Sonics 1098 Press User Manual

Page 16

5. Lock the two column clamps, tighten the converter housing door screws,

and then tighten the fixture on the base plate.

6. Check for proper mating of fixture, parts, and horn. If the horn and part are

not in parallel contact, shim the fixture or adjust leveling screws as

required.

7. Set the PRESSURE regulator to a reading of 20 psig (140 kPa/1.4 bar) on

the pressure gauge. (Turn the PRESSURE knob clockwise.)

8. To check that the horn and parts are properly aligned, the horn needs to

be lowered. Read through the Operation instructions on page 16, and then

proceed to lower the horn as detailed. If the horn and parts are not

sufficiently aligned, then repeat steps 4 through 8. However, if you are

working with small, delicate parts, then fine adjustments can be made

using the positive stop adjustment knob as explained below.

POSITIVE STOP ADJUSTMENT

The positive stop is set to limit the downward travel of the horn to

approximately 75%. Readjustments may be required. Coarse adjustment of

the clearance between the face of the horn and part should be made using

the elevation control. Fine adjustment should be made using the positive stop.

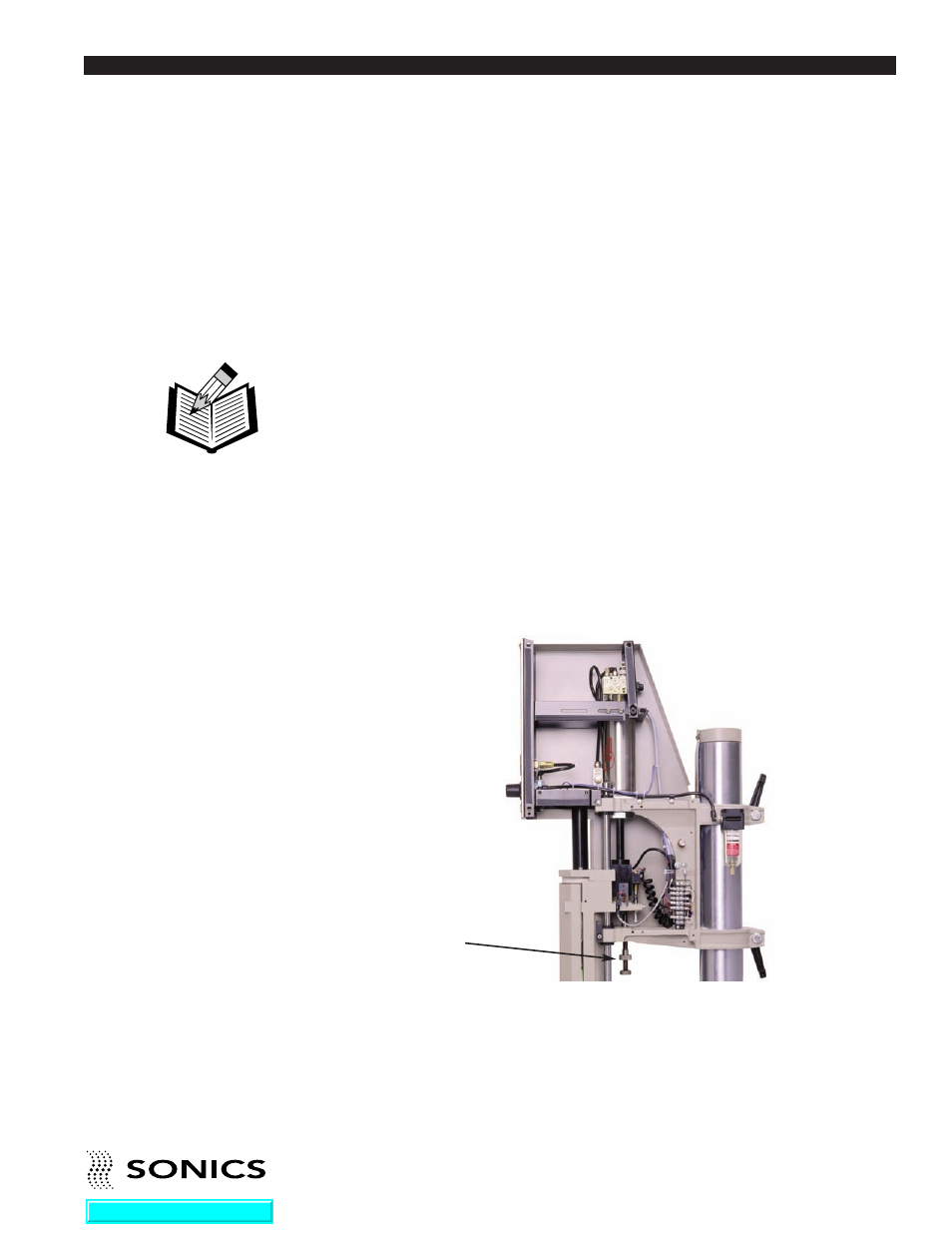

The positive stop adjustment knob is located offset from the converter

housing. Turning the knob clockwise will decrease downward travel distance.

Turning the knob counterclockwise will increase the downward travel

distance. Rotate the knurled thumbscrew to lock and unlock the positive stop.

POSITIVE STOP

ADJUSTMENT

KNOB

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

I N S T R U C T I O N M A N U A L • M O D E L 1 0 9 8

15

NOTE: For maximum

safety and productivity,

adjust the clearance

between the horn and the

part to a minimum that will

still allow ease of loading

and unloading.

Go To Top Of Document