LAARS U.H.E. - Installation Manual User Manual

Page 8

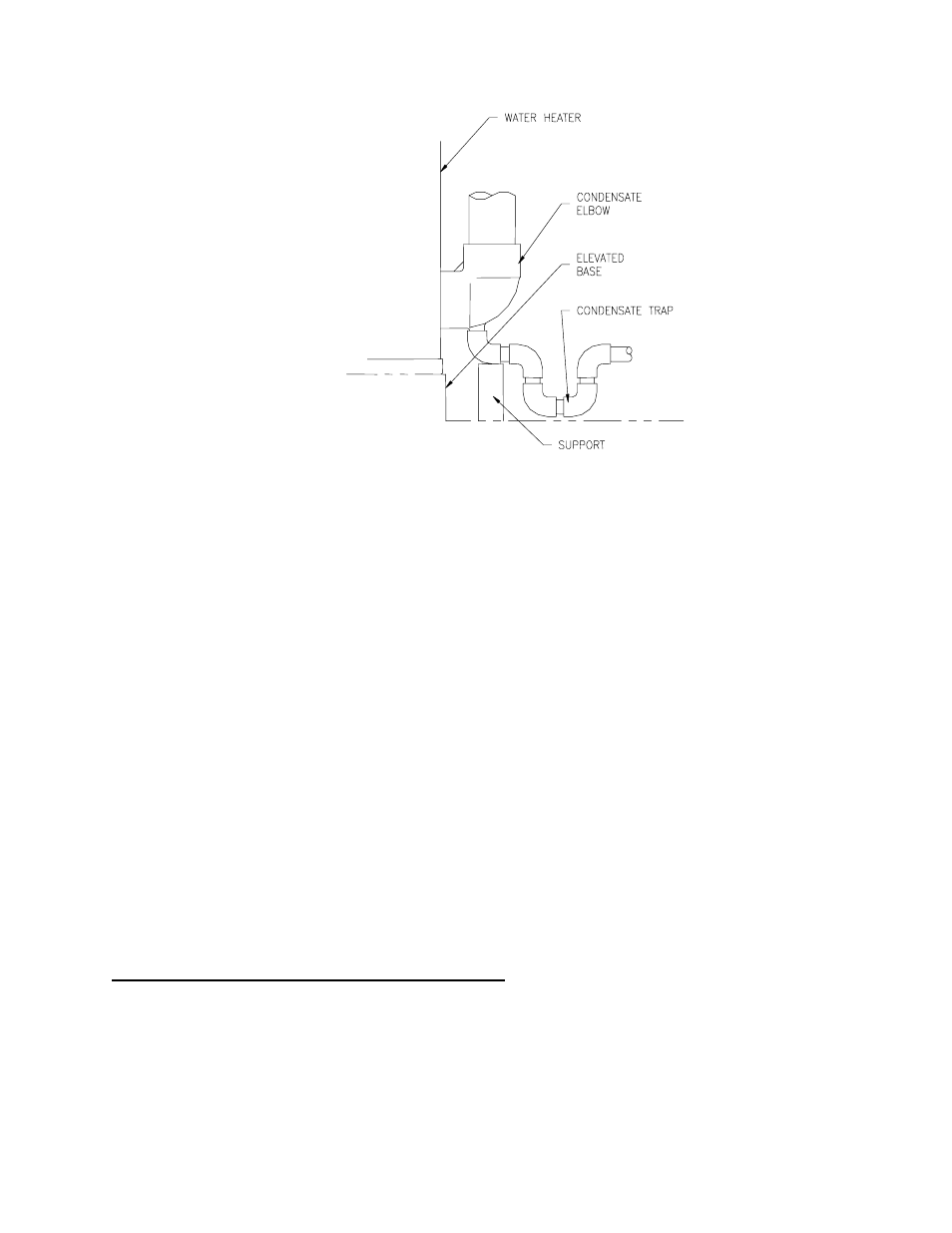

Figure 2. Condensate Elbow With Trap

CLEANOUT – All models are equipped with a cleanout opening to aid in removal of hard water deposits from the

tank bottom. If this water heater operates under hard water conditions, the following should be performed at least every

3 months: Turn off water supply and drain the water heater. Remove the cleanout jacket cover and tank cover. When

cleaning the tank, care must be taken to avoid trying to break deposits loose as this could damage the glass lining and

shorten the life of the water heater. After cleaning, re-install the cleanout tank cover and jacket cover, and refill with

water. Refer to the section, “Section X – Maintenance” in this Installation and Operating Instruction manual for the

procedures for filling and draining the water heater.

SACRIFICIAL ANODES – Four sacrificial anode rods have been installed in the tank head to extend tank life. The

anode rods should be inspected periodically for corrosion and replaced when necessary to prolong tank life. Water

conditions in your area will influence the time interval for inspection and replacement of the anode rods. The use of a

water softener may increase the speed of anode consumption. More frequent inspection of the anodes is needed when

using softened (or phosphate treated) water. Contact the installing contractor, or service provider that installed the

water heater or the manufacturer listed on the rating plate for anode replacement information.

POWERED ANODE SYSTEM (399,999 BTU/HR. MODELS ONLY) – Two powered anodes and one magnesium

anode rod are used on models with input ratings of 399,999 Btu/hr. The powered anode system provides corrosion

protection to the tank by supplying a low voltage current to the titanium anode rods and then periodically comparing

this current with the potential between the anode rod and tank wall to make corrections. The powered anode system is

designed to extend the tank life without requiring anode rod replacement. The powered anode system consists of two

titanium powered anode rods located in the front top of the water heater tank and a powered anode control module

located on the right side of the control panel. More details on the powered anode system are in “Section X –

Maintenance” in this Installation and Operating Instruction Manual.

DISHWASHING MACHINE REQUIREMENTS

All dishwashing machines meeting the National Sanitation Foundation requirements are designed to operate with water

flow pressures between 15 and 25 pounds per square inch. Flow pressures above 25 pounds per square inch, or below

15 pounds per square inch, will result in improperly sanitized dishes.

The National Sanitation Foundation also recommends circulation of 180°F water. Where this is done, the circulation

should be very gentle so that it does not cause any unnecessary turbulence inside the water heater. The circulation

should be just enough to provide 180°F water at the point of take-off to the dishwashing machine. Adjust flow by

means of the valve in the circulation line.

8