13 - use – Slant/Fin VSL-160C Part C User Manual

Page 7

79

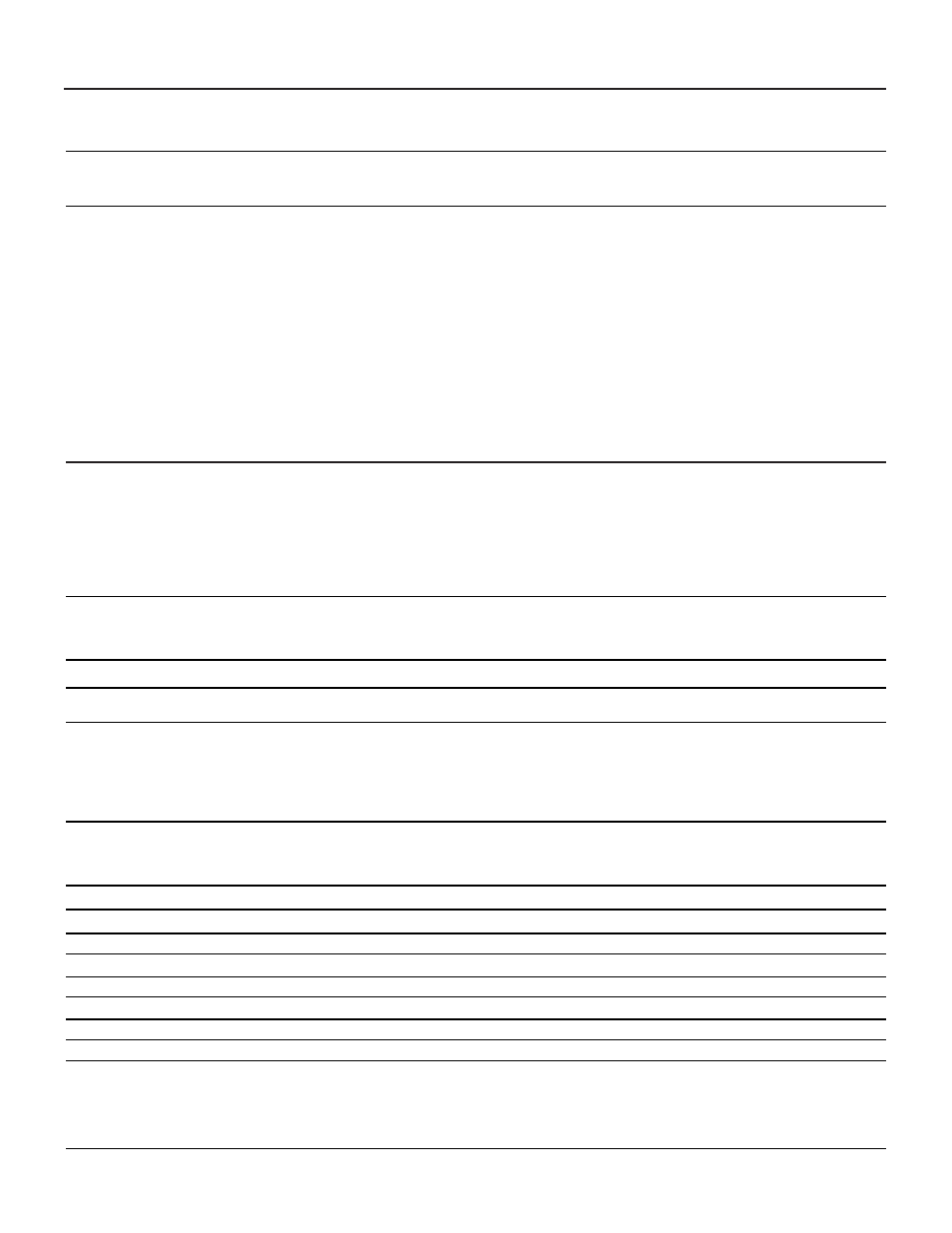

13.18.1 - Diagnostics: “L” lock-outs

“L”

Code

Lock-out

description

Checks to make

Solutions

L01

L02

L03

L04

13 - USE

L05

L06

L07

L08

L09

L10

L12

L13

L14

L15

L16

No fl ame detected after

three ignition attempts.

L17

Flame extinguishes three

times.

Boiler temperature is over

203° F (95°C).

Gas valve command relay

Safety relay

Flue gas sensor over

210°F (99°C)

Electrical circuit of fl ue

gas sensor is interrupted

Spark generator relay

RAM memory

E2prom memory damaged

E2prom memory damaged

Program error

Program error

Program error

Program error

The temperature

difference between the

U1 and U6 sensors is too

great

Check:

a-correct gas supply pressure (see

section 12.7);

b-ignition spark (see section 14.4);

c-correct combustion air pressure (see

section 12.8);

d-120Vac at the gas valve;

e-resistance of the two gas valve coils

should be 0.18 kohm and 1.1 kohm;

f- If the burner lights, but goes out at the

end of the ignition attempt, check: that

the ionization current is set at a value

greater than 60 (follow procedure in

section 14.12.4)

Check:

a-that the ionization current is set

at a value greater than 60 (follow

procedure in section 14.12.4);

b-check that gas valve open fast

enough;

a-Check that the circulator pump is

working;

b-Check if the water fl ow is not less than

5 GPM

Check for correct polarity of the wires to

the pump. Try to switch the wires.

Check:

a - that the electrical resistance of the

fl ue gas sensor complies with the graph

in Section 14.13;

b - that the effi ciency of the boiler is

over 86%

Check that the electrical resistance of

the fl ue gas sensor corresponds with the

graph in section 14.13;

Check that:

a - the electrical resistance of the two

sensors corresponds with the graph in

section 14.13;

b -check that the heating water fl ow is

not too low.

a-If the gas supply pressure is incorrect, it must be adjusted to

the correct pressure;

b-If spark is not present, check for correct ignition ectrode

position and gap as per section 14.4; If position is correct,

check for 120Vac at the supply of the spark generator.

c-if the combustion air pressure is incorrect, inspect the vent

system and eliminate any obstructions;

d-if the voltage to the gas valve is not 120Vac the power control

board must be replaced;

e-if the resitance of the gas valve coils is not 0.18 kohm and/or

1.10 kohm, the gas valve must be replaced.

f-If the ionization current is not greater than 60, confi rm that

the the CO2 content is adjusted properly (see section

12.9). Check the fl ame detection electrode (section 14.4)

and if necessary replace it, check the integrity of the fl ame

detection electrode electrical wires.

a-If the ionization current is not greater than 60, confi rm that

the the CO2 content is adjusted properly (see section

12.9). Check the fl ame detection electrode (section 14.4)

and if necessary replace it, check the integrity of the fl ame

detection electrode electrical wires.

b-Following procedure as per Section 14.12.4, check few times

if passing from low fi re to high fi re the fl ame estinguish. If

estinguish, change the gas valve.

a-If the circulator pump is bad, replace it, if is good, replace the

power control board.

b-If the water fl ow is less than 5 GPM check for any zone

valves that must be opened.

Replace the power control board

If the pump won’t run replace it. If the pump is good try to

replace the power control board.

a-If the fl ue gas sensor resistance does not correspond with the

correct values, replace it;

b-if the boiler effi ciency is less than 86% and the CO2 content

is correct, the primary heat exchanger has to be replaced

and proper water treatment methods employed to prevent

mineral build up on the water side

If the sensor resistance does not correspond with the correct

values, replace it;

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

a-If one or both sensors does not have the correct resistance

value, it must be replaced;

b-If temperature difference between U1 and U8 is higher than

55°F at maximum input, the heating water fl ow rate is too

low. The heating water fl ow rate must be corrected.