Replacing the diaphragm – VACUUBRAND MV 10 User Manual

Page 40

page 40 of 51

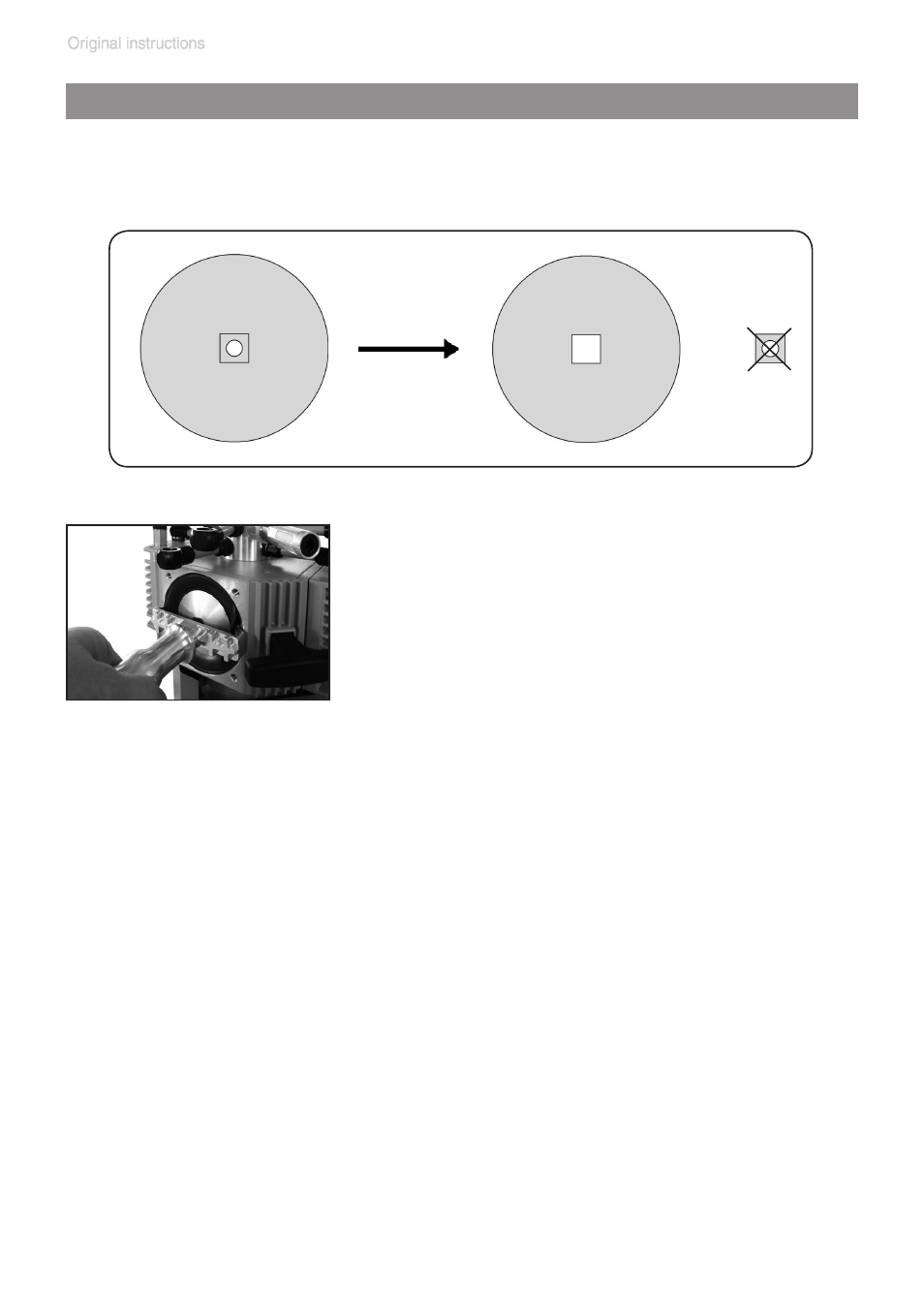

Replacing the diaphragm

➨

Remove the punched part in the centre of the new diaphragm when

replacing a diaphragm with square hole (see below).

+

+

Check diaphragm (F) for damage and re-

place if necessary.

➨

Lift diaphragm carefully sidewise.

+

Never use a pointed or sharp-edged tool to

lift the diaphragm.

➨

Use the diaphragm key to grip the diaphragm

support disc (G) below the diaphragm.

➨

Unscrew diaphragm support disc (G) with diaphragm (F) and dia-

phragm clamping disc (E).

➨

Check for washers (H) between the diaphragm support disc (G) and

the connecting rod (I). Do not mix the washers from the different pump

heads, since these are set at the factory to ensure proper pump per-

formance. Make sure that the original number is reassembled at the

individual pump head.

+

Too few washers: The pump will not attain vacuum specification. Too

many washers: Diaphragm clamping disc will hit head cover, causing

noisy operation and possibly causing the pump to seize up.

+

If the old diaphragm is difficult to separate from the diaphragm support

disc, immerse assembly in naphtha or petroleum ether. Do not inhale

vapors!