Figure 11 10, Figure 10 figure 9b figure 9a – Trending Accessibility BARRIER FREE SHOWER PAN User Manual

Page 6

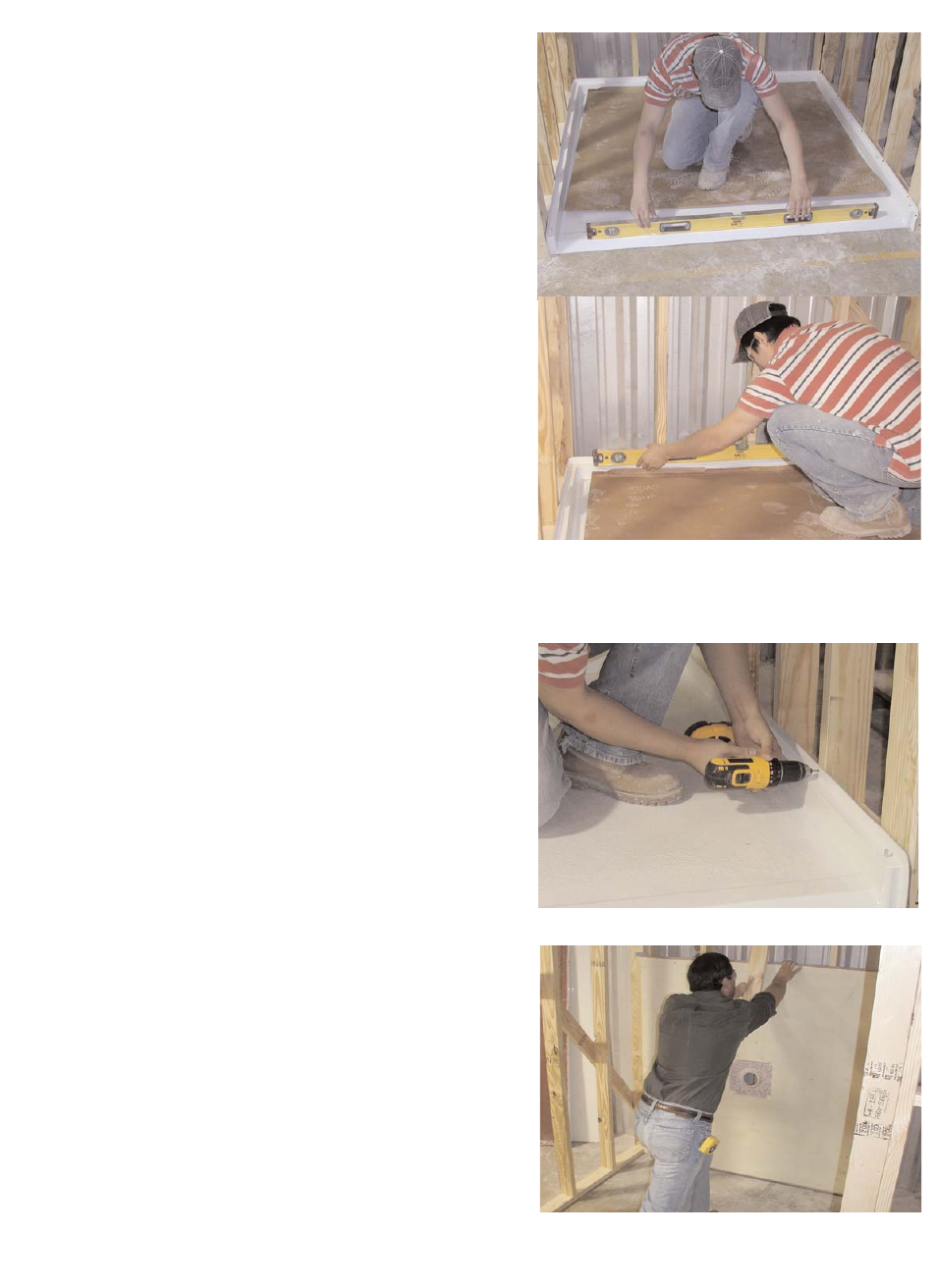

12.

The next step is to permanently install the

shower pan. A helpful tip to make this easier is to

rotate the pan upward and lean against the back framing

studs of the pocket. This will remove the pan from the

work zone without removing it from the stud pocket. Do

not secure the pan to the studs at this point because you

may need to reach around the pan as you install the

drain fitting detailed in the next step. Make sure pan is

angled enough so it will not fall.

13.

Install the drain fitting on the shower pan.

Apply a bead of 100% silicone caulking around

the recessed molded drain area on the finished side of

the pan. Remove the nut and all gaskets from the drain

body. Slip the threaded shank of the drain body through

the hole. Follow the instructions provided with the drain

fitting to install the gaskets in the proper location. When

all gaskets and Locknut are in place on the bottom side

of the shower, tighten the nut to secure the shower drain

assembly. From the top side of the drain assembly,

remove the rubber caulking gasket that will fit around

the drain pipe until the installation is complete. This will

allow the drain pipe to slip with the floor slope unit it is

properly braced.

A diagram of a typical drain assembly is shown on

Page 10 of this manual.

6

Figure 11

10.

Confirm the pan is level by using a long level on

top of the threshold, and along the sides and back.

Note the level is used on the finished horizontal surfaces

along the back and both sides. (See Figures 9A and 9B).

11.

Drill holes through the mounting flanges into each

framing stud. These holes should be drilled using a

1/8” drill bit. (See Figure 10).

Note: Plan on using flat or pan head screws to secure the

shower pan. A minimal screw head exposure will allow for

easier installation of wall board and finished wall materials.

(Wall materials furnished and installed by others).

Wipe away any excess caulking that may have squeezed

out on the inside of the pan.

If the pan is not level, shim the appropriate areas

to achieve level. Do not shim more than 1/8”. If

shimming over 1/8” is required, remove the pan

and correct the sub-floor area by

“floating” a floor leveling compound.

Figure 10

Figure 9B

Figure 9A

856-488-9535 www.TrendingAccessibility.com