1d. warning regarding chilled water systems, 2a. boiler placement – LAARS Mighty Therm HH (Sizes 2000-5000) - Installation, Operation and Maintenance Instructions User Manual

Page 5

Mighty Therm Hydronic Boiler

Page 5

1C-1. A Special Note About 3-Way

Water Valves

3-way water valves (2 position or proportional)

are sometimes used to divert water around a boiler and

control the temperature of water being supplied to the

system. Valves installed in this manner must be

supplied with an end switch or some other suitable

control to shut off the boiler when the flow is reduced

to 30%. The boiler must be supplied with staged or

modulated fire as indicated in Section 1C, Variable

Water Flow Systems.

It is often possible to accomplish excellent water

temperature control without 3-way valves through

proper application of staged or modulated firing

systems. Consult the factory or local Laars

representative for assistance with such systems.

1C-2. System Pressure Requirements

The Model HH boilers are designed to operate

on closed, pressurized systems. A minimum of 12 psi

should be maintained on the system where boiler

supply water temperatures are 200°F or less. If higher

temperatures are required, the minimum system

pressure should be at least 15 psi above the water

vapor pressure corresponding to the elevated water

temperature.

The Model HH boilers are not suitable for

open systems unless the supply water temperatures are

kept below 180°F, and a minimum of 5 psi static head

is maintained at the boiler.

1D. Warning Regarding Chilled

Water Systems

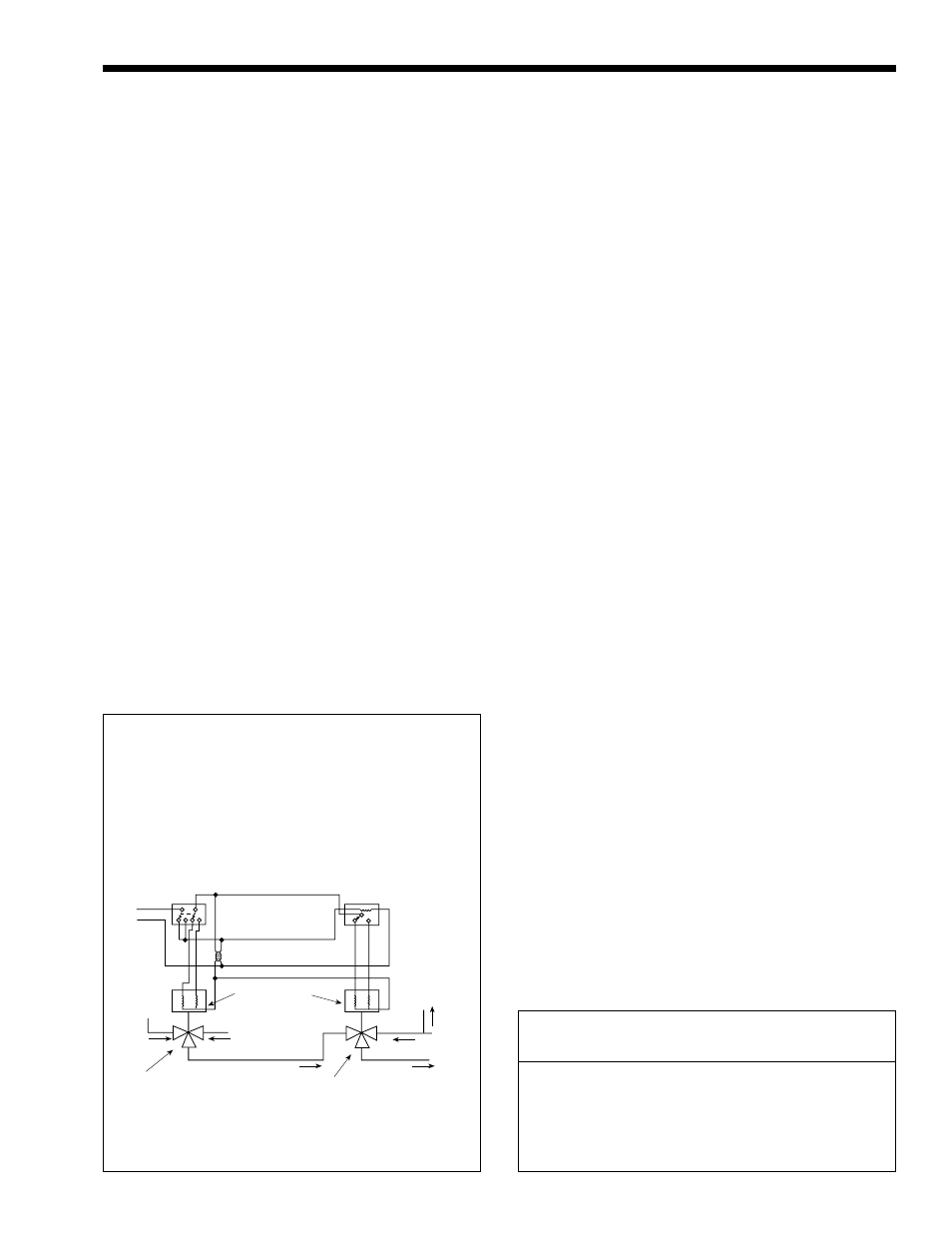

When a boiler is connected to an air conditioning

system where the same water is used for heating and

cooling, chilled water must be prevented from entering

the boiler. When changing such a system from cooling

to heating, the chilled water should be allowed to

circulate through the building after the chiller has been

turned off long enough for the water to warm up to at

least 70°F before the water is allowed to flow into the

boiler. It is equally important to prevent hot water

from entering the chiller. The system shown in Figure

3 is suggested to make sure that the system water is

neither too hot nor too cold when a changeover from

heating to cooling, or vice versa, takes place. When a

boiler is connected to heating coils located in air

handling units (where they may be exposed to

refrigerated air circulation), the boiler piping system

shall be equipped with a flow control valve or other

automatic means to prevent gravity circulation of

chilled water through the boiler. Chilled water in the

boiler will create condensate on the boiler tubes which

will drip on the burners and may extinguish the pilot.

Boilers installed in violation of either of the

above requirements may void the warranty.

SECTION 2.

Installation

2A. Boiler Placement

The boiler must be placed to provide clearances

on all sides for maintenance and inspection. There

must also be minimum distances maintained from

combustible surfaces.

All boilers must be installed on a non-

combustible floor. Under no circumstances can boilers

be installed on carpeting.

The National Fuel Code allows a boiler to be

placed on a combustible surface when such an

installation complies with the local codes. This code

specifies the surface under the boiler be protected with

hollow masonry no less than 4" thick, covered with

sheet metal at least 20 Ga. in thickness. Such masonry

DPDT Manual or Automatic

Change-over Switch

DPDT - Set at Change-over

Temperature

Clock Timer

Auto-resetting

Set at 15 minute SPDT

To Boiler

and

Chiller

From

System

To

System

3-Way Valve No. 2

To By-pass

Both Heater and

Chiller

3-Way Valve No. 1

Change-over

(Heating and Cooling)

From

Chiller

From

Boiler

Valve Motors

2-Pos

3-Wire - 24V

115/24V

Transformer

By-pass

Clearance

Indoor

Outdoor

From

(Inches)

(Inches)

Top

24

—

Water Connection Side

24

24

Opposite Side

24

24

Front

48

48

Rear

24

24

Vent

6

—

Suggested Wiring Diagram For

Tempering System Water at

Changeover from Heating to Cooling

Figure 3. Boiler-Chiller Installation.

Table 2. Minimum Clearances from Combusible Surfaces.