Installation guide, For adjustable fusion shower pan on wood joists, Step 30 – Trending Accessibility Adjustable fusion shower pan on wood joists User Manual

Page 11: Step 29, Tiling guide, Step 28

Installation Guide

www.trendingaccessibility.com

11

for adjustable fusion shower pan on wood joists

Step 29

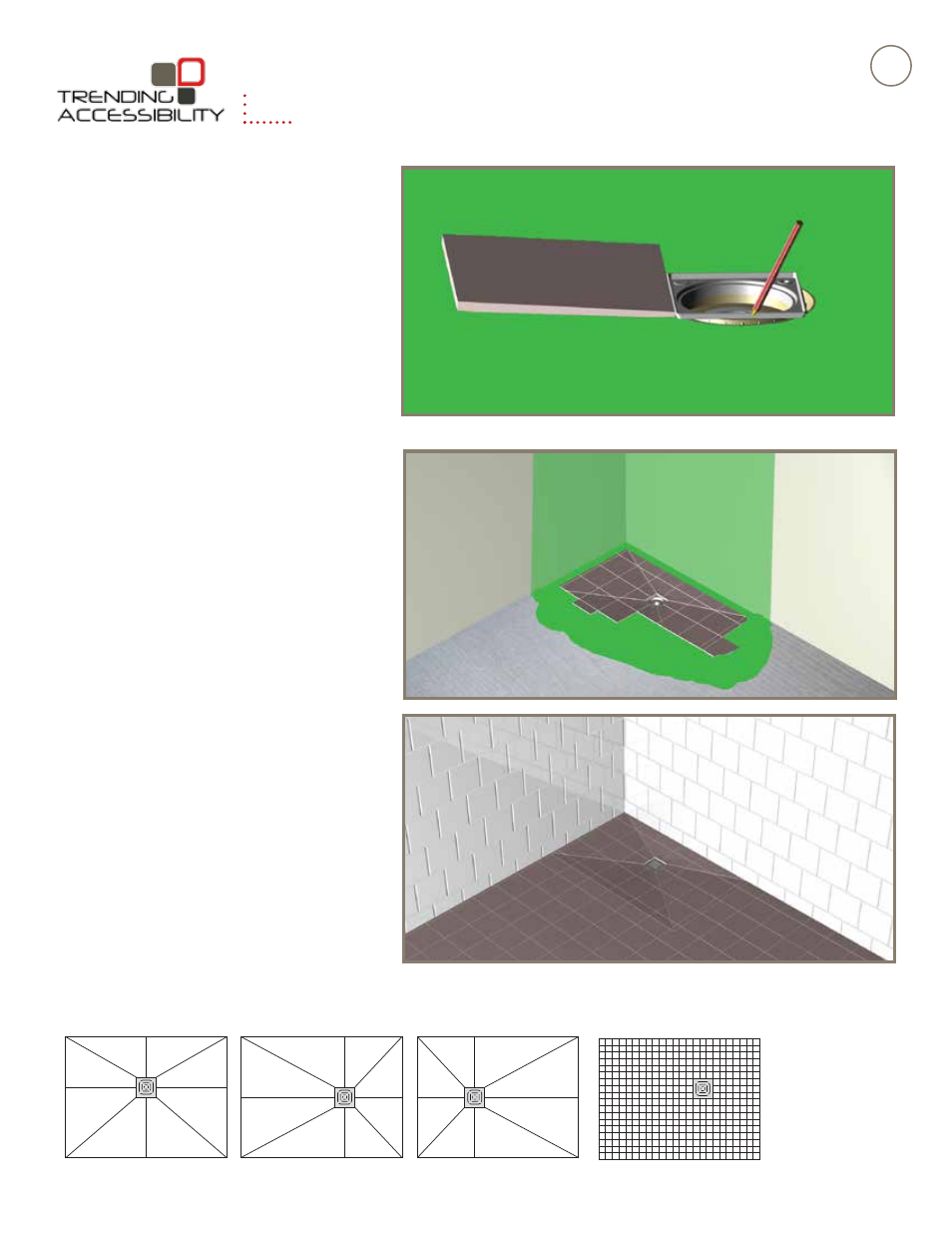

The metal grate frame can be rotated to match the

direction of the tile.

You are now ready to tile. If you are using large

format tiles, they must be cut diagonally and laid

to follow the pitch in the Fusion Pan (From the

corners of the grate frame to the corners of the

Fusion Pan). Use Tiling Guide below.

Apply the tile adhesive, and lay the tiles in a regular

pattern.

Step 30

Once your tiling is complete, grout the floors and

walls. Finalize by adding the drain grate. It is a

friction fit and must be pressed all of the way in.

Your Fusion Pan installation is now complete.

Enjoy!

Tiling Guide

Standard drainage position

Drainage position less than 90° to the right

Drainage position 90° to the right Drainage position 90° to the left

If you cannot rotate the drainage point a full 90°,

left or right, it is best to use smaller tiles

(maximum size 2.75” square) or mosaic tiles.

Standard drainage position

Drainage position less than 90° to the right

Drainage position 90° to the right Drainage position 90° to the left

If you cannot rotate the drainage point a full 90°,

left or right, it is best to use smaller tiles

(maximum size 2.75” square) or mosaic tiles.

If you cannot rotate

the drainage point

a full 90ଂ, left or

right, it is best to

use smaller tiles

(maximum size

2.75” square) or

mosaic tiles.

Step 28

The height adjustment ring and floor drain bowl

must now be fixed together using solvent cement.

Because solvent cements sets very rapidly we

strongly recommend the adjustment is done “dry”

first.

To set the permanent height of the grate frame,

place a floor tile beside the frame. Rotate the frame

until the height is about 1/16” higher (this accounts

for adhesive thickness). Now mark the position

of the adjustment ring. This mark shows the

final height position. Remove ring, apply solvent

cement, and re-align components to your marked

position. It is best to hold securely until pieces are

fully bonded.