LAARS Mighty Therm LO-NOx PW (Sizes 500-1825) - Install and Operating Manual User Manual

Page 14

LAARS HEATING SYSTEMS

Page 14

3.3.5 Water Pressure

It is very important that water pressure in the

system be maintained above 30 psi. If the system

pressure should drop below this, the vapor pressure of

water in the suction side of the pump can cause

hammer and cavitation in the pump and damage the

heater through lack of water circulation.

For protection against excessive pressure the

water heater is equipped with a pressure relief valve.

When the water heater is connected to a separate

storage vessel, a temperature and pressure relief valve

must be installed on the storage vessel. The

temperature and pressure relief valve must be design-

certified in accordance with the requirements for

Relief Valves and Automatic Gas Shutoff Devices for

Hot Water Supply Systems, ANSI Z21.22. (in Canada,

in accordance with the requirements for the Standard

for Temperature and Pressure Relief Valves and

Vacuum Relief Valves, CAN1-4.4).

The temperature and pressure relief valve must

have a BTU/h (kW/h) capacity rating that is greater

than the BTU/h (kW/h) input of the water heater. The

temperature and pressure relief valve must be marked

with a maximum working pressure not to exceed the

maximum working pressure shown on the rating plate

of the water heater, or the maximum working pressure

of the separate storage vessel, whichever is the lower

pressure. The temperature and pressure relief valve

must have a maximum working temperature not to

exceed 210°F (99°C).

Do not place any shutoff valves between the

temperature and pressure relief valve and the storage

vessel.

The relief valves discharge water in large

quantities should circumstances demand.

3.3.6 Tank Installation

1.

Be sure the floor is waterproof and structurally

capable of supporting the tank when it is filled

with water.

2.

The tank should be placed so that manholes,

inspection covers, nameplates and drain valves

are accessible.

3.

Be sure the tank is suitable for the water in the

system. Some water is corrosive and requires a

protected tank with a special lining.

4.

If the tank is glass-lined, it should be equipped

with a suitable magnesium anode. It is good

practice to replace the anode when it is

approximately 50% used. The factory warranty

on a glass-lined tank, if provided, will be void if

a satisfactory anode is not in place at the time of

a failure or if it is consumed by cathodic action.

5.

Make sure the tank connections in the heater-

tank circulating loop are the proper size as listed

in Section 3.3.4. If tappings are smaller than the

recommended pipe size, a larger pump may be

required. Consult the factory if in doubt.

6.

Install a pipe in the tank drain fitting that goes to

a floor sink, and install a drain valve. If a floor

sink is not available, install a hose bib.

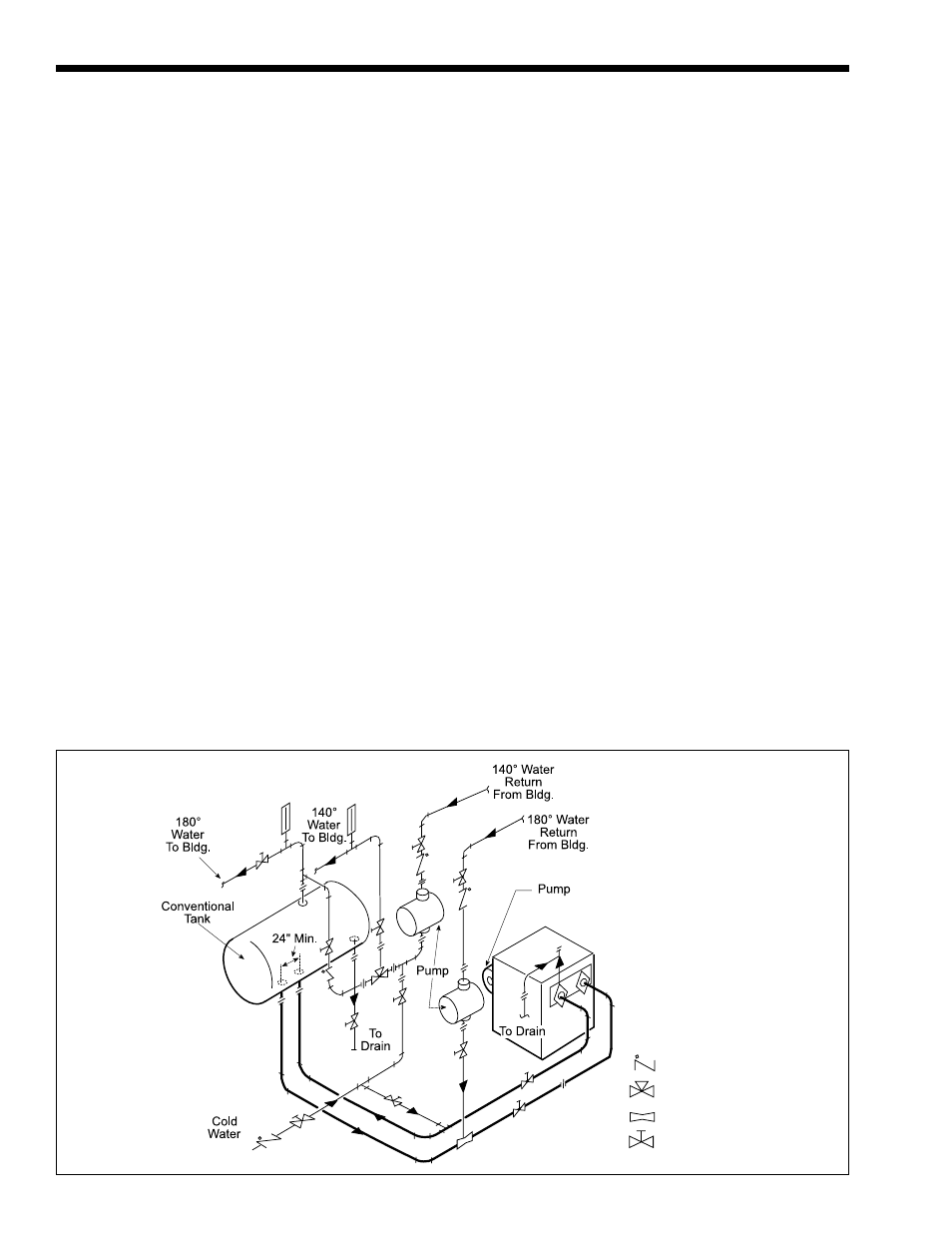

3.3.7 Two-Temperature System

See Figures 15 and 16 for piping schematics.

This system is designed to maintain the tempered

water circulating loop at the desired temperature

Legend

Check Valve

Tempering Valve

Venturi (Suction) Tee

Throttling Valves / Service Valves

Figure 15. Two Temperature Hot Water Supply system with Horizontal Tank.