LAARS Mighty Therm2 MT2P (Sizes 500–2000 MBTU/h) - Install and Operating Manual User Manual

Page 4

LAARS Heating Systems

Page 4

14 Heat Exchanger

B = Glass-lined cast iron / copper / bronze trim

(std. on water heaters)

C = Glass-lined cast iron / copper

(std. on boilers, n/a on water heaters)

N = Glass-lined cast iron / cupro-nickel

(n/a on water heaters)

P = Glass-lined cast iron / cu-nickel / bronze trim

15 Option Code

X = Standard unit

J = CSD-1, FM, IRI, IL

16 Pump Options

N = Pump mounted, TACO, normal water pump

B = Pump mounted, B&G, optional normal water pump

1.3 Warranty

Laars Heating Systems appliances are covered

by a limited warranty. Owners should submit online

warranty registration at

www.Laars.com

.

All warranty claims must be made to an authorized

Laars Heating Systems representative, directly to

Customer Service, or online at

www.Laars.com

.

Claims must include the serial number and model

(this information can be found on the rating plate),

installation date, and name of the installer. Shipping

costs are not included in the warranty coverage.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on

the packing slip. Inspect everything for damage

immediately upon delivery, and advise the carrier of

any shortages or damage. Any such claims should be

filed with the carrier. The carrier, not the shipper, is

responsible for shortages and damage to the shipment

whether visible or concealed.

1.4 Dimensions

See Figure 1.

1.5 Locating the Appliance

The appliance should be located to provide

clearances on all sides for maintenance and inspection.

It should not be located in an area where leakage of any

connections will result in damage to the area adjacent to

the appliance or to lower floors of the structure.

When such a location is not available, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance.

The appliance is design certified by CSA-

International for installation on combustible flooring;

in basements; in closets, utility rooms or alcoves.

The location for the appliance should be chosen with

regard to the vent pipe lengths and external plumbing.

The unit shall be installed such that the gas ignition

system components are protected from water (dripping,

spraying, rain, etc.) during operation and service

(circulator replacement, control replacement, etc.).

When vented vertically, the MT2P must be located

as close as practical to a chimney or outside wall.

If the vent terminal and/or combustion air terminal

terminate through a wall, and there is potential for snow

accumulation in the local area, both terminals should be

installed at an appropriate level above grade.

The dimensions and requirements that are shown

in

Table 2

should be met when choosing the locations

for the appliance.

1.6 Locating Heater with Respect to Pool

System Loop

For the best results, the MT2P should be located

within 15 feet (4.6m) of the pool system loop. The

pump is sized for 30 feet (9.1m) of piping.

If the appliance must be installed with longer

piping runs, then larger diameter piping shall be used.

Consult the factory for assistance.

1.7 Locating Appliance for Correct

Horizontal Vent/Ducted Air Distance

From Outside Wall

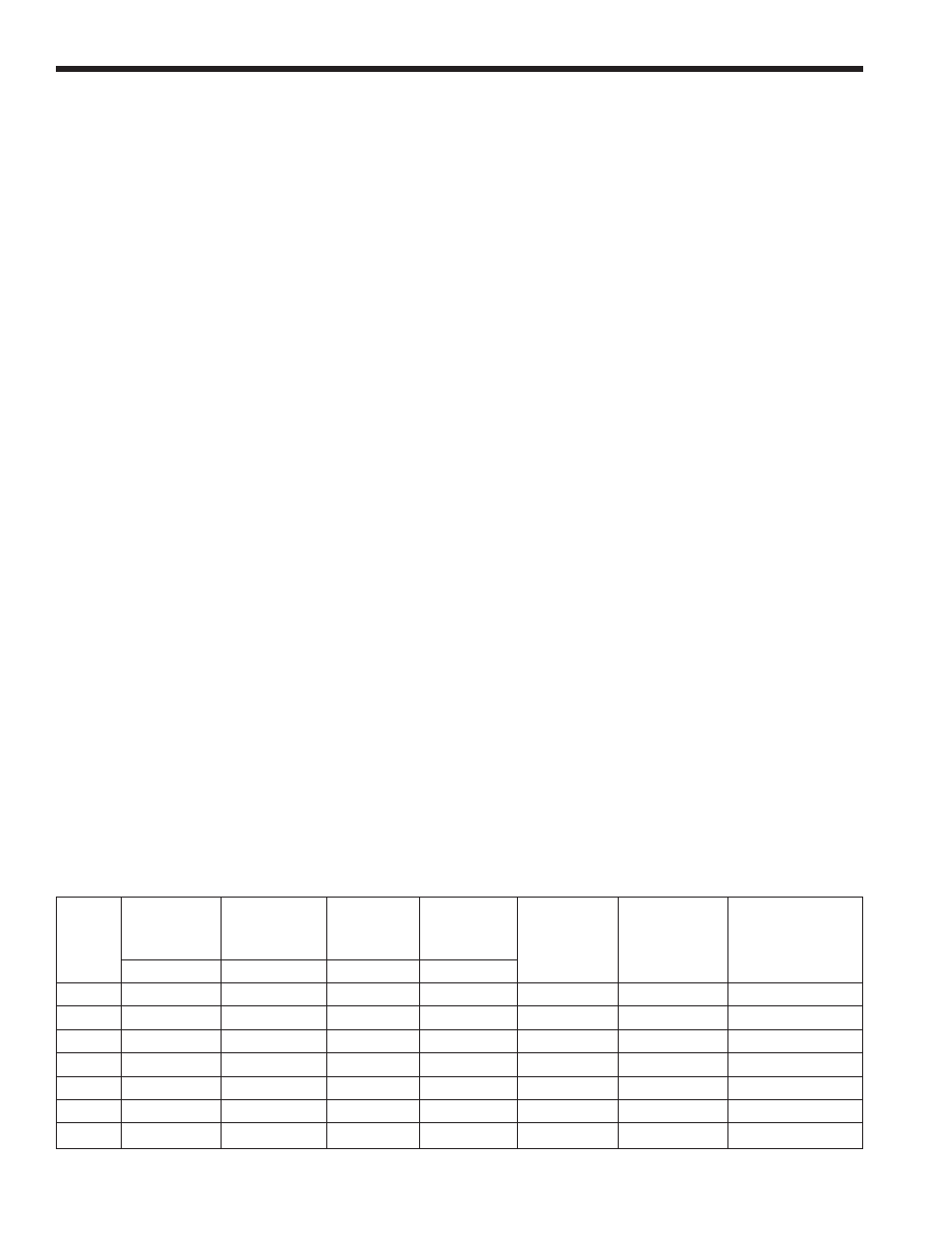

The forced draft combustion air blower/blowers

VENT

HORIZONTAL

AIR COLLAR

HEATER

COLLAR

VENT PIPE

& PIPE

MAX. PIPE

MAX. NO.

SIDE WALL

SIDE WALL

SIZE

SIZE

DIAMETER*

DIAMETER

LENGTH

OF ELBOWS

VENT

COMBUSTION

TERMINAL

AIR TERMINAL

in.

cm

in.

cm in

cm

ft. m

PART NUMBER

PART NUMBER

500

8 20 6

15 6

15 50

15

3

CA001401

20260701

750

10

25 8

20 6

15 50

15

3

CA001401

20260701

1000

10 25 8

20 8

20 50

15

3

CA001402

20260703

1250

12 30 8

20 8

20 50

15

3

CA001403

20260703

1500

12 30 8

20 8

20 50

15

3

CA001403

20260703

1750

12

30 8

20 8

20 50

15

3

CA001403

20260703

2000

14 36 12

30

12 30 50

15

3

CA001404

20260706

*Horizontal venting requires stainless vent pipe. See Table 5.

Table 1. Horizontal Vent / Combustion Air Parameters.