Notice – LAARS U.H.E. - Installation Manual User Manual

Page 24

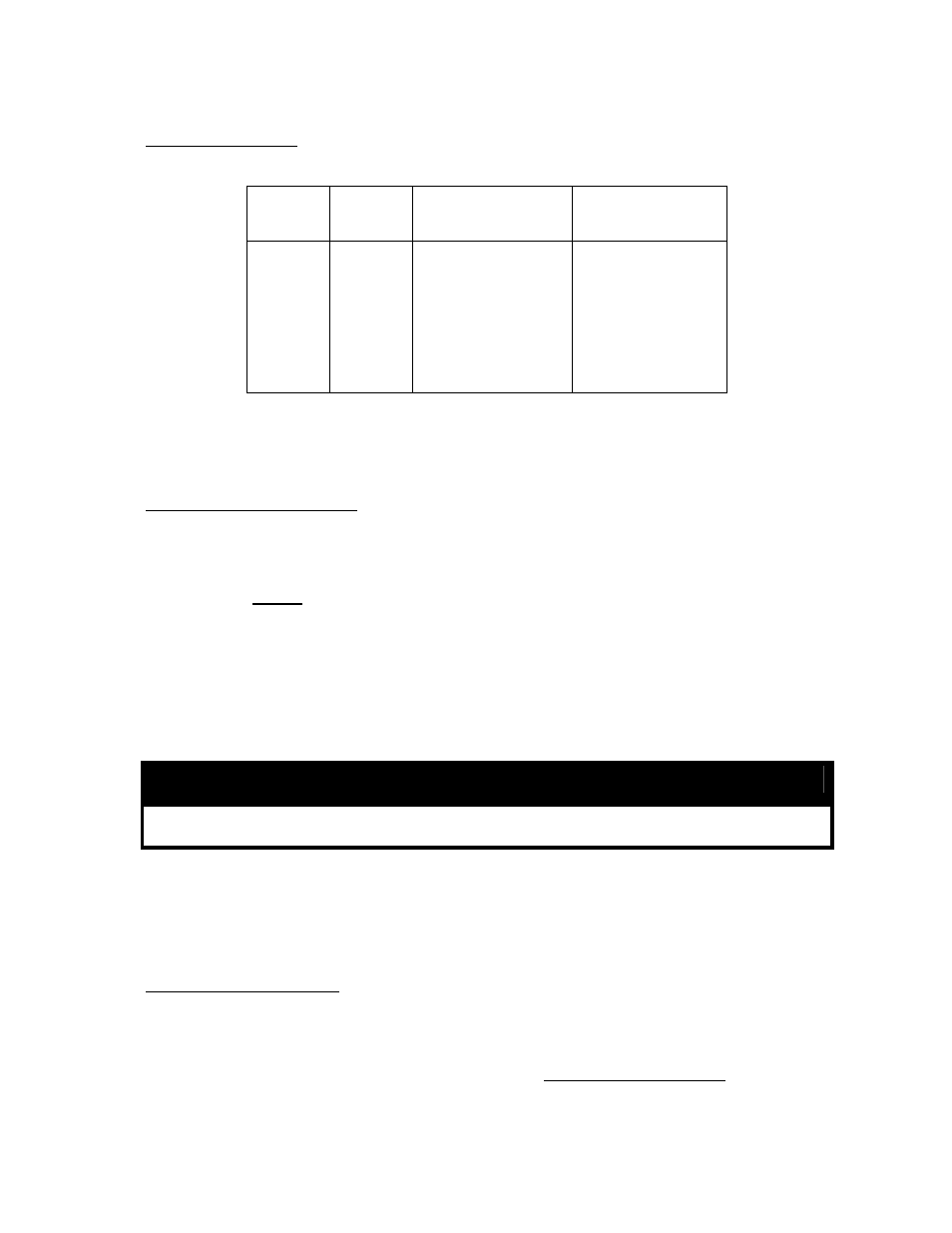

Maximum Vent Length:

Direct Vent Maximum Vent Length (Combined Maximum Length for Intake and Exhaust)

Storage

Capacity

(Gallons)

Rated Input

(BTU/HR)

Max Vent Length (feet)

3" PVC, CPVC, or ABS

Max Vent Length (feet)

4" PVC, CPVC, or ABS

60 125,000

120

170

60 150,000

100

150

60

100

100

100

100

100

199,000

150,000

199,999

250,000

300,000

399,999

80

120

100

80

60

50

130

170

150

130

110

100

Table 3

Note: The venting distance shown in the chart above is the combined maximum distance for

the intake and exhaust pipe and elbows.

Determining required vent length:

1. Determine the total length of straight vent pipe (in feet) required for both the intake and the exhaust.

2. Add 5 feet of venting for every 90° elbow.

3. Add 2 ½ feet of venting for every 45° elbow.

4. Total vent length cannot exceed “Max Vent Length” in Table 3.

5. Air intake cannot exceed exhaust by more than 30 feet in any venting situation.

Example of Total Direct Vent Length for 100 gallon 199,999 btuh model:

A 3” venting system has a total of six 90-degree elbows and a total straight pipe length of 65 feet

(includes both intake and exhaust pipe).

Equivalent vent length for elbows: 6 x 5 feet = 30 feet.

Total equivalvent vent distance = 65 feet + 30 feet = 95 feet total equivalent vent length. This is

below the maximum allowed distance of 100 feet for this model using 3” vent.

NOTICE

Do not include the 3” condensate elbow or vent terminals in determining maximum vent

length

.

POWER VENT INSTALLATION

Power venting is where the indoor air is used and the exhaust is vented to the outside. Venting may be run horizontally

through an outside wall or vertically through a roof through using either 3 inch (7.6 cm) or 4-inch (10.2 cm) diameter

PVC, ABS or CPVC. This water heater is supplied with a screened intake and exhaust 90° elbow referred to as the

exhaust vent terminal and the air intake terminal.

Power Vent Terminal Location

Refer to the “Direct Vent Terminal Location” section previously mention to determine the proper exhaust vent

location. Plan the vent system layout so that proper clearances are maintained from plumbing and wiring.

Vent pipes serving power vented appliances are classified by building codes as “vent connectors”. Required

clearances from combustible materials must be provided in accordance with information in this manual under

LOCATION OF WATER HEATER, and CLEARANCES, and with National Fuel Gas Code and local codes.

24