Installation instructions (cont'd), Install discharge panel (see figure 8), Attach label – Reznor BE Option - Installation - Polytube Adapter - Suspended Unit User Manual

Page 4: Install polytube (see figure 8), Installation checks

INSTALLATION INSTRUCTIONS (cont'd)

5. Install Discharge Panel (See Figure 8)

Slide the discharge panel over the front of the "box" formed by the sides, top, and

bottom adapter panels. Attach at all of the holes across the top, bottom and sides.

6. Attach Label

For future reference, attach the "Polytube Holes Location" label on the side panel of

the adapter. (See recommended location in Figures 2, 3, and 4 on page 2.) Wipe the

surface of the panel with a clean dry cloth. Remove the backing from the label and

adhere it to the adapter.

7. Install Polytube (See Figure 8)

The polytube adapter is now completed and ready for the field-supplied polytube.

Slip the end of the polytube over the collar under the tightening band. Be sure that the

air delivery holes are pointed in the proper direction. Fasten the band over the

polytube by tightening the adjusting screw.

The polytube should be suspended in accordance with the polytube manufacturer's

recommendations. General recommendations are that the first suspension point be

10 feet from the heater and that additional suspension be provided at approximately

8-foot intervals.

Polytubes are normally supplied as a tube which is open at both ends. The end

opposite the heater must be closed to permit the tube to inflate.

8. Installation Checks

When the installation is completed, the motor load and discharge air temperature

should be checked. Consult the installation manual supplied with the heater for

information on checking motor load and how to make blower speed adjustments.

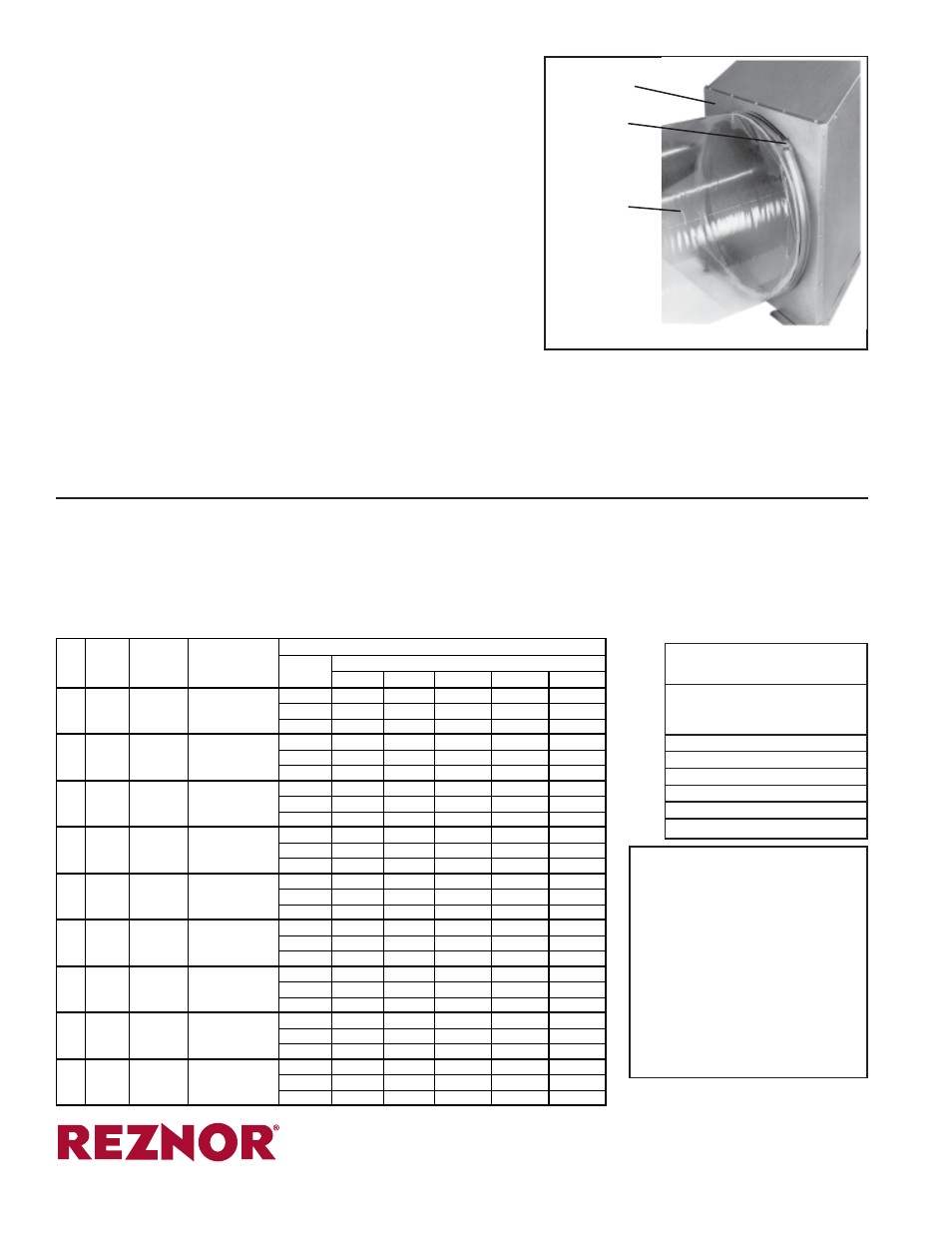

Discharge

Panel

Band with

Adjusting

Screw

Polytube

Ductwork

Figure 8 - Attach

Discharge Panel

and Polytube

Ductwork

WARNING:

Optional

polytube adapters are to be

used only on units equipped

with a blower. At no time

should the free area in the

polytube be less than the

listed minimum. Failure to

comply with this warning

could result in severe

personal injury, death, and/or

property damage.

Use a temperature measuring device to check the discharge

air temperature. Check the air temperature at a location in

the tube, six to eight feet way from the heater. A tempera-

ture rise range of 55

o

to 65

o

F is recommended. Following

the instructions in the heater manual, adjust the speed of the

blower to achieve the desired range while maintaining motor

current draw below the full load amperes shown on the

motor rating plate.

Conversion Table

(Diameter to Area)

Diameter

Area

of the Hole

of the Hole

(inches)

(square inches)

2-1/2

4.91

2-1/4

3.98

2

3.14

1-7/8

2.76

1-1/2

1.76

1

0.785

POLYTUBE SELECTION - Polytube selection is the responsibility of the installer. Different grades, hole positions, hole sizes, and lengths are

available. Some local code authorities require that polytube material be a listed material. Consult code authority having jurisdiction and polytube

supplier to determine the appropriate polytube material and recommended methods of suspension. Polytubing can be obtained from a supply

distributor such as FOF Products, Inc., P. O. Box E, 1505 Racine Street, Delavan,WI 53005; Acme Engineering company, P. O Box 978, Muskogee,

OK 74402; or any local greenhouse supply distributor.

The total open or free area of the polytube is important. Polytube suppliers have a great deal of flexibility in placement and sizing of holes. Too small

of a free area will cause overheating. Excessive open area may not permit the tube to inflate. See the table below for a guide in hole size and location.

Spacing and hole size may be varied, but free area must not be less than shown for your heater size.

(800) 695-1901, www.RezSpec.com

©2014 Reznor, LLC. All rights reserved.

Printed in the U.S.A.

MANUFACTURER OF GAS, OIL, ELECTRIC HEATING AND VENTILATING SYSTEMS

Trademark Note: Reznor

®

is registered in the United States and other countries.

0514 POD OG Form I-B-PS (Version 0.1)

CFM at Polytube

Minimum Free

Suggested Hole Sizes and Locations

Size .25"

Diameter

Area (square

Length of Polytube

ESP

(inches)

Inches)

50 Ft

75 Ft

100 Ft

125 Ft

150 Ft

Number

37pairs

75 pairs

75 pairs

75

925

18

110

Diameter

1-1/2"

1"

1"

Spacing

16"

12"

16"

Number

50 pairs 50 pairs 100 pairs

94 pairs

100 1235

18

145

Diameter

1-1/2"

1-1/2"

1"

1"

Spacing

12"

18"

12"

16"

Number

40 pairs 60 pairs

60 pairs

125 pairs

125 1540

18

185

Diameter

1-7/8"

1-1/2"

1-1/2"

1"

Spacing

15"

15"

20"

12"

Number

40 pairs 60 pairs

60 pairs

125 pairs

130 1600

24

190

Diameter

1-7/8"

1-1/2"

1-1/2"

1"

Spacing

15"

15"

20"

12"

Number

50 pairs 50 pairs

75 pairs

75 pairs

75 pairs

165 2035

24

240

Diameter

1-7/8"

1-7/8"

1-1/2"

1-1/2"

1-1/2"

Spacing

12"

18"

16"

20"

24"

Number

42 pairs 42 pairs

60 pairs

60 pairs

100 pairs

200 2465

24

300

Diameter

2-1/4"

2-1/4"

1-7/8"

1-7/8"

1-1/2"

Spacing

14"

21"

20"

25"

18"

Number

40 pairs 60 pairs

60 pairs

60 pairs

60 pairs

250 3085

24

360

Diameter

2-1/2"

2"

2"

2"

2"

Spacing

15"

15"

20"

25"

30"

Number

75 pairs 75 pairs

75 pairs

75 pairs

75 pairs

300 3700

24

425

Diameter

2"

2"

2"

2"

2"

Spacing

9"

12"

16"

20"

24"

Number

60 pairs 60 pairs

60 pairs

100 pairs 100 pairs

400 4935

24

550

Diameter

2-1/2"

2-1/2"

2-1/2"

1-7/8"

1-7/8"

Spacing

10"

15"

20"

15"

18"

Holes