LAARS Mighty Therm2 MT2P (Sizes 500–2000 MBTU/h) - Install and Operating Manual User Manual

Page 10

LAARS Heating Systems

Page 10

to accommodate horizontal vent sizes, shown in

Table 1.

WARNING

The outdoor vent terminal gets hot. Unit must be

installed in such a way as to reduce the risk of burns

from contact with the vent terminal.

2.3.2 Side Wall Combustion Air Terminal

Never obtain combustion air from the pool area.

Corrosion of and/or damage to the pool heater may

result. The Laars side wall combustion air terminal

(

listed in Table 1

) must be used when the unit takes

its combustion air through a duct from a side wall.

Consider the following when installing the terminal:

1. Do not locate the air inlet terminal near a source

of corrosive chemical fumes (e.g., cleaning fluid,

chlorinated compounds, etc.)

2. Locate the terminal so that it will not be subject to

damage by accident or vandalism.

3. Locate the combustion air terminal so that it

cannot be blocked by snow. The National Fuel

Gas Code requires that it be at least 12 inches (30

cm) above grade, but the installer may determine

it should be higher, depending upon local

conditions.

4. If the MT2P is side-wall vented to the same wall,

locate the vent terminal at least 3 feet (0.9m)

horizontally from the combustion air terminal,

and locate the vent terminal at least 1 foot (0.3m)

above the combustion air terminal (see Figure 3).

2.3.3 Vertical Vent Terminal

When the unit is vented through the roof, the

vent must extend at least 3 feet (0.9m) above the point

at which it penetrates the roof. It must extend at least

2 feet (0.6m) higher than any portion of a building

within a horizontal distance of 10 feet (3.0m), and high

enough above the roof line to prevent blockage from

snow. When the combustion air is taken from the roof,

the combustion air must terminate at least 12" (30cm)

below the vent terminal (

see Figure 2

).

2.3.4 Vertical Combustion Air Terminal

When combustion air is taken from the roof, a

field-supplied rain cap or an elbow arrangement must

be used to prevent entry of rain water (

see Figure 2

).

The opening on the end of the terminal must be at least

12" (30cm) above the point at which it penetrates the

roof, and high enough above the roof line to prevent

blockage from snow. When the vent terminates on the

roof, the combustion air must terminate at least 12"

(30cm) below the vent terminal.

2.4 Vent Terminals for Outdoor Units

For outdoor applications, the vent and combustion

air openings must be covered with proper terminals to

prevent rain, snow and other objects from falling into

the Mighty Therm2.

If local codes allow, outdoor installations may

use 1' of appropriately sized galvanized single wall or

BVent and a rain cap for exhaust vent termination in

the default configuration (venting out of the top). Note

that some local codes may require a higher vertical

vent height, extending above any perimeter fencing,

etc. In installations where the appearance of the vent is

objectionable, the low profile vent terminals in

Table 6

may be used.

Combustion air inlets consist of appropriately

sized galvanized pipe and elbows to allow the open

end to face down aside the boiler. This is available as a

DISTANCE FROM GAS METER

OR LAST STAGE REGULATOR

MODEL AND

GAS TyPe

0-100' 0-31m 100-200' 31-61m 200-300' 61-91m

500 natural

1-1/2" 3.8cm 2"

5.1cm 2"

5.1cm

500 propane 1" 2.5cm 1-1/2" 3.8cm 1-1/2" 3.8cm

750 natural 2" 5.1cm 2"

5.1cm 2-1/2" 6.4cm

750 propane 1-1/2" 3.8cm 1-1/2" 3.8cm 2"

5.1cm

1000 natural 2" 5.1cm 2-1/2" 6.4cm 3"

7.6cm

1000 propane 1-1/2" 3.8cm 2"

5.1cm 2-1/2" 6.4cm

1250 natural 2-1/2" 6.4cm 2-1/2" 6.4cm 3"

7.6cm

1250 propane 2"

5.1cm 2"

5.1cm 2-1/2" 6.4cm

1500 natural 2-1/2" 6.4cm 3"

7.6cm 3"

7.6cm

1500 propane 2"

5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm

1750 natural 2-1/2" 6.4cm 3"

7.6cm 3"

7.6cm

1750 propane 2"

5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm

2000 natural 3" 7.6cm 3"

7.6cm 3-1/2" 8.9cm

2000 propane 2-1/2" 6.4cm 2-1/2" 6.4cm 3"

7.6cm

Notes:

1. These figures are based on 1/2" (0.12kPa) water column

pressure drop.

2. Check supply pressure and local code requirements before

proceeding with work.

3. Pipe fittings must be considered when determining gas pipe

sizing

.

Table 7. Gas Piping Size.

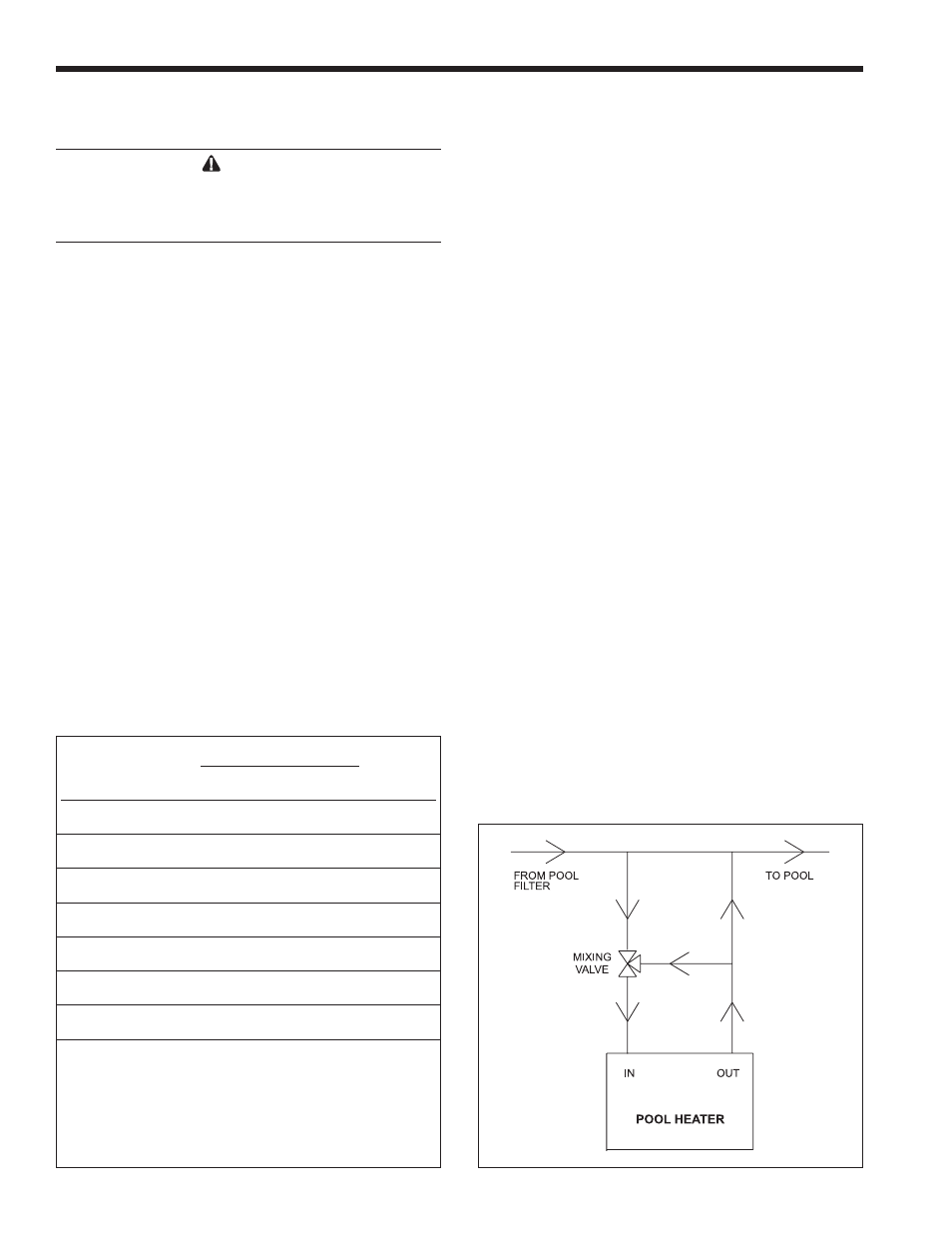

Figure 4. Mixing System.