LAARS Mighty Therm LO-NOx PW (Sizes 500-1825) - Install and Operating Manual User Manual

Page 9

Mighty Therm Lo-NOx

Page 9

pressure should be at least 15 psi (102.2 kPa) above

the water vapor pressure corresponding to the elevated

water temperature.

Heating boilers are not suitable for open systems

unless the supply water temperatures are kept below

180°F (82°C), and a minimum of 5 psi (34.1 kPa)

static head is maintained at the boiler.

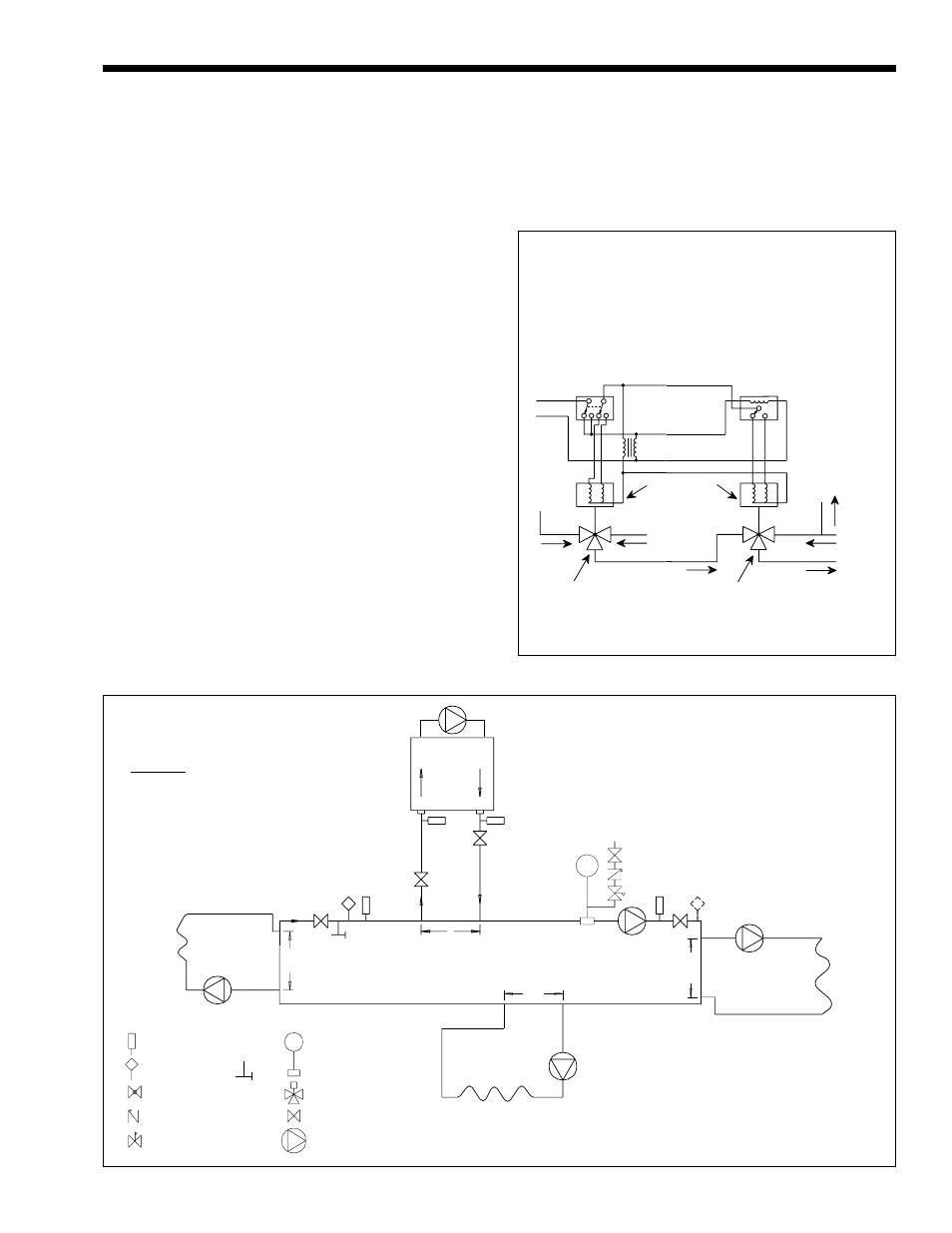

3.2.3 Hot/Chilled Water Systems

When a boiler is connected to an air

conditioning system where the same water is used for

heating and cooling, you must prevent chilled water

from entering the boiler When changing such a system

from cooling to heating, allow the chilled water to

circulate through the building, after the chiller has

been turned off, for a period long enough for the water

to warm up to at least 105°F (41°C) before the water

flows into the boiler. It is equally important to prevent

hot water from entering the chiller. The system shown

in Figure 8 is suggested to make sure the system water

is neither too hot nor too cold when a changeover

takes place. When a boiler is connected to heating

coils located in air handling units (where they may be

exposed to refrigerated air circulation), install a flow

control valve or other automatic means to prevent

gravity circulation of chilled water through the boiler.

Chilled water in the boiler will create condensate on

the boiler tubes. Boilers installed in violation of the

foregoing may void the warranty.

Figure 9. Primary-Secondary Plumbing.

Boiler Circulation

Pump

Cold Water

Make-Up

System Pump

12"

Max.

12"

Max.

12"

Max.

12"

Max.

Thermometer

Temperature

Sensor

Globe Valve

Check Valve

Pressure Reducing Valve

w/Fast Fill Bypass

Expansion Tank

with Air Scoop and

Auto Air Vent

3-Way Valve

Valve

Pump

LEGEND:

Boiler circuit piping must be equal to or larger than

boiler water connection size.

Boiler circulation pump sized for flow through

boiler.

Dotted devices indicate alternate locations.

WARNING: This drawing shows suggested

piping configuration and valving. Check with

local codes and ordinances for additional

requirements.

Purge

Valve

3-Way Valve No. 1

Change-Over

(Heating and Cooling)

3-Way Valve No. 2

To By-Pass

Both Heater and

Chiller

To

System

From

System

By-Pass

To Boiler

and

Chiller

From

Boiler

Valve Motors

2-Pos

3-Wire - 24V

115/24V

Transformer

DPDT Manual or Automatic

Change-Over Switch

DPDT - Set at Change-Over

Temperature

Clock Timer

Auto-Resetting

Set at 15 Minute SPDT

Suggested Wiring Diagram For

Tempering System Water at

Changeover From Heating To Cooling

Figure 8. Boiler-Chiller Installation.

From

Chiller

3.2.4 Combined Space Heating/Potable

Water Heating Systems

When using the Laars boiler as a source of heat

for a combined space heating/potable water heating

system, be sure to follow the instructions of the space

heating system.