2 temperature (operating) control, 3 limit controls, Laars heating systems – LAARS Mighty Therm2 MT2P (Sizes 500–2000 MBTU/h) - Install and Operating Manual User Manual

Page 14: Page 14

LAARS Heating Systems

Page 14

35 67

T'stat

35 67

T'stat

35 67

T'stat

35 67

T'stat

AQUASTAT

STAGE 1

STAGE 1

SWITCH

SELECT

PUMP

L1

TB1-1

HEATER

HIGH

LIMIT

POLE 6

POLE 5

TERMINAL

BLOCK 1

BD #2

IGN

BD #1

IGN

IGN

BD #2

IGN

IGN

BD #1

IGN

BD #1

IGN

BD #2

IGN

BD #2

IGN

BD #1

IGN

LIGHT

10

GAS

HIGH

GAS

8

2

PUMP

IGN

BD #1

IGN

BD #2

IGN BD #2

BD #1

IGN

DRY CONTACT

ALARM

ALARM

SILENCE

BELL

IGN BD #2

L.O.

L.O.(G)

L.O.

BD #1

IGN

L.O.(G)

1

P2

P1

1

2

Delay on Break

Relay

Initiate

9

stage 2

stage 1

Gas Valve

Gas Valve

IGN

BD #1

IGN

BD #2

6

Press

35 67

Press

35 67

#2

of Fan

Proof

of Fan

#1

4

3

Interlock

Field

Gas

35 67

Gas

35 67

IGN

BD #2

IGN

BD #1

IGN

BD #1

BD #2

IGN

24V

35 67

24V

35 67

GND

35 67

GND

35 67

BLOCK

POOL

SUPPY

HIGH

LIMIT

LOW

24 VAC

120 VAC

BLOWER 2

BLOWER 1

LOW

HIGH

LOW

HIGH

K1

K2

K1

K2

F2

35 67

F2

35 67

F1

35 67

F1

35 67

K3

HSI #2

HSI #1

120 VAC

DPDT

MAIN

POWER

SWITCH

S2

S2

35 67

35 67

L2

35 67

L2

35 67

BD #1

IGN

S1

S1

35 67

35 67

35 67

L1

35 67

JUMPER

N1

FLOW

SWITCH

5

SWITCH

SELECT

PUMP

L1

TB1-1

POLE 6

POLE 5

TERMINAL

BLOCK 1

BD #2

IGN

BD #1

IGN

BD #1

IGN

BD #2

IGN

BD #2

IGN

BD #1

IGN

BD #1

IGN

BD #2

IGN

BD #2

IGN

BD #1

IGN

LIGHT

FLUE

PUMP

IGN

BD #1

IGN

BD #2

DRY CONTACT

ALARM

R

LIGHT

ALARM

SILENCE

BELL

35 67

35 67

35 67

35 67

1

P2

P1

1

2

K2

K1

Delay on Break

Relay

Initiate

K3

9

7

stage 2

stage 1

Gas Valve

Gas Valve

IGN

BD #1

IGN

BD #2

6

Press

35 67

Press

35 67

#2

of Fan

Proof

Proof

4

3

Interlock

Field

Gas

35 67

Gas

35 67

IGN

BD #2

IGN

BD #1

IGN

BD #1

BD #2

IGN

24V

35 67

24V

35 67

GND

35 67

GND

35 67

24 VAC

120 VAC

BLOWER 2

BLOWER 1

LOW

HIGH

LOW

HIGH

K1

K2

K1

K2

F2

35 67

F2

35 67

F1

35 67

F1

35 67

K3

HSI #2

HSI #1

120 VAC

DPDT

MAIN

POWER

SWITCH

S2

S2

35 67

35 67

L2

35 67

L2

35 67

BD #2

IGN

BD #1

IGN

S1

S1

35 67

35 67

35 67

L1

35 67

JUMPER

N1

L1

STAGE 2

24V

C

H2331200E

5.1.1 Changing Single Circuit to Two

Circuits

Sizes 500 to 1500 will be shipped from the factory

for a single 120-volt power supply. To use a separate

circuit for the pump:

1. Ensure power is disabled to the unit

2. Remove the three jumper wires that connect

the L2, N2 and GROUND wires on terminal

block 1 to the main distribution terminal block.

These wires will be black/white, white and green

respectively.

5.1.2 Field Wiring

Field wiring connection points are located inside

the line voltage connection/field wire area. Single

120-volt units will be field connected at the main

terminal block labeled "120V (L1)", "NEUTRAL" and

"GROUND" (see

Figure 6

for over-current protection

ratings).

Sizes 1750-2000, and those which have been field

retrofitted to electrically separate the pump and heater,

require two 120-volt circuits. The heater circuit is found

on the main terminal block and denoted as "120V (L1)",

"NEUTRAL" and "GROUND". The pump circuit is

located on terminal block 1 and is denoted as "120V

(L2)", "N2 (PUMP MTD)", "GROUND 2 (PUMP

MTD)" (see

Figure 6

for over-current protection

ratings).

5.2 Temperature (Operating) Control

The MT2P temperature control operates by

measuring the pool loop return temperature, before

the heater inlet piping. It is adjustable to a maximum

of 105° F and will prevent heater operation at return

temperatures above 105° F. It also contributes to the

temperature of the water entering the heat exchanger.

The automatic mixing system is already installed,

shown in

Figure 4.

During operation, the automatic

mixing system diverts water from the outlet to the inlet

to “pre warm” the water to a minimum inlet temp -

erature of about 120°F. This prevents condensation

from forming, which can damage the heater.

Caution

Should overheating occur or the gas supply fail to

shut off, turn off the manual gas control valve to the

appliance.

5.3 Limit Controls

In addition to the pool heater temperature control,

MT2P appliances are fitted with a Pool Loop high limit

set at 135°F and an automatic reset heater high limit

with a maximum setting of 200°F.

The Pool Loop high-limit sensing bulb is to be

installed in the sensor well (supplied), downstream of

the heater (

see Figure 5

). If sufficient capillary length

exists to reach the sensor location, the control may

remain in its location near the rear of the cabinet on

the right side, behind the slide out drawer. If the sensor

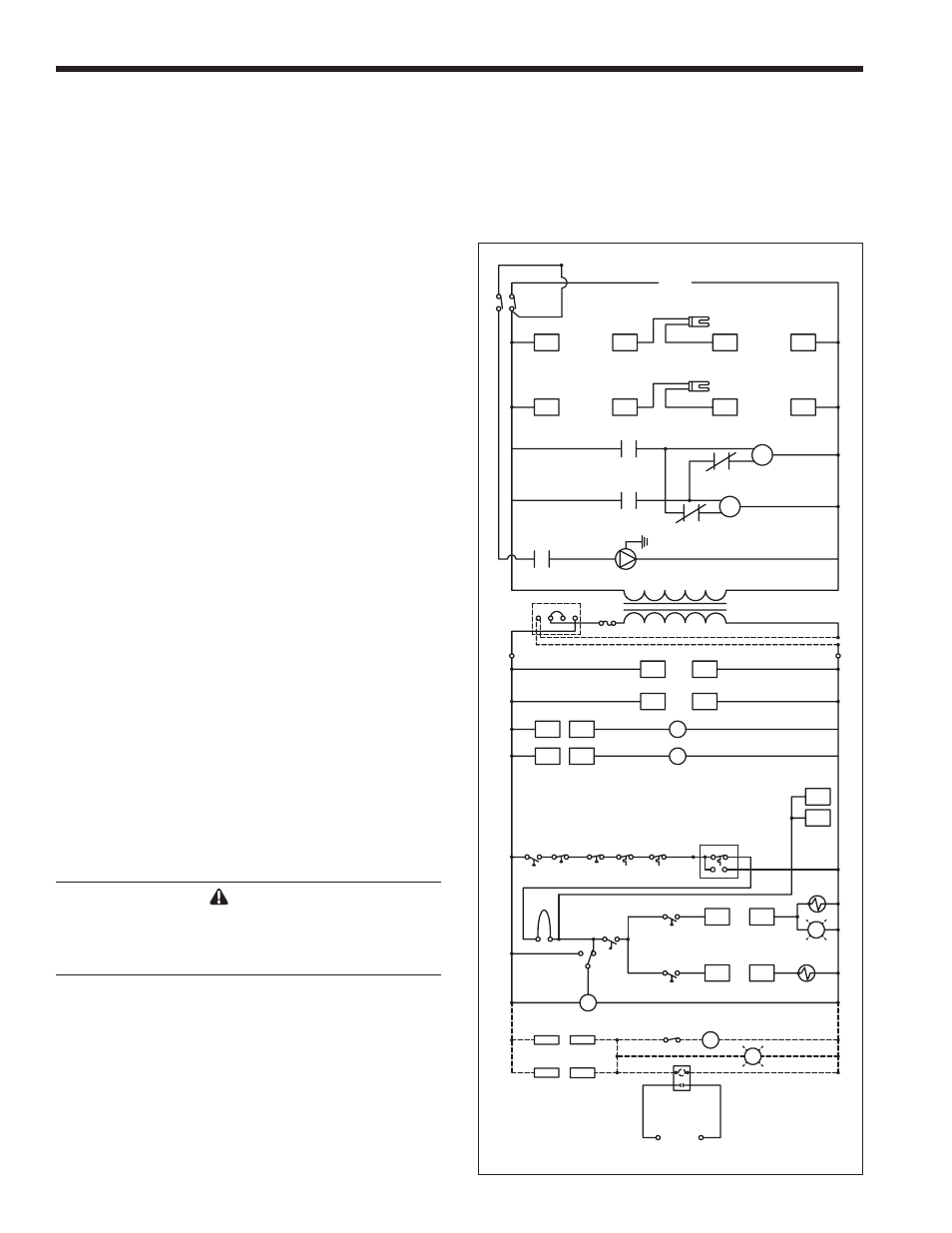

Figure 9. Wiring Schematic, sizes 1250-2000.

location is farther from the heater than the capillary

will reach to, then the control should be moved to the

remote location and the wires extended to the new

location of the control. If the controller needs to be

moved, and it is being moved to an outdoor location,

the control will need to be put in a weather-tight

enclosure to protect it from rain, snow, etc.