LAARS Mighty Therm2 MT2P (Sizes 500–2000 MBTU/h) - Install and Operating Manual User Manual

Page 6

LAARS Heating Systems

Page 6

SECTION 2.

Venting and Combustion Air

2.1 Combustion Air

MT2P pool heaters must have provisions for

combustion and ventilation air in accordance with

Section 5.3, Air for Combustion and Ventilation, of the

National Fuel Gas Code, ANSI Z223.1, or Sections 7.2,

7.3 or 7.4 of CAN/CGA B149, Installation Codes, or

applicable provisions of the local building codes.

A MT2P appliance may receive combustion air

from the space in which it is installed, or it can be

ducted directly to the unit from the outside. Ventilation

air must be provided in either case. Never obtain

combustion air from the pool area. Corrosion of and/or

damage to the pool heater may result.

2.1.1 Combustion Air From Room

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1: Two permanent openings, one

commencing within 12 inches (30 cm) of the top

and one commencing within 12 inches (30 cm) of

the bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts,

with the outdoors or spaces that freely communicate

with the outdoors. When directly communicating

with the outdoors, or when communicating to the

outdoors through vertical ducts, each opening shall

have a minimum free area of 1 square inch per 4000

Btu/hr (5.5 square cm/kW) of total input rating of

all equipment in the enclosure (

see Table 3

). When

communicating to the outdoors through horizontal

ducts, each opening shall have a minimum free area of

not less than 1 square inch per 2000 Btu/hr (11 square

cm/kW) of total input rating of all equipment in the

enclosure.

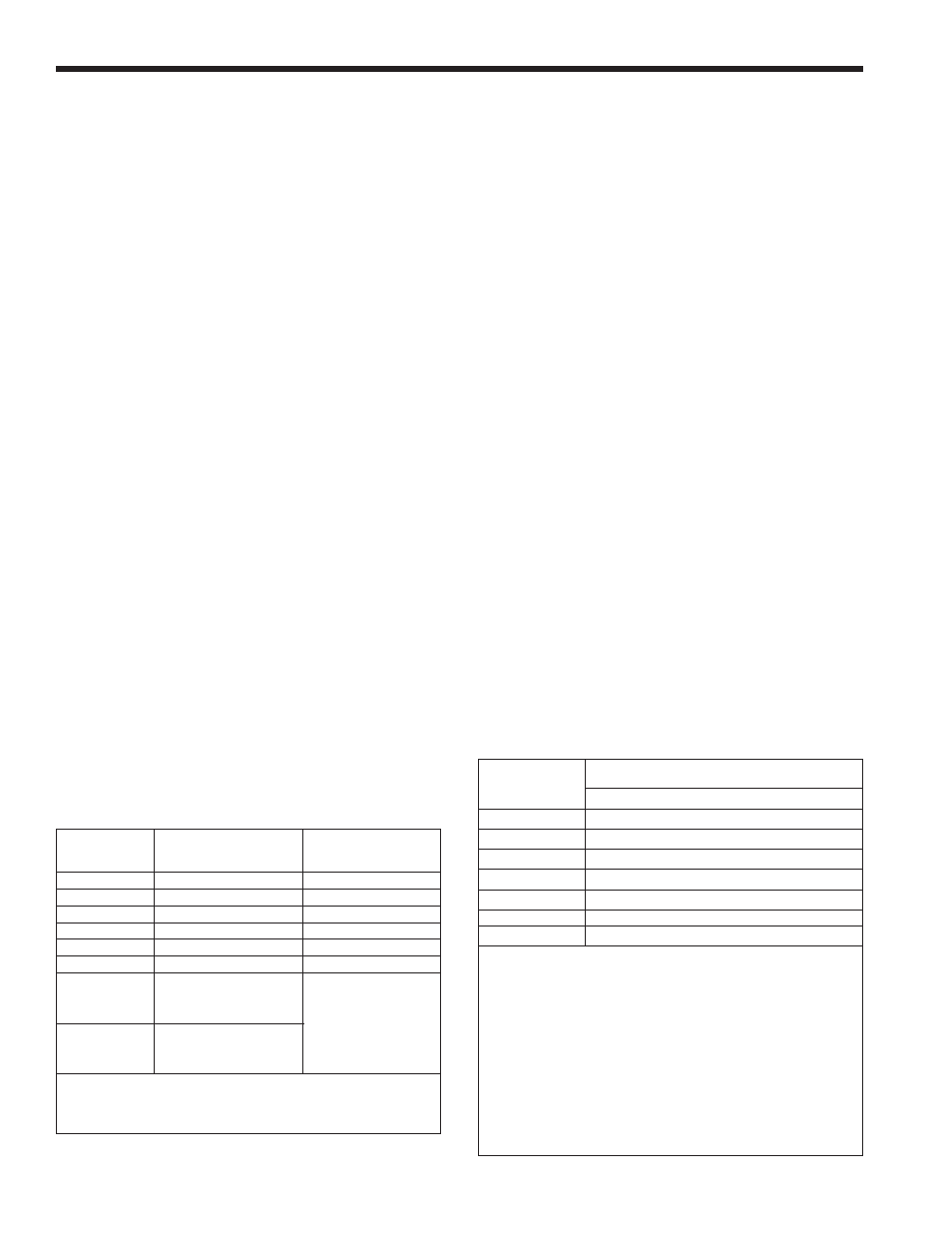

Table 3

shows data for this sizing method,

for each MT2P model.

Method 2: One permanent opening, commencing

within 12 inches (30 cm) of the top of the enclosure,

shall be permitted. The opening shall directly

communicate with the outdoors or shall communicate

through a vertical or horizontal duct to the outdoors or

spaces that directly communicate with the outdoors and

shall have a minimum free area of 1 square inch per

3000 Btu/hr (7 square cm/kW) of the total input rating

of all equipment located in the enclosure. This opening

must not be less than the sum of the areas of all vent

connectors in the confined space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in the applicable codes listed above.

In Canada, consult local building and safety codes

or, in absence of such requirements, follow CAN/CGA

B149.

2.1.2 Intake Combustion Air

Never obtain combustion air from the pool area.

Corrosion of and/or damage to the pool heater may

result. The combustion air can be taken through the

wall, or through the roof. When taken from the wall, it

must be taken from out-of-doors by means of the Laars

horizontal wall terminal (

see Table 1

). When taken

from the roof, a field-supplied rain cap or an elbow

arrangement must be used to prevent entry of rain water

(

see Figure 2

).

Use single-wall galvanized pipe (

per Table

EACH OPENING*

SIZE

Square inches

Square cm

500

125

807

750

188

1213

1000

250

1613

1250

313

2020

1500

375

2420

1750

438

2826

2000

500

3226

*Net Free Area in Square Inches / Square cm

Area indicated is for one of two openings; one at floor level

and one at the ceiling, so the total net free area could be

double the figures indicated.

This chart is for use when communicating directly with the

outdoors. For special conditions and alternate methods,

refer to the latest edition of ANSI Z223.1.

Note: Check with louver manufacturers for net free area of

louvers. Correct for screen resistance to the net free area

if a screen is installed. Check all local codes applicable to

combustion air.

Table 3. Combustion Air Openings.

REqUIRED

RECOMMENDED

APPLIANCE

CLEARANCE FROM

SERVICE ACCESS

SURFACE

COMBUSTIBLE MATERIAL

CLEARANCE

inches

cm inches

cm

Left Side

1

2.5 24

61

Right Side

1

2.5 24

61

Top

1 2.5 12 30

Back

1

2.5

**

12**

30**

Front

1

2.5 36

91

Vertical

(Category 1)

6*

15.2*

Vent

Horizontal

per UL1738 venting

(Category 3)

system supplier’s

Vent

instructions

*1" (2.5cm) when b-vent is used.

**When vent and/or combustion air connects to the back,

recommended clearance is 36" (91cm).

Table 2. Clearances.