LAARS MAX 165 (DV) - Installation, Operation and Maintenance Instructions User Manual

Page 21

MAX Oil-Fired Boiler

Page 21

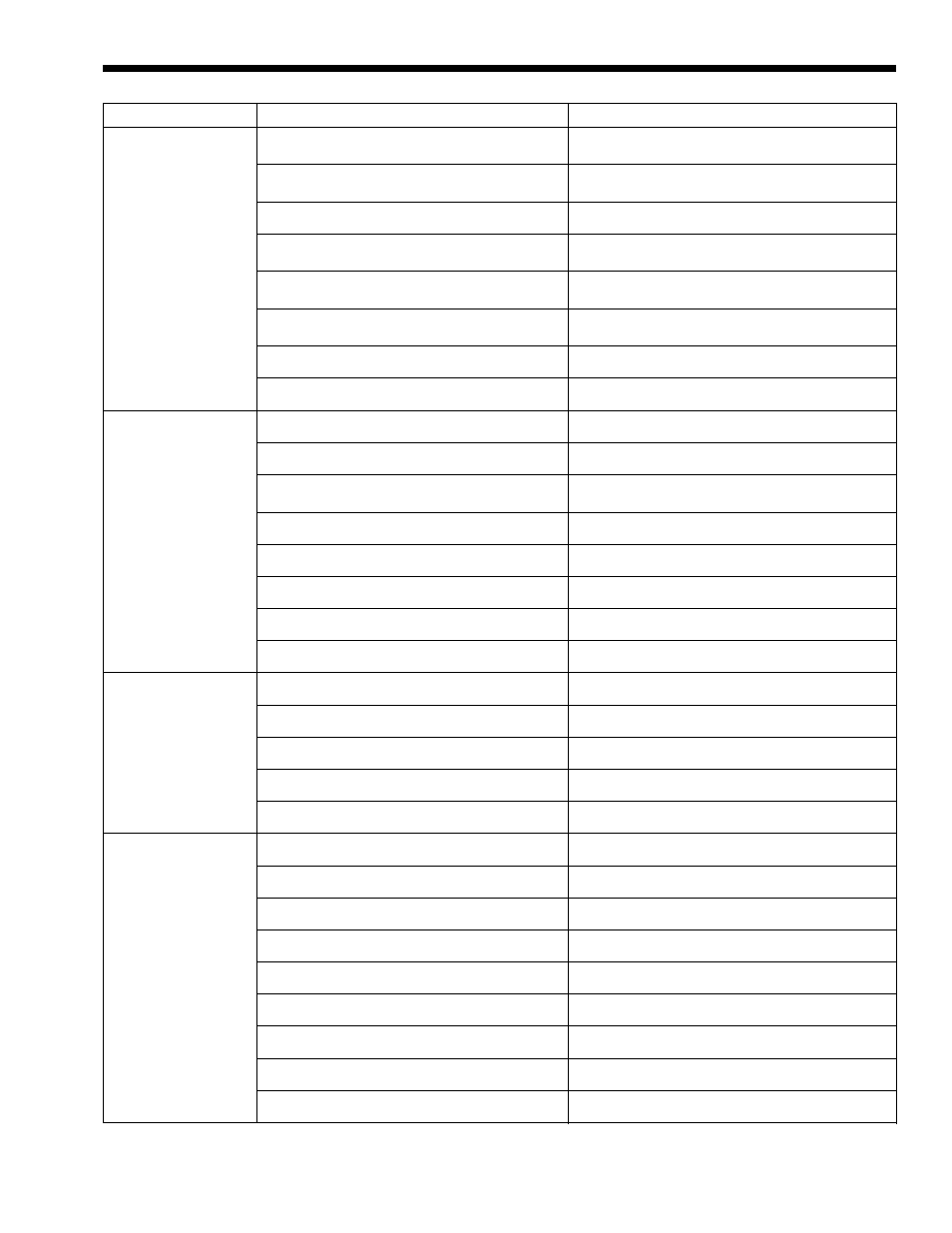

Table 4. Troubleshooting.

FAULT

BURNER

DOES NOT

START

BURNER RUNS

BUT FLAME NOT

ESTABLISHED

FLAME

ESTABLISHED

THEN BURNER

LOCKS OUT

BURNER

PULSATES

POSSIBLE CAUSE

ACTION

Primary safety control tripped

Press reset button on control.

Note: ONLY PRESS ONCE.

High limit thermostat or blocked vent switch

Press reset button on both controls.

tripped (MAX only)

Thermostat satisfied

Turn thermostat to a higher setting.

Fuse blown or breaker tripped

Fit new fuse or reset breaker. If it blows again,

check for short circuit.

Check voltage at burner between orange

If voltage confirmed replace primary control.

and white wires

If no voltage check t-stat and wiring connects.

Motor or fuel pump seized

Turn off power to burner and rotate by hand.

Replace if necessary.

Cad. cell dirty or faulty

Clean face or replace cell.

No oil supply

Check oil level in tank and oil supply to burner.

Water in oil tank

Drain water from tank and bleed line to burner.

Nozzle plugged

Replace with nozzle specified in manual.

Ignition transformer faulty

Check quality of spark and replace transformer

if necessary.

Electrodes carboned or shorting

Clean electrode and check settings.

MAX-DV blocked vent or air intake

Clear debris from around vent terminal.

Faulty oil valve

Replace valve.

Too much combustion air

Reduce air setting to obtain 11 to 12% CO

2

.

Low oil pressure

Check pump pressure and adjust to 140 psi.

Water in oil tank

Drain water from tank and bleed line to burner.

Oil filter or pump strainer plugged

Replace filter cartridge and clean strainer.

Too much or too little combustion air

Adjust air control to obtain 11 to 12% CO

2

.

Air trapped in fuel pump

Bleed off air from pressure gauge port.

Low oil pressure

Check pump pressure and adjust to 140 psi.

Lack of combustion air

Check terminal for block at air intake screens.

Terminal fouled with debris at flue gas outlet

Remove end cap and clean outlet.

Incorrect air setting

Adjust air control to obtain 11 to 12% CO

2

.

Air leakage into fuel system

Bleed pump and seal air leaks.

Water in oil tank

Drain water from tank oil at burner.

Incorrect pump pressure

Check oil pressure and adjust to 140 psi.

Pump coupling worn or broken

Replace coupling.

Nozzle partially pluggeD

Replace with nozzle specified in manual.

Boiler flue ways fouled

Brush out all flue deposits.