LAARS EDN Series - Installation, Operation and Maintenance Instructions User Manual

Page 16

Page 16

LAARS Heating Systems Company

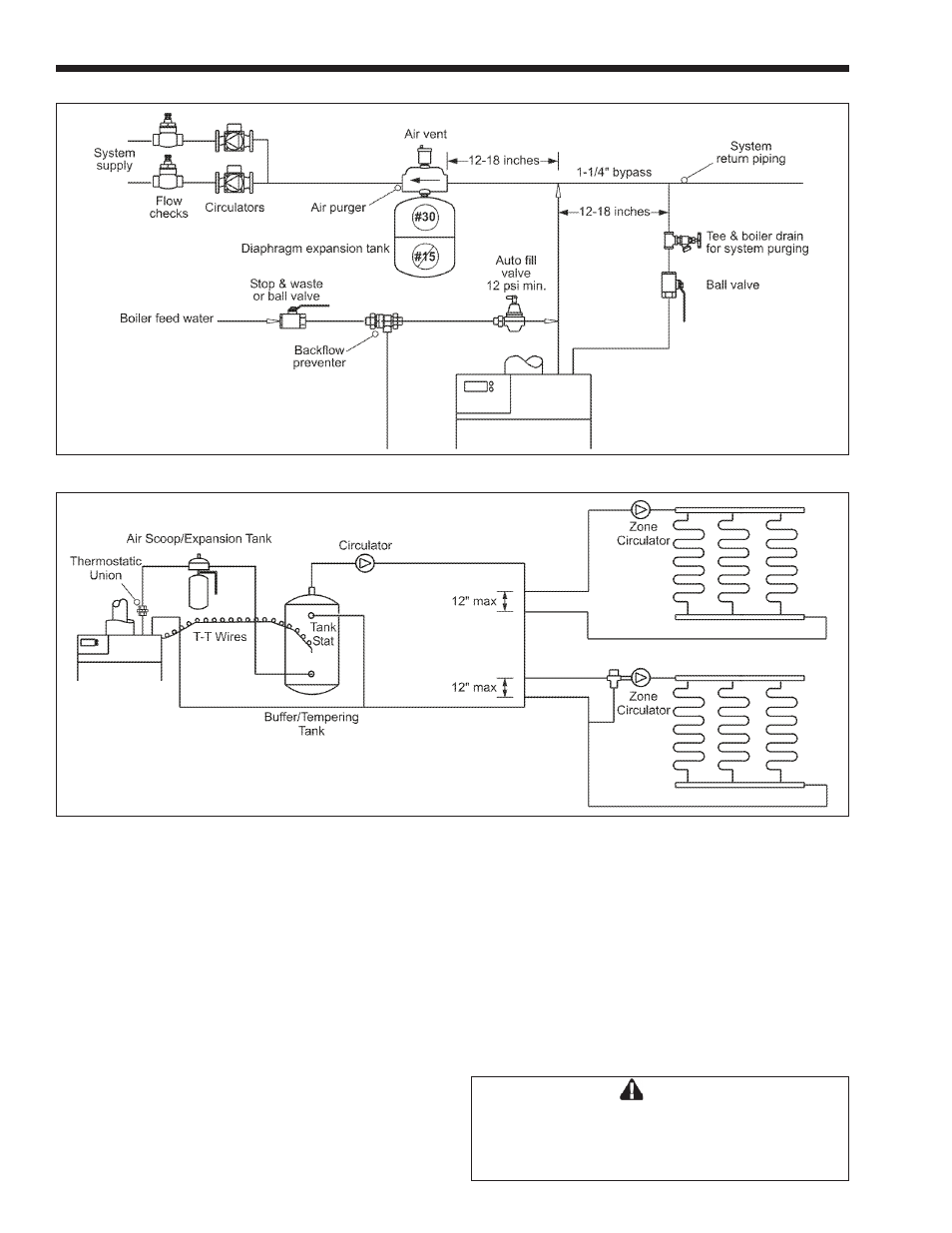

EDP/EDN boilers installed in radiant (in floor)

systems and other low mass boilers should be provided

with a buffer/blender tank to assure a controlled supply

temperature, and to prevent short cycling. In radiant

systems utilizing 3-way tempering valves, a bypass

pipe must be installed between supply and return piping.

1. EBP ONLY: Connect system supply to 1¼"

supply connection marked “SUPPLY”.

2. EDP/EDN ONLY: Connect 1¼" thermostatic

union to system supply connection in direction

designated with union.

3. Pipe the discharge of the relief valve, full size,

to a drain or in a manner to prevent injury in the

event of pressure relief.

4. Install an air purger in flow supply line as shown

in piping diagrams.

5. Install automatic float type air vent on air scoops.

Figure 22. Hydronic Piping EBP/EDP for Systems Zoned with Circulators.

Figure 23. Hydronic Piping EDP for Low-Temp and/or Multi-Temp Systems.

6. Install a diaphragm expansion tank in boiler

outlet piping. To ensure sufficient expansion

volume for the hydronic system water, due to

heat-up and cool-down during normal operation,

a #30 or larger expansion tank must be used on

EBP combo units.

NOTE: Never install expansion tank and auto fill

valve on return.

7. If necessary, install a properly sized circulator

with optional isolation valves in supply beyond

expansion tank.

Caution

To avoid the risk of fire which can result in property

damage, all hot water pipes must be installed with

a minimum 1" (25mm) clearance from combustible

materials.