LAARS MAX 165 (DV) - Installation, Operation and Maintenance Instructions User Manual

Page 3

MAX Oil-Fired Boiler

Page 3

SECTION 1.

General Information

1A. Introduction

The MAX Boiler has been constructed to meet

the stringent requirements of the ASME Boiler Codes

and designed to provide a rapid response to hot water

and heating demands at a very high thermal efficiency.

This is a low mass boiler. To take advantage of

this feature, and prevent short cycling, always select

the lowest firing rate satisfactory for the load

requirement.

The boiler is supplied either for connection to a

conventional chimney or comes complete with a

balanced flue system for direct venting through the

wall.

With the balanced flue system, air for

combustion is drawn from outside through a terminal

and ducted directly to the burner, making the boiler

virtually room sealed. Flue gases are discharged

through the same terminal so that wind pressures are

applied equally to inlet and outlet, making it a true

balanced flue system. A silencer is also incorporated

in the terminal to reduce the flue gas discharge noise.

This is a particularly useful feature if the terminal is

located near a bedroom window or adjacent to

neighboring properties.

The boiler is constructed with two concentric

water jackets, the inner one forming the furnace tube

and the outer the flue gas annulus. Flue gas retarders

fitted around the annulus are specifically designed to

extract the maximum heat from the gases with

minimum pressure loss.

The simple annular design also makes it possible

to keep the water content to a minimum (only 3.2 gals.

[12L] for the MAX (DV) 75, 100, 120 and 5.1 gals.

[19L] for the MAX (DV) 140, 165). Because of this

low mass, water is rapidly heated to the temperature

demands. Another benefit of the low thermal mass is

the insignificant level of standby loss when the burner

shuts down.

To achieve the best possible heat transfer, the

boiler is designed on the “Series Flow” principle

whereby the return water is preheated by first passing

through the outer water annulus before coming into

contact with the furnace tube. This arrangement also

provides a counter flow of flue gases and water so that

the coolest gases come into contact with the coolest

water for the most efficient heat transfer.

Heavily insulated doors at front and back of

boiler, provide easy access for cleaning and

inspection, with the burner being swung on the front

door either left or right as required.

Accurate sensing of temperature and pressure is

assured by grouping all controls and safety devices on

a common supply manifold.

The use of the latest flame retention head burner

allows the boiler to operate under a slight positive

pressure which ensures stable combustion under

virtually all operating conditions.

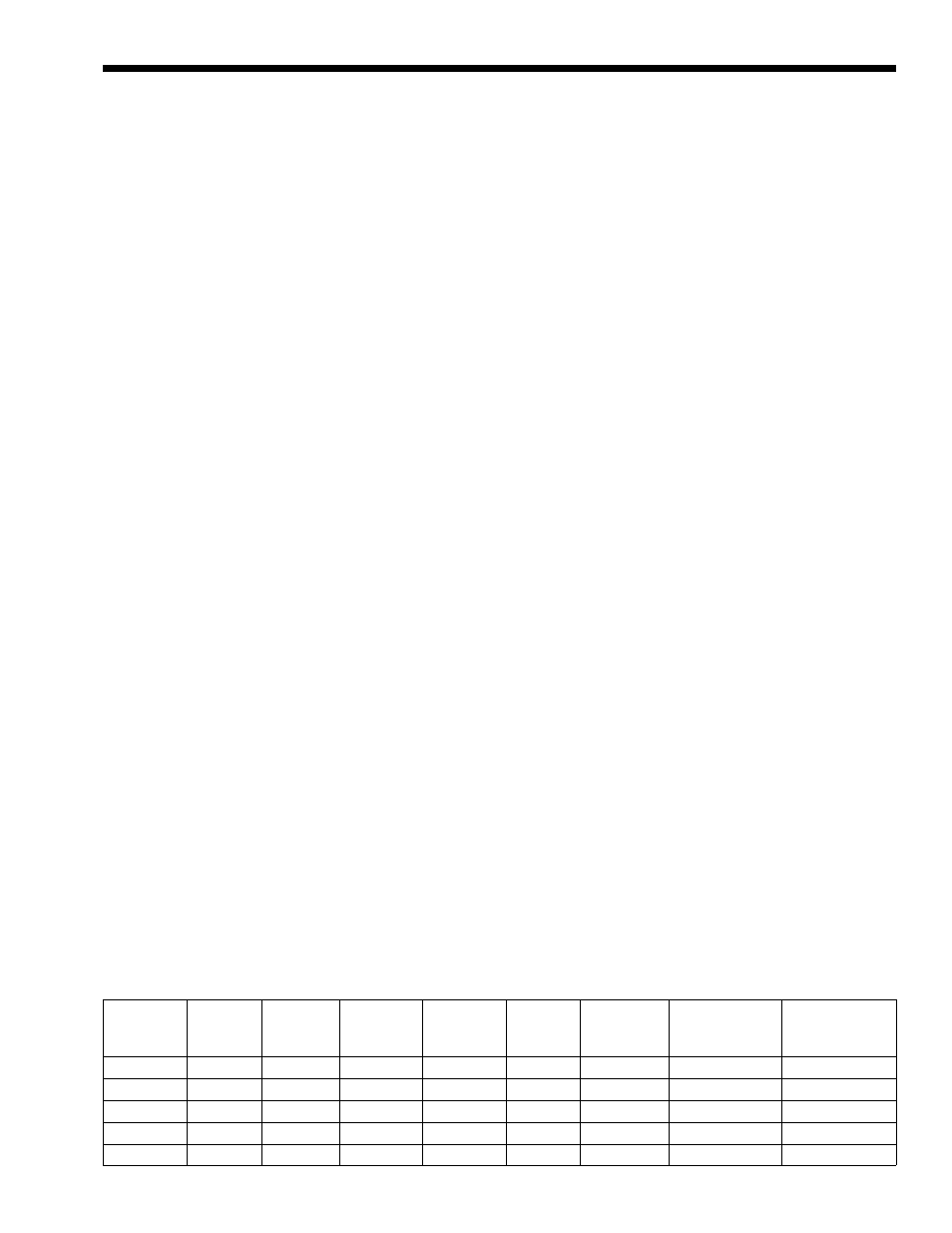

MAX (DV)

GPH

Nozzle

Pump

Input

AFUE

Heating

Water

Shipping

Model

Rate

Size

Pressure

MBTH/hr

Rating

Capacity

Content

Weight

GPH

P.S.I.

%

BTU/h

gal.

L

lbs.

kg

75

0.72

0.65

140

101

87.0

85,900

3.0

12

324

147

100

1.00

0.85

140

140

86.5

121,200

3.2

12

324

147

120

1.20

1.00

140

168

86.0

141,600

3.2

12

324

147

140

1.40

1.20

150

196

85.6

166,000

5.1

19

431

196

165

1.65

1.35

150

231

85.0

192,400

5.1

19

431

196

Table 1. Boiler Specifications.