3 unpacking the appliance, 4 locating the appliance, 5 clearances – LAARS EDN Series - Installation, Operation and Maintenance Instructions User Manual

Page 4: Laars heating systems company

Page 4

LAARS Heating Systems Company

Options Code

X = None

Revision

2 = Second

Revision

b. The Canadian Electrical Code (CSA C22.1),

latest edition.

c. All applicable local installation codes must also

be adhered to.

All vent installations must be made in accordance

with:

a. The applicable venting requirements of the

National Fuel Gas Code (ANSI Z223.1/NFPA

54), latest edition; or

b. in Canada, The Natural Gas and Propane

Installation Code (CSA B149.1), latest edition.

All applicable provisions of local building codes

should also be adhered to.

1.3 Unpacking the Appliance

Remove all packing and tie down materials.

Make immediate claims (to the carrier) if the appliance

and its packaging are damaged.

1.4 Locating the Appliance

The appliance is designed for installation on

combustible flooring, in alcoves, basements, closets,

or utility rooms. It must NOT be installed on

carpeting. IF INSTALLED IN A FINISHED AREA,

PROVISION SHOULD BE MADE FOR DRAINAGE

OF ANY ACCIDENTAL SPILLAGE OR LEAKAGE.

The location for the unit should be chosen with

regard to venting dimensions, convenient access to

piping, and accessibility for service and cleaning.

The boiler shall be installed so that the gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation or service (circulator replacement, control

replacement, etc.).

1.5 Clearances

The dimension and criteria in Table 1 should be

followed when choosing the location for the unit.

SECTION 2.

Venting Options

The Endurance boilers are certified as direct vent,

sealed combustion boilers, when vented using one of

the following two methods:

1) Concentric direct vent, which has a flue gas pipe

inside a combustion air pipe.

2) Non-concentric direct vent, using separate pipes

for the flue gases and the combustion air.

The Endurance boilers can also take air from

the space (when properly sized), and be vented as a

Category IV appliance.

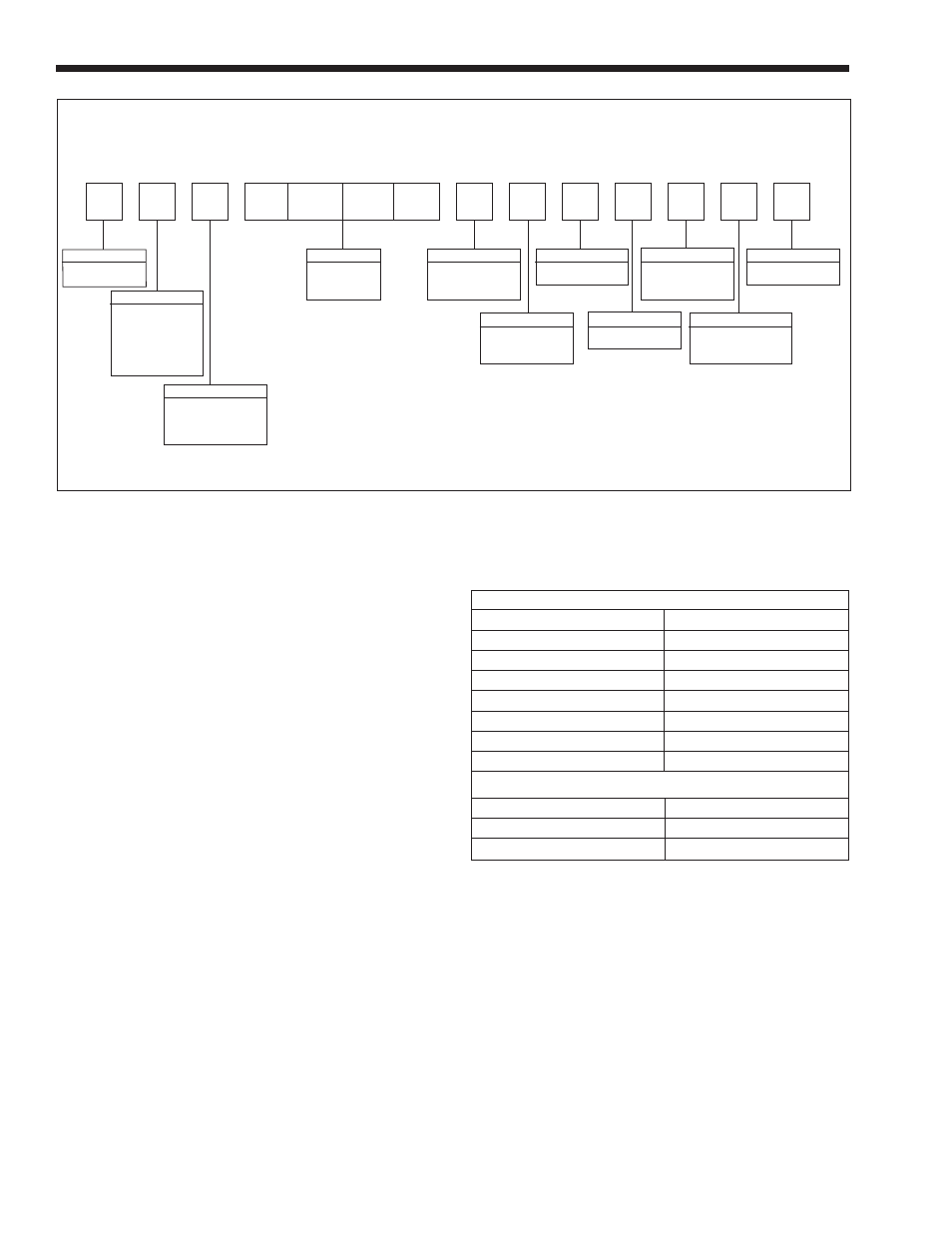

Figure 3. Model Structure.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

E

I

F

2

X

Prod. Line

E = Endurance

Usage

B = Combination,

Heating &

Domestic

Water

D = Heating Only

Type

P = Standard

N = Non Ferrous

(ED Units Only)

BTU Input

0 1 1 0

0 1 7 5

Fuel

N = Natural Gas

P = Propane

Altitude

A = 0' - 5,000'

H = Over 5,000'

Location

I = Indoor

Firing Mode

F = Modulating

Country of Sale

A = USA & Canada

R = Russia

Minimum Clearances From Combustible Materials

Back

1 inch

25mm

Left Side

1 inch

25mm

Right Side

1 inch

25mm

Front

1 inch

25mm

Top (Alcove Install)

1 inch

25mm

Top (Closet Install)*

22 inches 559mm

Vent: Concentric, Direct

0 inch

0mm

Vent: Category

3 inches 76mm

Suggested Serviceability Clearances

Front

18 inches 457mm

Left Side

6 inches 152mm

Right Side

6 inches 152mm

*Minimum closet height 6'9" 206 cm

Table 1. Clearances.