1 heater placement, 2 installation of indoor heaters – LAARS Mighty Therm LO-NOx PW (Sizes 500-1825) - Install and Operating Manual User Manual

Page 4

LAARS HEATING SYSTEMS

Page 4

SECTION 2.

Installation

2.1 Heater Placement

The heater must be placed to provide specific

clearances on all sides for maintenance and

inspections. There must also be minimum distances

maintained from combustible surfaces. These

clearances also apply to noncombustible materials

because the heater requires air circulation for proper

operation.

The heater should be mounted on a level surface.

An integral base for an installation on combustible

flooring is provided as standard equipment on all

models.

Do not install a heater on carpeting.

Under the national Fuel Gas Code, ANSI

Z223.1, it is permissible to place the heater on floors

other than noncombustible when the installation

complies with the American Insurance Code. Figures

2, 3, and 4 show common installation on combustible

flooring.

2.2 Installation of Indoor Heaters

Locate the heater to provide adequate clearance

for inspection and service on all sides. See Table 1.

Install indoor heaters on a waterproof floor with

an adequate floor drain and a 6" (152mm) minimum

curb on all four sides to protect the building if heater

repairs are required. The manufacturer will not be

held liable for any water damage in connection

with this heater.

2.2.1 Combustion Air Supply

The heater location must provide sufficient air

supply for proper combustion and ventilation of the

surrounding area as outlined in the latest edition of

ANSI standard Z223.1, and any local codes that may

be applicable. Inadequate combustion air supply may

result in incomplete combustion, sooting of the heat

exchanger, and unsafe operation of the boiler.

2.2.1.a Conventional Ventilation

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1: Two permanent openings, one

commencing within 12 inches (300 mm) of the top

and one commencing within 12 inches (300 mm) of

the bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts, with

the outdoors or spaces that freely communicate with

the outdoors.. When directly communicating with the

outdoors, or when communicating to the outdoors

through vertical ducts, each opening shall have a

minimum free area of 1 square inch per 4000 BTU/h

(550 square mm/kW) of the total input rating of all

equipment in the enclosure. When communicating to

the outdoors through horizontal ducts, each opening

shall have a minimum free area of not less than 1

square inch per 2000 BTU/h (1100 square mm/Kw) of

the total input rating of all equipment in the enclosure.

Clearance

Indoor

Outdoor

from

in.

mm

in.

mm

Top

30

762

unobstructed

Water Conn. side

12*

305

24

610

Pump side

6*

152

24

610

Front

Alcove*

unobstructed

Rear

8

203

24

610

Vent pipe**

6

152

- - -

Hot water pipes

per code

per code

* Water connection and pump side clearances of 24" (610mm)

and front clearances of 48" (1219mm) will allow easier

service access.

** One inch using type B vent (refer to Manufacturer's Instructions).

Table 1. Minimum Heater Clearances From

Adjacent Surfaces.

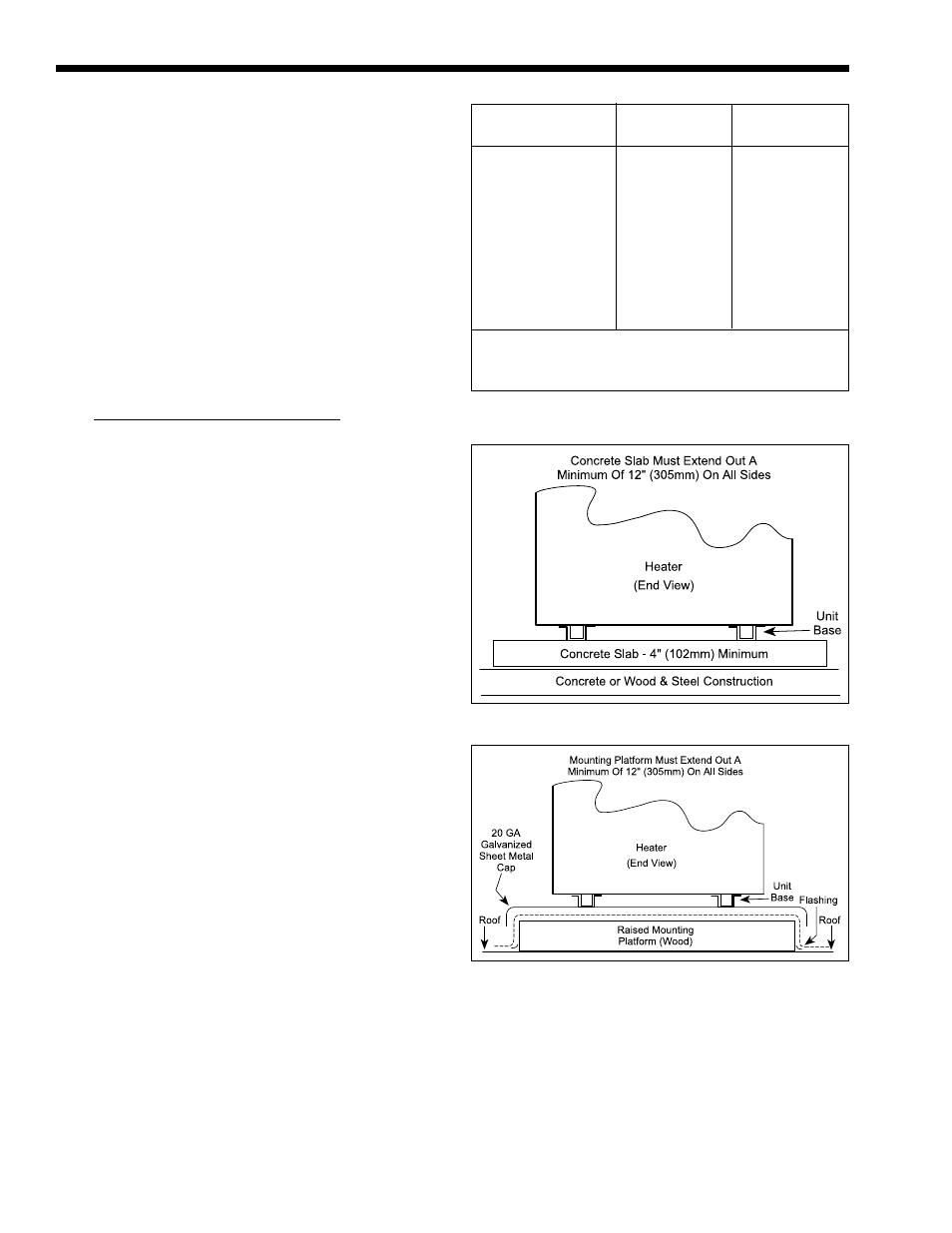

Figure 2. Typical Heater Installation on Concrete Slab.

Figure 3. Typical Heater Installation on Roof Using

Raised Platform (wood).