LAARS Mighty Therm LO-NOx PW (Sizes 500-1825) - Install and Operating Manual User Manual

Page 3

Mighty Therm Lo-NOx

Page 3

SECTION 1.

General Information

1.1 Introduction

This manual provides information for the

installation and operation of Laars gas-fired hydronic

boilers and water heaters. It is strongly recommended

that all application and installation procedures be

reviewed completely before proceeding with the

installation. Consult the Laars factory, or local factory

representative with any problems or questions

regarding this equipment. Experience has shown that

most problems are caused by improper installation,

not system design.

Some accessory items are shipped in separate

packages. Verify receipt of all items listed on the

package slip. Inspect everything for possible damage

upon delivery, and inform the carrier of any shortages

or impairments. Any such claims should be filed with

the carrier. The carrier, not the shipper, is responsible

for shortages and damage to the shipment whether

visible or concealed.

IMPORTANT WARNING

The Laars heaters must be installed in

accordance with the procedures outlined in this

manual. The warranty does not apply to boilers not

installed or operated in accordance with these

procedures. Consult local building and safety codes

before proceeding with work. The installation must

conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to

the latest edition of the National Fuel Gas Code;

ANSI Z223.1, National Electrical Code ANSI/NFPA

70 and/ or in Canada CAN 1 -13149 requirements.

When required by the authority having

jurisdiction, the installation must conform to

American Society of Mechanical Engineers safety

codes for controls and safety devices for automatically

fired boilers No. CSD-1, and in Canada CGA 3.3. Any

modification to the boiler, its gas controls, gas

orifices, wiring or draft diverter may void the Laars

warranty. If field conditions require such

modifications, consult factory.

1.2 Heater Identification

Consult rating plate on the boiler. The following

example simplifies the boiler identification.

1

2

3

4

5

6

PH

1200

I

N

21

K

(1) Basic heater model (see descriptions below).

(2) Input rate x 1000 BTU/h.

(3) Indoor (I) or Outdoor (E) installation.

(4) Gas type: Natural (N).

(5) Ignition system: (21) Hot surface (proved igniter)

ignition system.

(6) Firing modes:

On/Off (C)

2-stage (K)

Model PH hydronic heating boilers come with

integrally mount pumps. Pumps are sized for pressure

drop through the heat exchanger only.

Model PW water heaters for use with separate

storage tank come with integrally mount pumps.

Pumps are sized for pressure drop through the heat

exchanger plus 30 feet (9.1m) of pipes and normal

fitting.

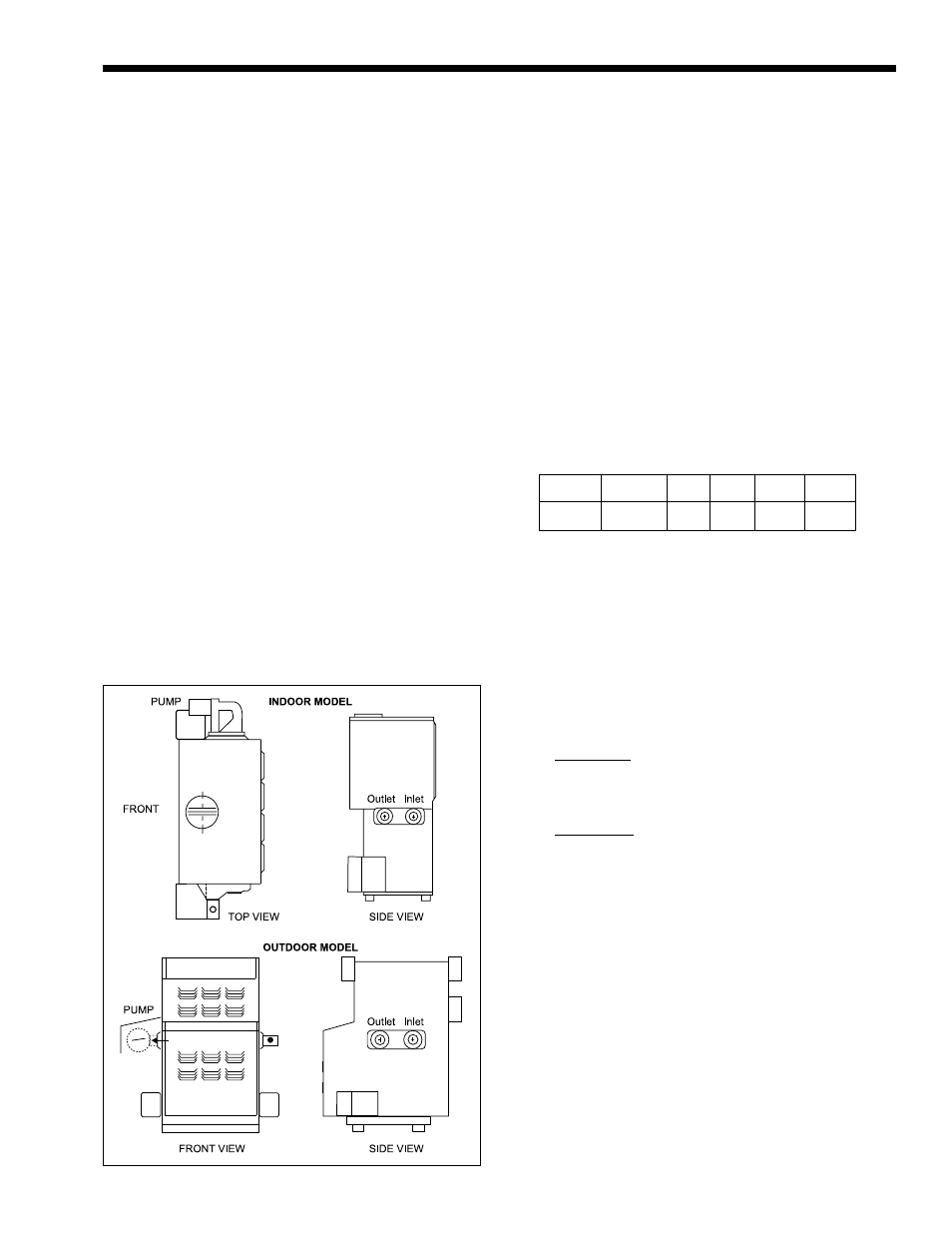

Laars heaters are available in two

configurations: an indoor version and an outdoor

version. Both are available from the factory (see

Figure 1).

1.3 General Water Flow Requirement

For proper operation, all low volume hot water

heaters must have continuous flow through the heat

exchanger when firing. The system pump must be

capable of developing sufficient pressure to overcome

the resistance of the heater plus the entire circulating

system at the designed flow rate.

Figure 1. Boiler Configuration.