2d. freeze protection, 2e. gas supply and piping – LAARS Mighty Therm HH (Sizes 2000-5000) - Installation, Operation and Maintenance Instructions User Manual

Page 8

LAARS Heating Systems

Page 8

wind conditions are possible, locate the boiler

at least three (3) feet from the structures.

3.

Never install the boiler under any kind of roof

overhang. Do not locate the boiler below or

adjacent to any doors, windows, louvers, grills,

etc. which communicate in any way with an

inhabited area of a building. Even though such

communication might be through another

structure such as a garage or utility room (see

Figure 6).

2D. Freeze Protection

Boiler installations are not recommended in

areas where the danger of freezing exists unless

proper precautions are made for freeze protection.

Maintaining a mixture of 50% water and 50%

ethylene glycol is the preferred method of freeze

protection for hydronic systems. This mixture will

protect the boiler to temperatures of about -35°F. To

get the desired temperature rise across the boiler

when this mixture is used, increase the G.P.M. flow

recommended for water by 15%. Increase the head

loss requirement by 20%.

2E. Gas Supply and Piping

Review the following instructions before

proceeding with the installation.

1.

Verify that the boiler is fitted for the proper

type of gas by checking the rating plate. Laars

boilers are normally equipped to operate below

a 2000 foot altitude. Boilers equipped to

operate at higher altitudes have appropriate

stickers or tags attached.

2.

Use the figures in Table 4 to provide adequate

gas piping (check local code for BTU capacity

required).

3.

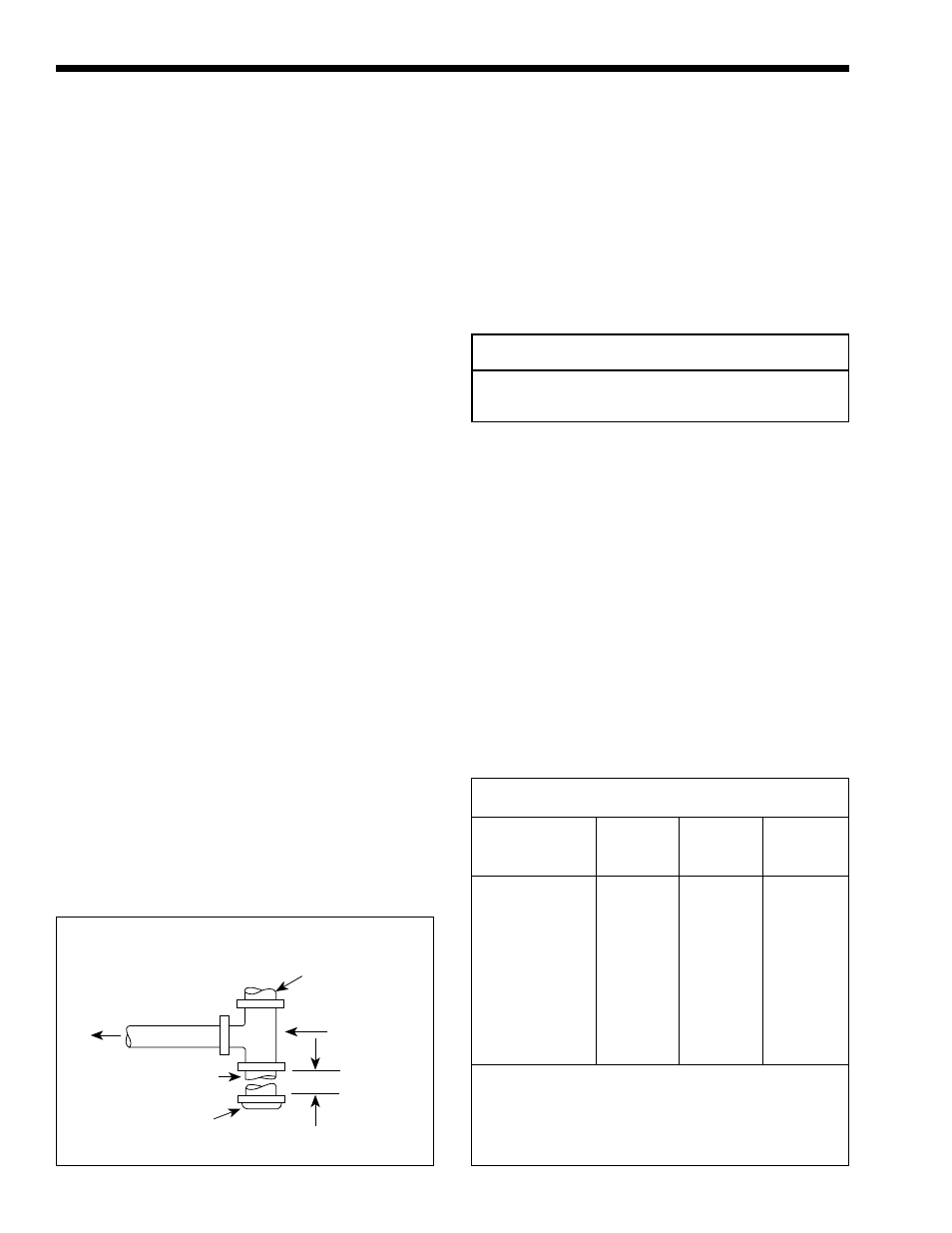

A trap (drip leg) must be provided ahead of the

gas controls (see Figure 7). Where required by

code, provide a second manual gas shutoff

valve. Do not remove manual valve furnished

with the boiler.

4.

The boiler and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of ½ psig. The boiler

must be isolated from the gas supply piping

system by closing its individual manual gas

shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than ½ psig.

5.

Provide gas supply pressure to the boiler as

follows:

Natural Gas

LPG

Min. (inches water column) 7 11

Max.(inches water column) 9 14

Note: The boiler and all other gas appliances

sharing the boiler gas supply line must be firing at

maximum capacity to properly measure the inlet

supply pressure. Low gas pressure could be an

indication of an undersize gas meter and/or obstructed

gas supply line.

6.

The correct burner manifold gas pressure is

stamped on the rating plate. The regulator is pre-

set at the factory, and normally requires no

further adjustment.

7.

The gas manifold and control assembly was

tested and conform to the safe lighting and other

performance criteria specified in the latest

editions of ANSI Z21.13 and CGA 3.3 Low

Pressure Boiler Standard.

Gas Supply

Inlet

Tee

Fitting

3" Min.

Nipple

Cap

To

Equipment

Inlet

Distance from Gas Meter or Last Stage Regulator

Indoor

Outdoor

0-100'

100-200'

200-300'

Size

Size

Nat.

Pro.

Nat.

Pro.

Nat.

Pro.

2000

------

2½

2

3

2½

3

3

2450

2200

3

2½

3

2½

3½

3

3050

2800

3

2½

3½

3

3½

3

3500

3200

3

2½

3½

3

4

3½

4050

3600

3½

3

4

3½

4

3½

4500

4000

3½

3

4

3½

5

4

5000

4500

4

3½

4

3½

5

4

NOTES:

These figures are based on 1/2" water column pressure drop.

Check supply pressure and local code requirements before

proceeding with work.

Pipe fittings must be considered when determining gas pipe sizing.

Figure 7. Method of Installing a Tee Sediment Trap.