Troubleshooting (cont’d), Problem possible cause service instructions – SeaLand VHT 4500 Holding Tank - 140 Series VacuFlush Toilet User Manual

Page 14

14

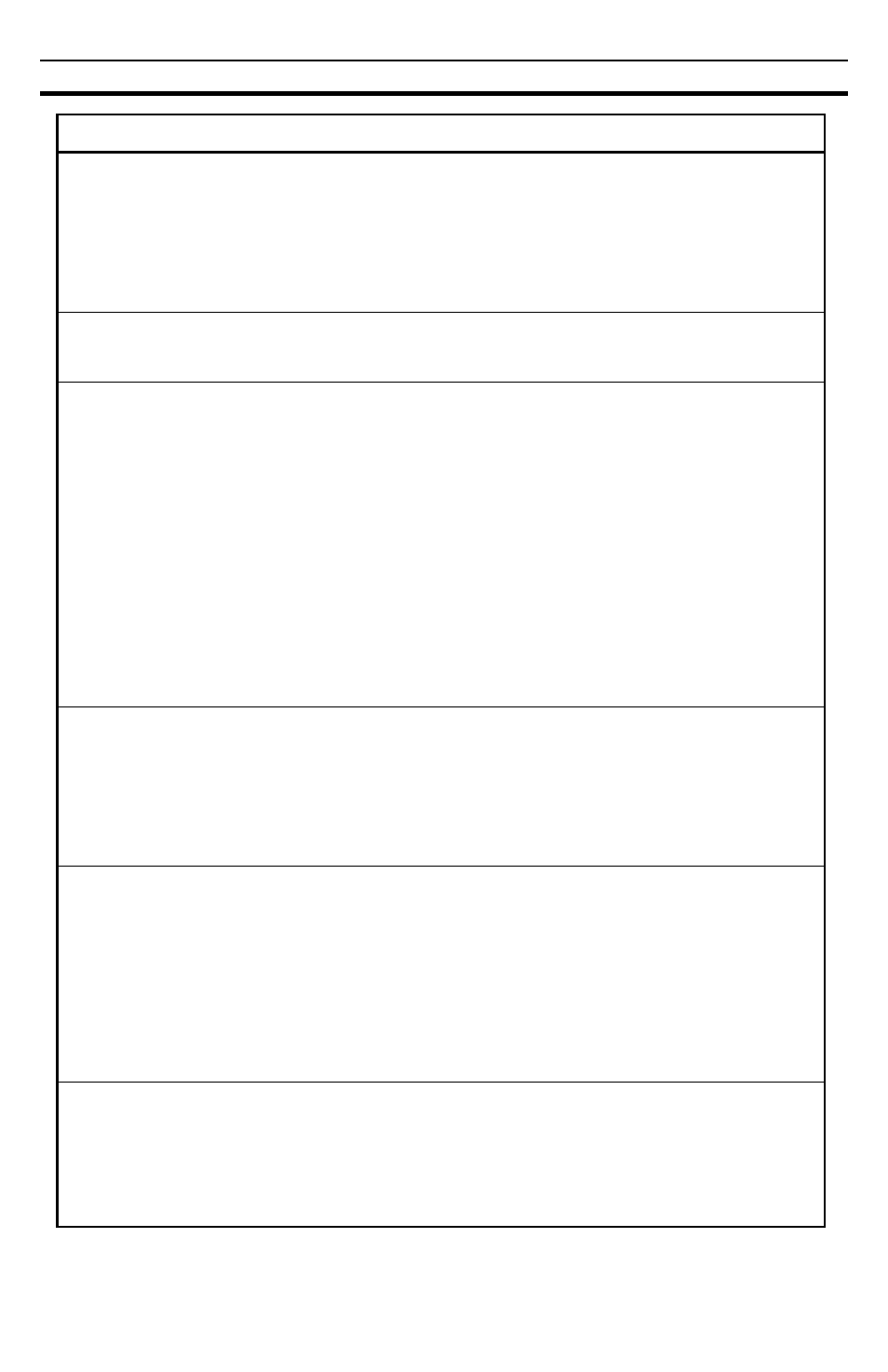

Problem

Possible cause

service instructions

TRoublEshooTinG (cont’d)

7. Water leaking from rear of

toilet bowl.

8. Water is leaking from the

base/toilet connection.

9. Vacuum pump running too

much between flushes.

10. Toilet will not flush.

(No vacuum.)

11. Vacuum pump will not run.

12. Vacuum pump will not

shut off.

a. Worn or defective vacuum breaker.

b. Loose vacuum breaker.

c. Cracked or defective toilet bowl.

a. Clamp ring may be loose.

b. Ball seals may be worn or

defective.

a. Flush ball in toilet leaks.

b. Vacuum line leak.

c. Foreign material has fouled air

pump valves.

d. Pump diaphragm worn or

damaged.

e. Duckbill valve in discharge fitting

stuck open.

a. Vacuum pump will not run.

b. Plugged vacuum discharge line.

c. Plugged vacuum pump valve.

d. Vacuum pump discharge or

intake lines plugged.

a. No power.

b. Loose or broken electrical

wiring.

c. Improper electrical

connections.

d. Faulty vacuum switch.

e. Faulty motor.

a. Insufficient vacuum.

b. Excessive vacuum leak.

c. Faulty vacuum switch.

d. Improper wiring.

a. Remove vacuum breaker cover

and look into top of vacuum

breaker. Flush toilet. If water

leaks during flush, vacuum

breaker needs to be replaced.

b. Secure vacuum breaker

connection.

c. Replace toilet bowl.

a. Tighten the clamp ring.

b. Replace ball seals.

a. Leave small amount of water in

toilet. If water drains from bowl,

see problems 1 - 2.

b. Tighten all hose connections

at pump, vacuum tank, holding

tank, and toilet.

c. Disassemble air pump and

inspect under the two flat disk

valves. If foreign material is

present, remove it and reas-

semble pump.

d. Inspect diaphragm in pump for

small hole or rip. Replace if

necessary.

e. Disassemble discharge outlet

and inspect duckbill valve.

Clean or repair if necessary.

a. See problem 11.

b. Blockage usually at base of toi-

let below flush ball. Disconnect

line and clear.

c. Inspect and clean pump valves.

Replace if needed.

d. Disassemble lines and clean.

a. Check input power, circuit

breaker and fuse.

b. Tighten or reconnect wires at

pump and vacuum tank.

c. Make certain wires at vacuum

switch are connected to the “B”

terminals.

d. To check vacuum switch, short

across “B” terminals with jumper

wire.

e. Replace motor.

a. Verify pump pulls minimum 10

in. Hg of vacuum.

b. See problem 9.

c. To check switch, remove one

“B” terminal wire.

d. Check wiring. Refer to Wiring

Diagram (page 8).