Tie Down 80 Weld-On Actuators User Manual

Page 2

Washer

Two angle plates set at 90˚ on the

underside of the master cylinder

“Tack” weld

(one on each side)

“Full” weld

(on both sides)

Trailer

Tongue

Washer

Two angle plates set at 90˚ on the

underside of the master cylinder

“Tack” weld

(one on each side)

“Full” weld

(on both sides)

Trailer

Tongue

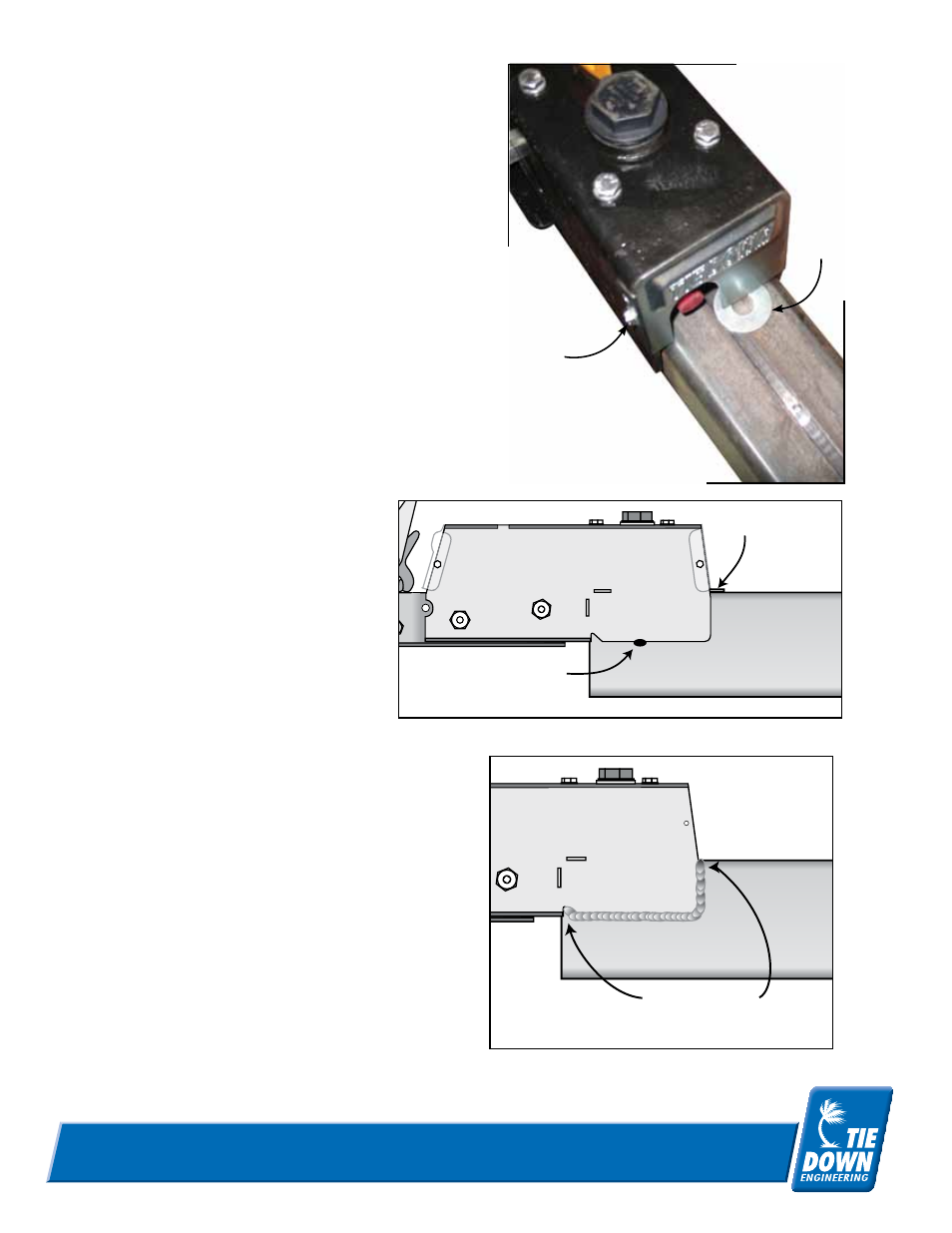

3. Place the supplied flat washer under the rear cover

as shown in pictures 3 & 4. The purpose of the

washer is to level the actuator on the tongue and

elevate the actuator slightly so that it does not rest on

the master cylinder.

4. Tack weld the actuator on both

sides to hole the actuator in place

(picture #4).

5. Remove the rear cover and

the flat washer (picture #3).

6. Weld 1/4” fillet as shown on both sides of the

actuator (Picture #5).

7. replace rear cover

Follow actuator instructions for filling accutator

master cylinder, loading the dampener with brake

fluid and bleeding the brakes.

Picture #3

Picture #4

Picture #5

Washer

Rear Cover

(one screw on

each side)

4 color

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401