LAARS Mighty Therm LO-NOx PW (Sizes 500-1825) - Install and Operating Manual User Manual

Page 13

Mighty Therm Lo-NOx

Page 13

2.

Model PW heater is not suitable for heating

swimming pools or any other application where

temperature of the water flowing through the

heater remains below the dew point (110°F).

In applications requiring the rapid use of

measured volumes of water, the recovery of the

heater between the time intervals of use must

equal the volume used. See the recovery table in

the current Document 2129 (Submittal Data).

3.

Pump Sizing: the heater circulating pump is

sized to provide enough flow to prevent damage

to the heat exchanger. Specifications in Table 4

include allowance for 30 feet of piping and 6

elbows between heater and tank.

IMPORTANT: Check oil level in pump before

starting. Oil pump every three (3) months. Fill

bearing assembly to lower level of overflow

vent. Add five (5) or six (6) drops of oil to front

and rear of motor. Use 20W non-detergent oil.

Pumps located in excessively hot or dusty

locations should be oiled once a month. Self

lubricating pumps do not require oiling.

4.

The pump should be accessible for lubrication,

inspection and service.

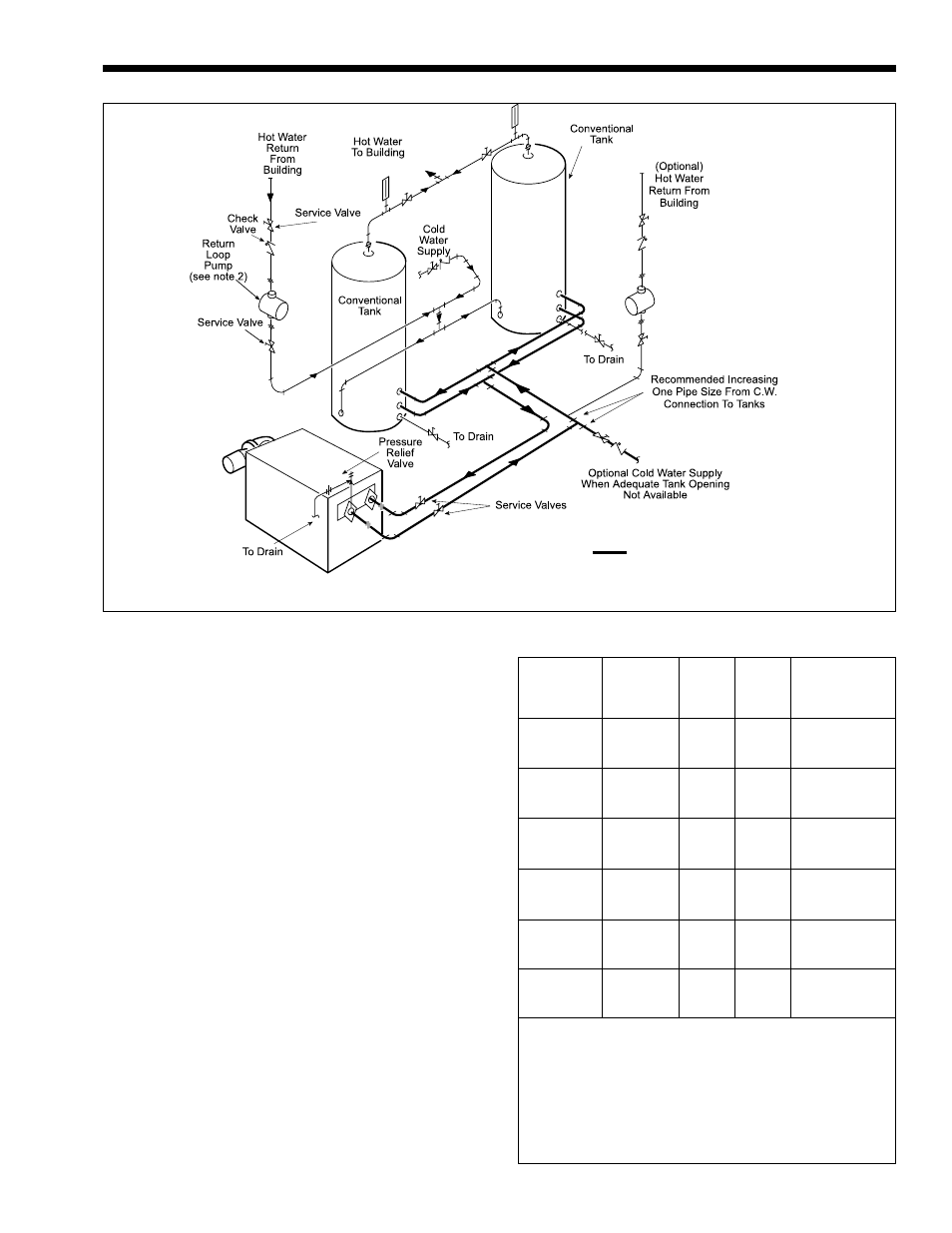

Figure 14. Hot Water Supply System Using Dual Tanks.

NOTES:

1. Heavy line

indicates Heater to Tank Circulating Loop.

2. When a very large volume of water is circulated in the building

loop with the use of a separate pump, tee building loop into cold

water supply and return to storage tank.

Flow Head* Temp. Rise

Water Rate Loss Across

Model Category (GPM) (ft.) Heater, (°F)

Soft

45

5.0

17

500

Normal

68

9.9

11

Hard

90

15.7

8

Soft

45

5.3

24

715

Normal

68

11.0

16

Hard

90

17.8

12

999

Soft

45

3.9

35

and

Normal

68

7.5

23

1010

Hard

90

11.7

18

Soft

68

7.8

27

1200

Normal

68

7.8

27

Hard

90

12.2

21

Soft**

68

8.1

32

1430

Normal

68

8.1

32

Hard

90

12.6

24

Soft**

90

13.5

30

1825

Normal**

90

13.5

30

Hard

90

13.5

30

Water Category Grain Hardness per Gal.

Soft

1 through 7.5

Normal 7.6 through 17

Hard

Over 17

* Pressure drop includes loss through 30 feet of pipe and normal fittings when

heater is installed with storage tank. Pipe and fittings are assumed to be 2" on

Models (500-715) and 2 1/2" on Models (1010-1825)

** To prevent erosion, these models must be ordered with cupro-nickel heat

exchanger tubes.

Table 4. Pump Performance Requirements.