D.c. electrical connections, Grounding – Winco ULPSS40/I WITH DSE 7310 ENGINE CONTROL (2014) User Manual

Page 11

11

4030-00

60706-50

Minimum Conductor Sizes between the Generator and the ATS.

Based on wire type and temperature rating. Wire has been

derated for 40

o

C ambient temperatures.

Cu Conductor

Al Conductor

C/B Wire Temperature Rating

kW Voltage PH Amp 750C

900C

750C

900C

40 10/40 1 175 3/0 AWG /0 AWG 50 MCM 4/0 AWG

40 10/08 3 150 /0 AWG 1/0 AWG 3/0 AWG /0 AWG

40 10/40 3 15 1/0 AWG #1 AWG

3/0 AWG /0 AWG

40 77/480 3 60

#4 AWG #6 AWG

#3 AWG

#4 AWG

30 10/40 1 15 1/0 AWG #1 AWG

3/0 AWG /0 AWG

30 10/08 3 100 # AWG #3 AWG

1/0 AWG #1 AWG

30 10/40 3 90

# AWG #3 AWG

1/0 AWG # AWG

30 77/480 3 45

#6 AWG #8 AWG

#4 AWG

#6 AWG

1 10/40 1 90

# AWG #3 AWG

1/0 AWG # AWG

10/08 3 70

#3 AWG #4 AWG

# AWG

#3 AWG

10/40 3 70

#3 AWG #4 AWG

# AWG

#3 AWG

5 77/480 3 45

#8 AWG #8 AWG

#8 AWG

#8 AWG

For additional information on wire sizing refer to table 310-16 of

the National Electrical Code ANSI/NFPA 70.

C - Ground Lug, These ground lugs are bonded to ground

and are provided for you to connect your ground wire from the

transfer switch to. The lugs on the 40 kW will handle wire sizes

#6 AWG to 50 MCM and should be torqued to 50 in. lbs. The

lugs on the 1/30 kW will accommodate #6 AWG to 50 MCM

and should be torqued to 50 in. lbs.

D. 120 Volt Terminal Block, This terminal block is provide for

the 10 volt/ 15 amp feed from customers distrubution panel for

the block heater and the trickle charger.

****************

***** WARNING *****

****************

A main line circuit breaker has been provided inside the

generator housing. During all wiring installations make sure the

breaker is in the off position and the generator operation switch

is in the off position.

****************

***** WARNING *****

****************

EQUIPMENT DAMAGE - When installing a Three Phase 240

volt system be sure you know which lead is the high voltage

“wild” leg (208 Volt line to neutral). The generator normally

carries the high voltage on the G2 lead.

The load current carrying wires (L) and (T) must be sized to

handle the maximum load current without excessive voltage

drop. By code, the wire must be heavy enough to handle the

full current rating of the main line circuit-breaker (or fuse) in the

entrance (or sub-panel) protecting the contactor switch.

All wires should be installed in rigid or flexible conduit.

(Knockouts are provided in the control box).

See the manual shipped with the Automatic Transfer Switch for

connection locations in the switch. Connections in each switch

will vary depending on the type of switch and the manufacturer.

GROUNDING

A grounding lug has been provided on the engine generator set

to grounded to earth ground if required. Check with your local

codes. Generally a 8 foot copper rod driven into the earth will

provide a proper earth ground.

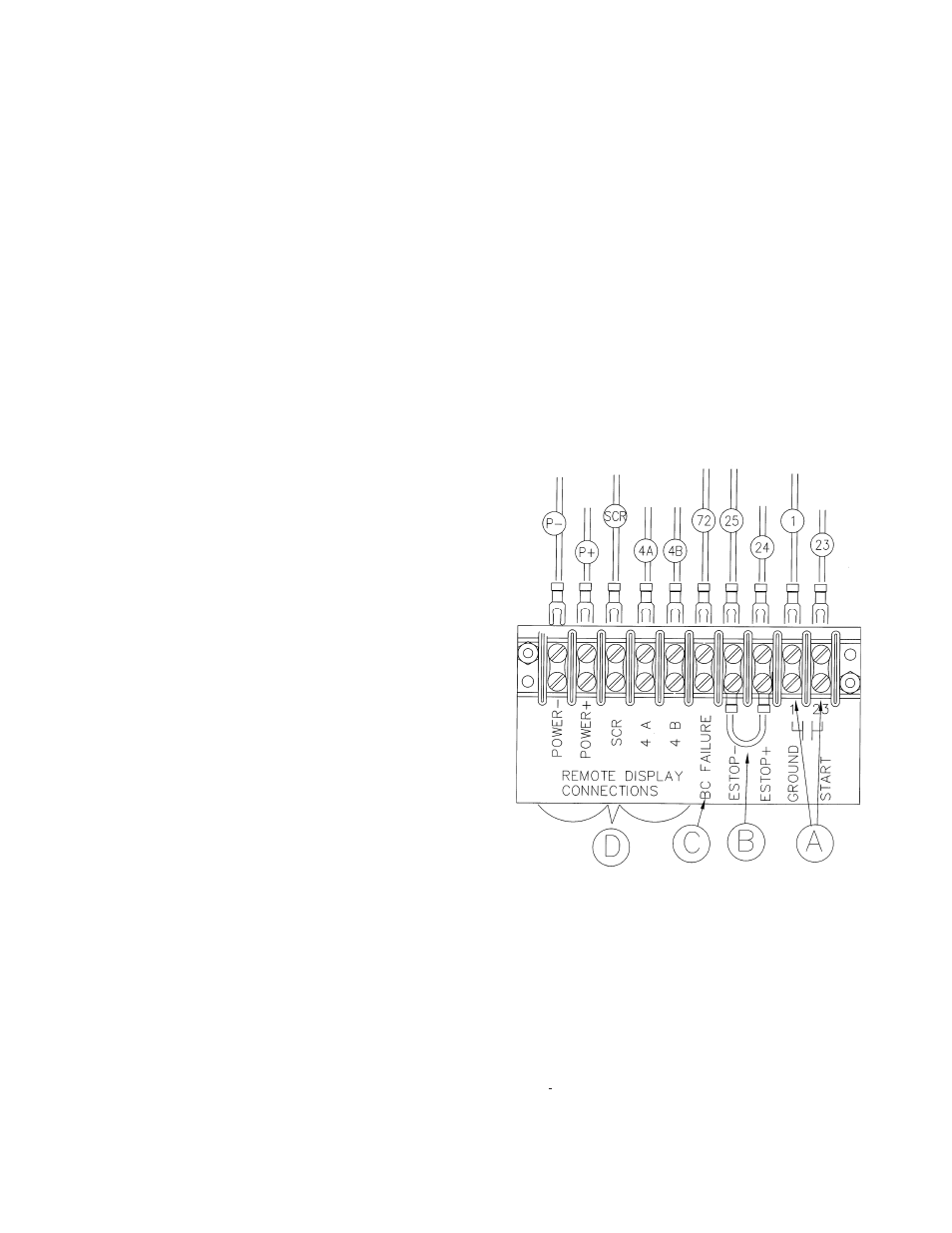

D.C. ELECTRICAL

CONNECTIONS

NOTE:

There are various DC connectors on the engine that have

nothing connected to them. This was done intentionally,

these connectors are for END OF LINE TESTING and

other diagnostic tests. They are not used during normal

operations and can just be ignored.

All DC connections are completed on the terminal strip just below

the engine control cabinet.

A - Customer Remote Start CONNECTIONS TERMINALS.

The two remote start leads from the Automatic Transfer Switch

are connected to the two terminals marked 1 & 3. The wire

in terminal labeled #1 is Battery Negative and the wire in the

terminal labeled #3 is your Remote Start lead. Closing these

two leads together will signal the DSE 7310 to go into an auto-

start mode and start up the engine generator.

Depending on the distance, 14 to 16 gauge stranded wire

should be used. It is suggested that these wires be labeled S1

and S3. The terminal blocks are designed to use terminal lugs

on all wires and the screws should be torqued to 9.6 in. lbs.