LAARS Mighty Therm HH (Sizes 2000-5000) - Installation, Operation and Maintenance Instructions User Manual

Page 4

LAARS Heating Systems

Page 4

1B. Flow Requirements

All low volume hydronic boilers must have

continuous flow through the heat exchanger when

firing, for proper operation. The system pump must be

capable of developing sufficient pressure to overcome

the resistance of the boiler plus the entire circulating

system at the designated GPM (see Table 1). The

temperature rise across the boiler should never exceed

40° F.

NOTE: Water entering boiler should be 105°F

minimum.

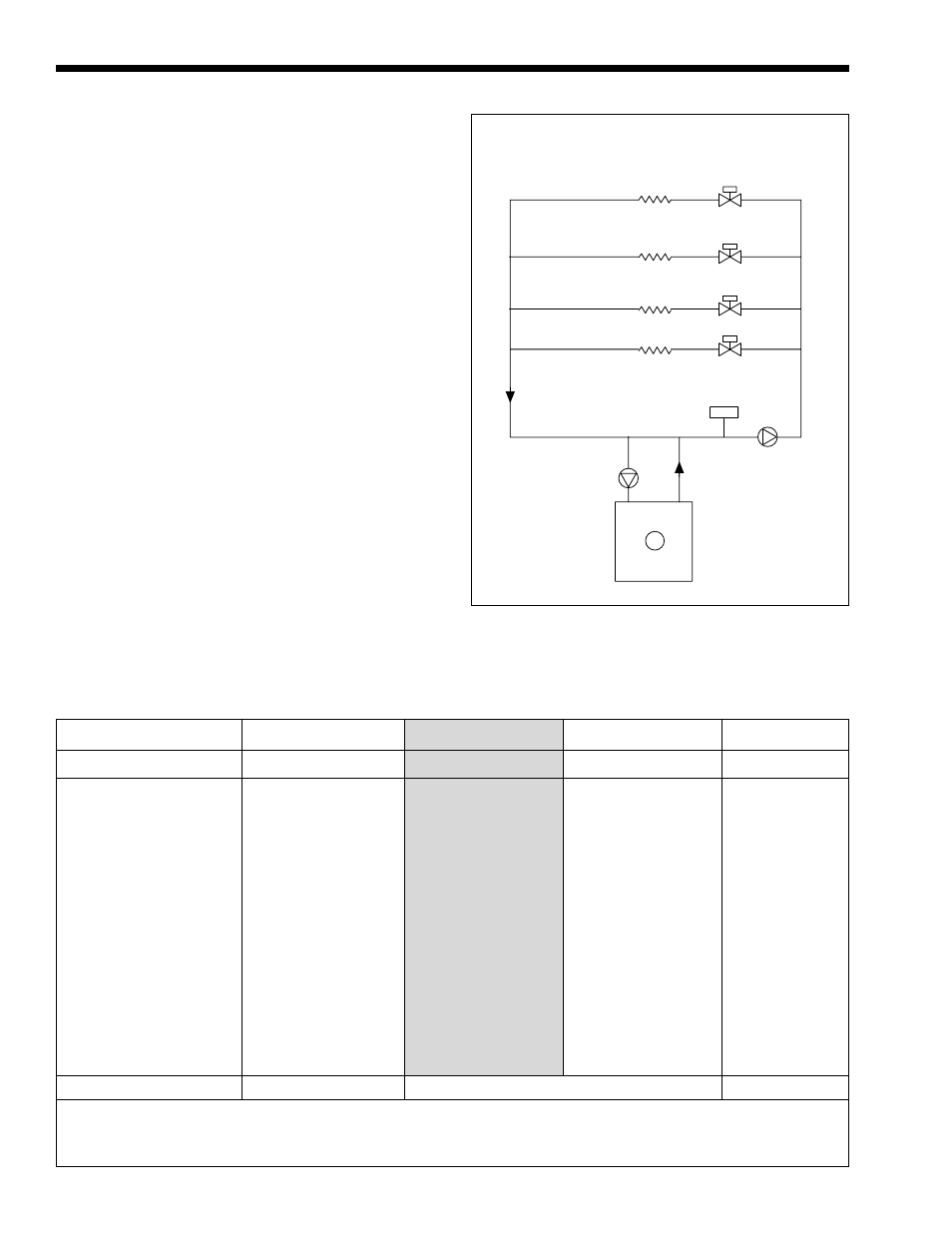

1C. Variable Water Flow Systems

Heating systems using zone valves, zone pumps

or 3-way valves can experience reduced water flow

through the boiler. This can result in an excessive

water temperature rise and unstable boiler operation. If

system water flow is variable, it must not be allowed

to fall below 30% of full flow. The boiler must be

equipped with staged or modulated fire with the

temperature sensor installed in the outlet water. State

variable flow when ordering. Laars recommends

primary-secondary pumping for all variable flow

systems. Primary-secondary pumping is mandatory for

variable flow systems where minimum flows are less

than 30% of full flow conditions. The boiler pump in a

primary-secondary system maintains constant flow

through the boiler even though the system flow is

variable. In a primary-secondary system the pressure

drop of the boiler is not added to the system (see

Figure 2).

Fan Coils

Zone Valves

Compression Tank

System Pump

Pump

(Location varies

with model)

Unit

12"

Max.

Convectors Baseboards

or Fan Coils

20°F

25°F

30°F

35°F

Size (I)

Size (E)

GPM

H/L

GPM

H/L

GPM

H/L

GPM

H/L

20001P

------

164

3.91

131

3.6

109

1.8

94

0.7

2P

------

164

10.5

131

7.4

109

4.9

94

3.0

24501P

22001P

201

5.9

161

3.9

134

3.8

115

2.3

2P

2P

201

16.4

161

10.2

134

7.7

115

5.7

30501P

28001P

250

9.3

200

5.9

167

4.5

143

3.8

2P

2P

*

*

200

16.4

167

12.5

143

8.5

35001P

32001P

284

12.0

230

8.7

189

5.7

164

3.9

2P

1P

*

*

*

*

189

16.8

164

10.5

40501P

36001P

332

17.2

266

11.9

222

8.1

190

5.8

2P

2P

*

*

*

*

222

24.0

190

16.0

45001P

40001P

369

21.75

295

13.2

246

10.0

211

7.0

2P

2P

*

*

*

*

*

*

211

20.0

50001P

45001P

410

27.0

328

16.8

273

13.0

234

9.0

2P

2P

*

*

*

*

*

*

*

*

HIGH

NORMAL

LOW

* Not recommended, consult factory.

I=Indoor, E=Outdoor. GPM=Water flow. H/H=Pressure drop (head loss)through the boiler, expressed in Ft. of H

2

0. 1P=Single-pass heat exchanger.

2P=Two-pass heat exchanger. Shaded area is the recommended flow and temperature rise.

Figure 2. Primary-Secondary System.

Table 1. Water Flow, Temperature Rise and Pressure Drop.