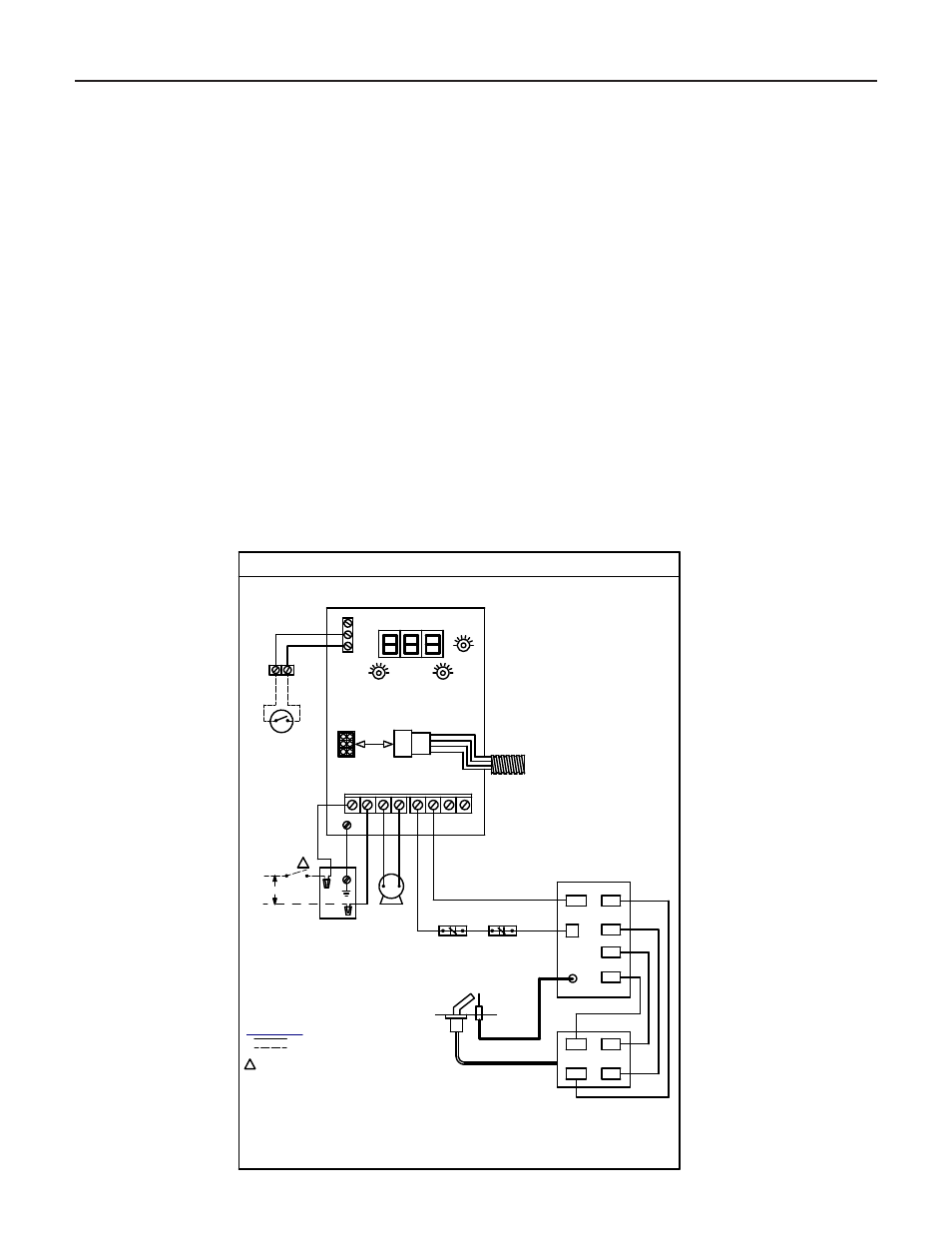

Sentinel, Figure 4 – Slant/Fin SE-245 User Manual

Page 7

7

Sentinel

ELECTRICAL WIRING

DANGER:

Before wiring, always turn off electric power supply,

otherwise shock or death can result.

1. Power Supply

A separately fused circuit is recommended. Use a standard

15 Amp. fuse or breaker and 14 gauge conductors in BX

cable or circuit.

Provide disconnect means and overload protection as

required. See boiler wiring diagram (Figure 4).

Boiler must be electrically grounded in accordance with

requirements of the authority having jurisdiction, or, in the

absence of such requirements, with the National Electrical

Code, ANSI/NFPA 70-latest edition.

2. Power Connection

Connect hot and neutral to L1 and L2 terminal of the boiler

control (See figure 4).

Connect ground wire to ground screw inside boiler control.

3. Thermostat Connections

Thermostat connections must be to T and TV screw

terminals of boiler temperature control (See Figure 4).

Thermostat Heat Anticipator Adjustments

If the 24v room thermostat that controls this boiler has an

adjustable heat anticipator, connect entire system to

thermostat and run the system while measuring the current

drawn through the thermostat wires. Set the heat

anticipator at the value measured. The set current should

match power requirements by zone valves and relays.

Add an additional 0.1 Amp to the measured currrent for vent

damper. Refer to the manufacturer’s instruction of zone

valve, vent damper and relays. Also, see instructions with

the thermostat.

4. Multi Zoning

For pump zoning system, see Figures 5 and 6, for zone

valve system, see Figure 7. DO NOT use control transformer

to power external accessories like zone valve and relays,

overload and/or burned-out transformer and boiler

malfunction can result.

5. Indirect External Water Heater

If system includes indirect water heater, the indirect signal

must be separated from heating zones(s) system. See figure

6 and 8. Follow steps below:

a. Connect end switch of the indirect water heater relay

to I1 and !2 of the boiler temperature control.

b. Connect end switch of the heating zones(s) relays to

T and TV of the boiler temperature control.

c. Power DHW and heating zone(s) circulators through end

switch relays as sgown on figure 6. Do not connect

heating zone(s) circulators to C1 and C2 of the control.

Note: For single heating zone with external indirect water

heaters, see figure 9.

CAUTION:

LABEL ALL WIRE PRIOR TO DISCONNCTION WHEN SERVICING CONTROLS.

WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

"VERIFY PROPER OPERATION AFTER SERVICING".

: PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED

WITH THE APPLIANCE MUST BE REPLACED.

IT MUST BE REPLACED WITH TYP 105` OR

ITS EQUIVALENT.

IGNITER CABLE

PILOT GAS PIPE

ELECTRIC

IGNITION

PILOT

CIRCULATOR

BLOCKED VENT

SAFETY SWITCH

ROLL-OUT

SWITCH

L2

L1

C1

C2

B1

IGNITION MODULE

24V(GND)

24V

I2

B2

VENT DAMPER

HARNESS

I1

WIRE LEGEND:

FACTORY WIRED

FIELD WIRED, FIELD SUPPLIED

I

MV-PV

MV

GND

PV

MV/PV

MV

GAS VALVE

GND

(BURNER)

PV

ECONOMY

HI TEMP

Z

T

TV

WIRING DIAGRAM FOR SENTRY & SENTINEL BOILERS WITH VESTIBULE

HYDROLEVEL HYDROSTAT CONTROL

MODEL 3200

PLUG

LO TEMP

24V

THERMOSTAT

NEUTRAL

120V/60Hz

HOT

JUNCTION

BOX

I

46 1115 000

RED

WHITE

BLK

BLUE

B

L

A

C

K

W

H

IT

E

B

L

A

C

K

G

R

E

E

N

GREEN

RED

W

H

IT

E

RED

RED

YELLOW

YELLOW

Figure 4