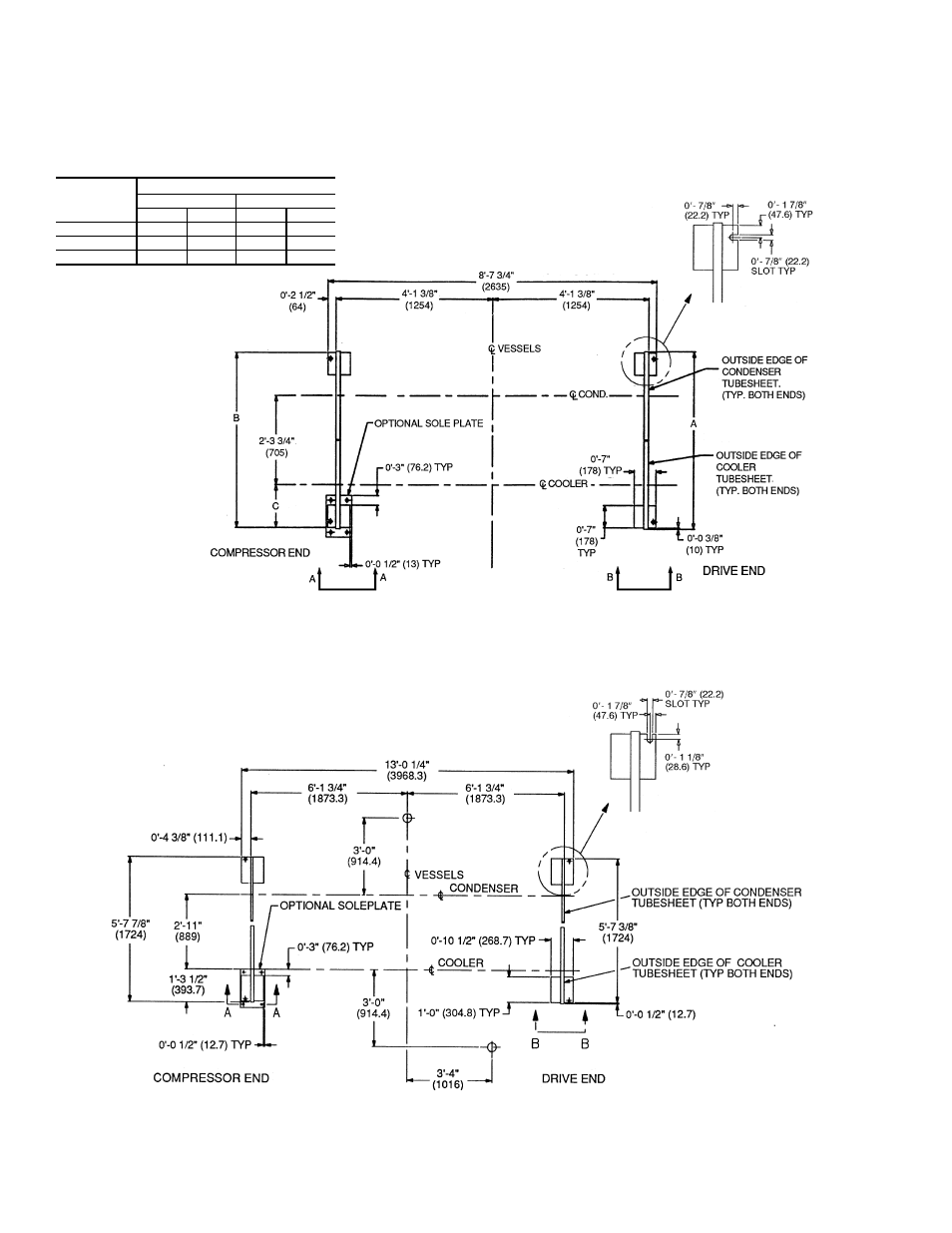

INSTALL STANDARD ISOLATION — Figures 13-18 show

the position of support plates and shear flex pads that form

the standard machine support system.

INSTALL OPTIONAL OR ACCESSORY ISOLATION (if

required) — Uneven floors or other considerations may

dictate the use of soleplates and leveling pads. Refer to

Fig. 13-18.

Level machine by using jacking screws in isolation sole-

plates. Use a level at least 24 in. (600 mm) long.

DIMENSION

HEAT EXCHANGER SIZE

10 or 11

20 or 21

ft-in.

mm

ft-in.

mm

A

4-5

1

⁄

4

1353

4-7

1

⁄

4

1403

B

4-4

1

⁄

2

1334

4-6

1

⁄

2

1384

C

1-0

3

⁄

8

314

1-1

3

⁄

8

340

NOTES:

1. Dimensions in (

) are in millimeters.

2. Use grout and package components to establish the level base line.

3. If chiller is set on concrete pad, electrical contractor is to locate conduit stub-ups outside of pad.

Approximate

location shown.

4. See Fig. 15 and 16 for additional information.

Fig. 13 — 23XL Machine Footprint (Frame 1 and 2 Machines)

NOTES:

1. Dimensions in (

) are in millimeters.

2. Use grout and package components to establish the level base line.

3. If chiller is set on concrete pad, electrical contractor is to locate conduit stub-ups outside of pad.

Approximate

location shown.

4. See Fig. 15 and 16 for additional information.

Fig. 14 — 23XL Machine Footprint (Frame 4 Machine)

16