Wind zone ii wind zone iii wind zone i – Tie Down 59070 Eye Anchor Kit User Manual

Page 3

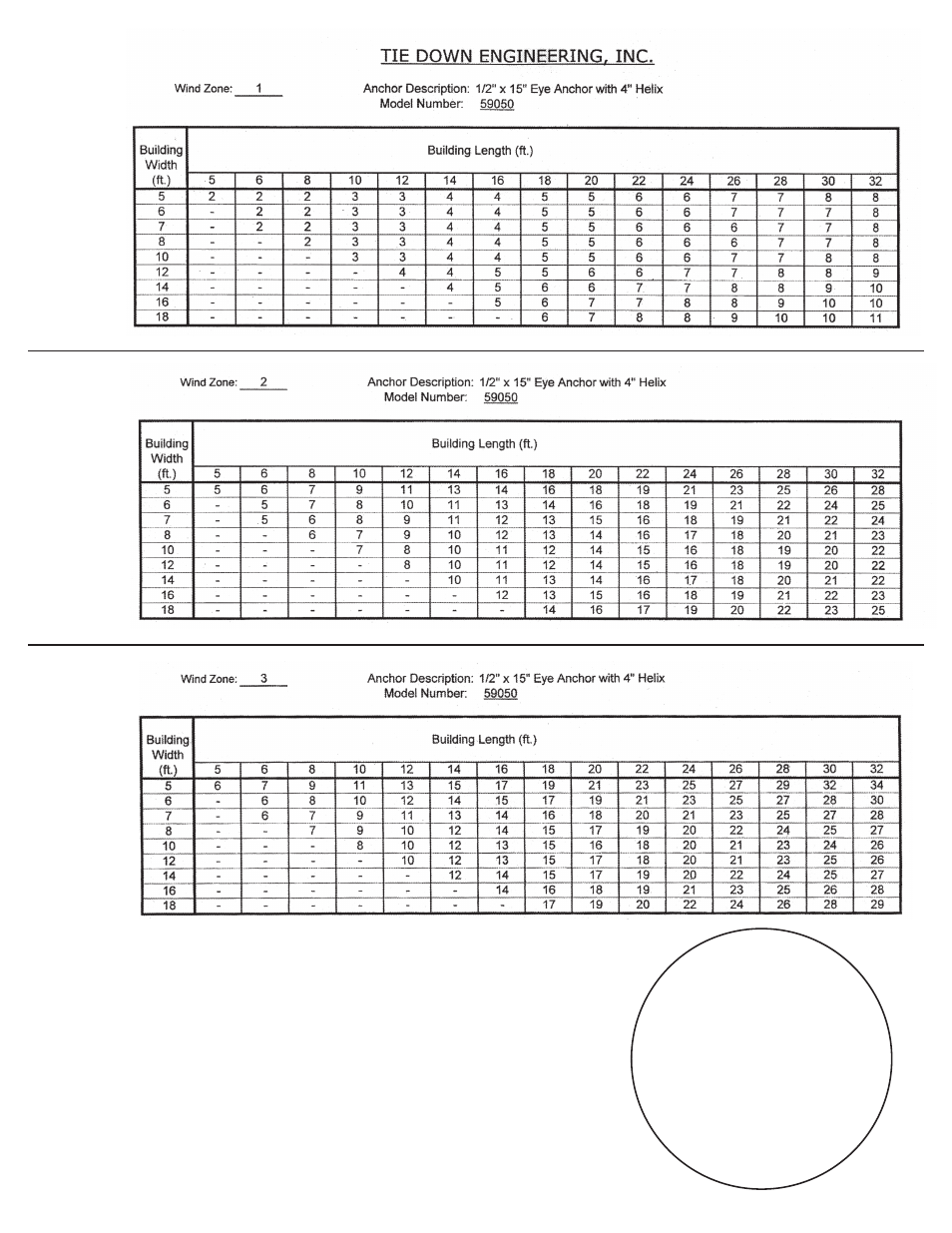

WIND ZONE II

WIND ZONE III

WIND ZONE I

Notes:

1) Maximum 102” building height.

2) One anchor shall be placed at each corner of building.

3) Any required anchors between corners shall be spaced equidistant

apart from each other.

4) Number of anchors required per side shall be determined by finding

quantities listed in columns.

See also other documents in the category Tie Down Hardware:

- 660E (16 pages)

- 750E (16 pages)

- LP750 (16 pages)

- 850E (16 pages)

- Drum Brakes (12 pages)

- Torsion Axle (4 pages)

- Eliminator Vented Disc Brakes (12 pages)

- G5 (12 pages)

- Super Lube Hubs (4 pages)

- Vortex Hubs for Spindles (4 pages)

- 66 Actuator (8 pages)

- 70 Actuator (1 page)

- 66 Actuator For Serial #16020 and above (8 pages)

- 66 Weld-On Actuators (2 pages)

- 70 Brake Actuator (8 pages)

- 70E (8 pages)

- 70LP (8 pages)

- 75LP (8 pages)

- LP850 (16 pages)

- 85 Actuator (8 pages)

- 80 Actuator (8 pages)

- 80LP (8 pages)

- 125 Alien Actuator (8 pages)

- 125 Actuator (8 pages)

- 145 Raptor Actuator (8 pages)

- 165 Raptor Actuator (8 pages)

- LP16.5 (8 pages)

- 20 Raptor Actuator (8 pages)

- Back Flow Style Brake Solenoid (1 page)

- Brake Line Kit for "Add On Axles" (2 pages)

- Brake Line Kit for Single Axles (2 pages)

- Brake Line Kit for Tandem Axles (2 pages)

- Brake Solenoid Kit for use with Tie Down's Brake Actuator (1 page)

- Drum Brake Kit for Electric Brakes (4 pages)

- Drum Brake Kit (4 pages)

- Replacement Brake Shoes (4 pages)

- Trailer Brake Flush Kit (1 page)

- TSB - Drum Brakes (2 pages)

- Vortex Hub (2 pages)

- Wheel Hub Kit (1 page)

- Dust Cap (1 page)

- Replacing End Units on Eliminator Torsion axles (1 page)

- Turbo Lube Replacement O-Ring (1 page)

- Turbo Lube (8 pages)

- Spindles Procedure for Removing and Replacing Spindle Wear Sleeves (2 pages)