4 non-concentric combustion air, 1 gas piping – LAARS EDN Series - Installation, Operation and Maintenance Instructions User Manual

Page 12

Page 12

LAARS Heating Systems Company

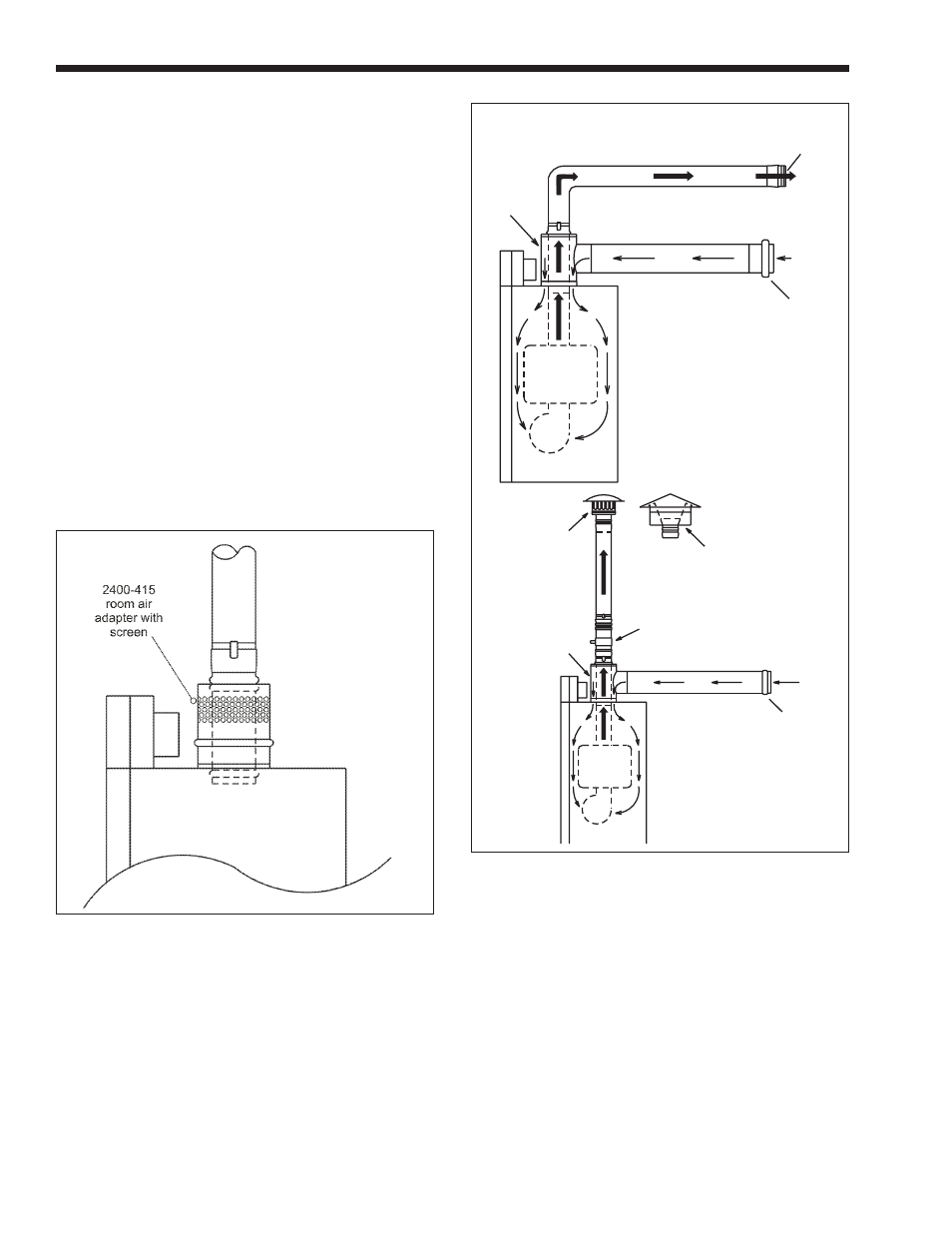

2400-435 tee

(to separate

venting from

combustion air)

4" air terminal

(field-supplied)

4" combustion air pipe

Fan

Combustion

Chamber

combustion

air

2400-409 condensate trap

(used if vent height is

greater than 7 feet)

2400-416

concentric rain cap

(use only on systems

with condensate trap)

2400-370

vertical vent cap

(can be used on system with

or without condensate trap)

2400-426

3" vent termination

with screen

2400-435 tee

(to separate

venting from

combustion

air)

4" air terminal

(field-supplied)

4" combustion air pipe

(15 equivalent feet, maximum)

3" diameter vent

(50 equivalent feet, maximum)

Fan

Combustion

Chamber

vent

gases

combustion

air

Figure 14. Combustion Air from Room.

The opening shall directly communicate with the

outdoors or shall communicate through a vertical

or horizontal duct to the outdoors or spaces that

freely communicate with the outdoors and shall

have a minimum free area of:

b1. 1 in.

2

/3000 Btu/hr (700 mm

2

/kW) of

total input rating of all equipment in the

enclosure, and

b2. Not less than the sum of the areas of all

vent connectors in the confined space.

2.3.3 Connecting Special Gas Vent to

the Appliance

When drawing combustion air from the adjacent

space, part number 2400-415 (room adapter with

screen) can be used. One portion of this assembly

connects to the 5" air collar (with a screen for the

combustion air) and the other part connects to the 3"

flue opening (see Figure 14). The rest of the 3" vent

system can be connected to the adapter within the

2400-415.

2.4 Non-Concentric Combustion Air

An alternate, non-concentric combustion air

source may be installed (as shown in Figure 15),

provided that the minimum 4" diameter combustion air

duct does not exceed 15' (4.6m). Termination should

include an air screen and be located in a qualified air

space (see Section 2.3) or outside.

Separated combustion air / flue gas may be

considered either “mechanical draft” or “direct vent”.

To be considered “direct vent”, all of the combustion

air and flue gas piping must be sealed stainless steel

special gas vent, listed to U.L. 1738 and U.L.C. 636.

When the system meets this requirement, vent terminal

clearances may be less than that of a non-direct

vent system. See Figure 8 for direct vent terminal

clearances.

The combustion air pipe may be galvanized

material, but if used, the system is a “mechanical vent”

system, and the vent terminal clearances must be per

the rules for “mechanical vent” systems. See Figure 8.

SECTION 3.

3.1 Gas Piping

The appliance requires an inlet gas pressure of

at least 4" w.c. (1.0kPa) and no greater than 13" WC

Non-Concentric Direct Vent with

Horizontal Vent.

Non-Concentric Direct Vent with

Vertical Vent.

Figure 15. Non-Concentric Combustion Air.