LAARS Mighty Therm HH-PH (Sizes 175-400) - Installation, Operation and Maintenance Instructions User Manual

Page 21

Mighty Therm HH-PH Hydronic Boilers

Page 21

b.

Flame is not lifting off the burner ports

4.

Inspect the venting system for blockage, leakage,

and corrosion at least once a year.

5.

Keep the equipment area clear of combustible

material, gasoline, and other flammable liquids

and vapors.

6.

Be sure all combustion air and ventilation

openings are not blocked.

7.

Check for black carbon soot buildup on the

external surfaces of the heat exchanger every 6

months. If cleaning is necessary, see the

instructions in this section.

8.

On a unit with the optional low water cutoff,

check the device to be sure it is functioning

correctly.

9.

Do not use the boiler if any part has been under

water. Replace any part of the gas control and

control system, or any tile material or insulation

which has been under water.

4B. Replacement of Gas Controls

WARNING

Never attempt to repair the gas valve. Such

attempts will void the warranty, and could lead to

dangerous results.

If the gas valve is found to be defective, replace

it by following these instructions:

1.

Turn all electrical power to the boiler OFF.

2.

Turn off the main gas supply at the manual gas

cock or the gas meter.

3.

Remove the front access door on the boiler.

4.

Turn OFF the gas valve to the boiler following

the shut-down instructions found on the inside of

the boiler.

5.

Disconnect the service union in the gas line, and

unscrew the main gas pipe from the gas valve

(see Figure 32).

6.

Remove the two screws that fastens the anti-

rotation bracket on the left side of the gas valve

(see Figure 32).

7.

Remove the pilot gas line and thermocouple

shield, if present, from the gas valve.

Caution

Label all wires before disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

3E. Shut-Down Procedure

Shut the boiler down following the instructions

found on the inside of the boiler.

Where there is a danger of freezing, shut off the

water supply and remove the drain plugs on both sides

of the boiler jacket. Drain every part of the system

subject to damage from freezing temperatures.

SECTION 4.

Service Instructions

4A. Regular Inspection

NOTE: After installation and first startup, check

the heat exchanger for black carbon soot buildup after

the following periods of operation: 24 hours, 7 days,

30 days, 90 days, and once every 6 months thereafter.

If cleaning is necessary, see the instructions in this

section.

1.

Oil the water circulating pump in accordance

with the manufacturer’s instructions.

2.

If a strainer is used in a pressure reducing valve

or in the piping, clean it every 6 months in

accordance with the manufacturer’s instructions.

3.

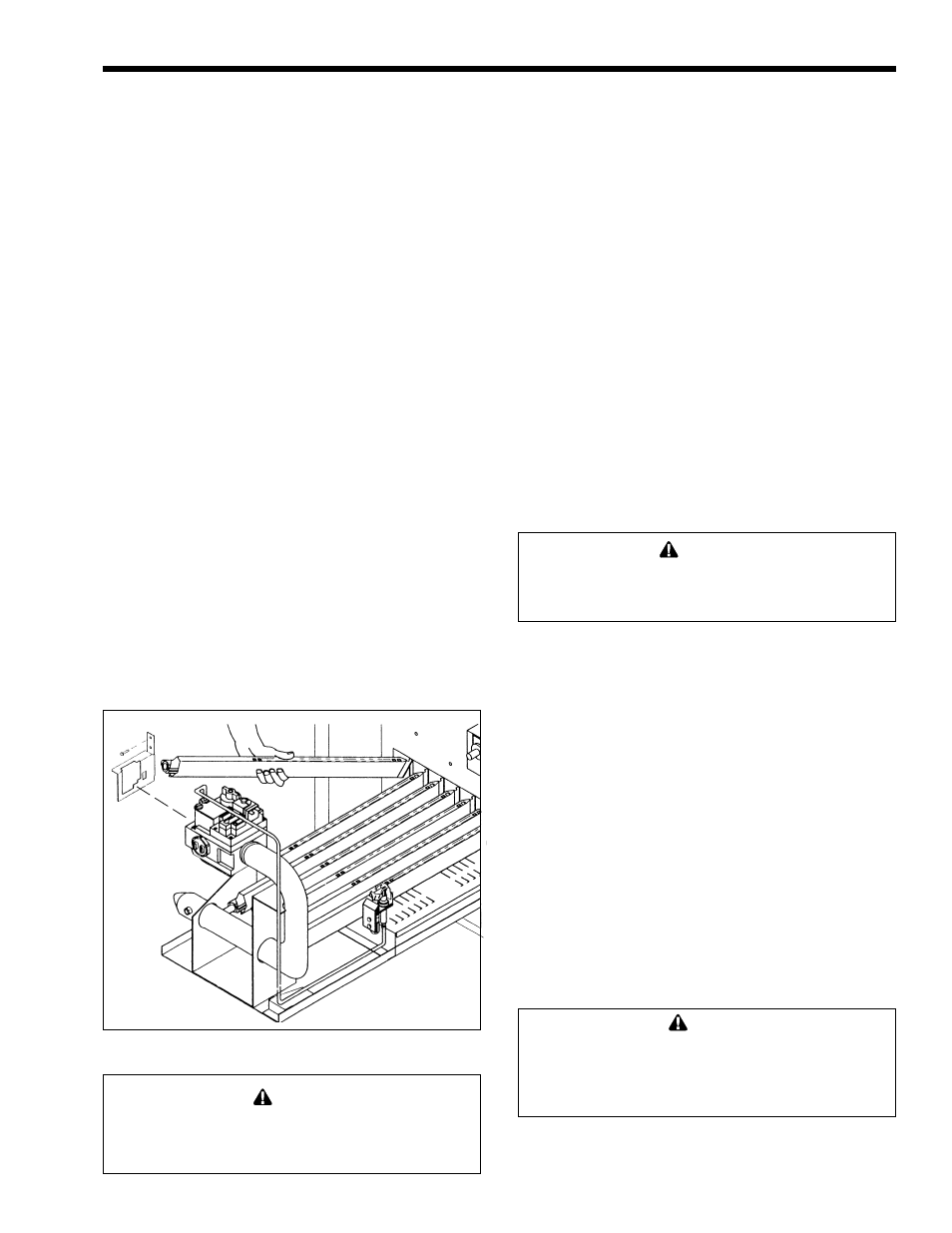

At startup and every 6 months after, look at the

pilot and main burner flame (see Figure 31). Use

inspection mirror. Characteristics of a good

flame are:

a.

Blue in color

Figure 32. Burner Removal and Gas Valve.

Caution

Since some leak test solutions (including soap and

water) may cause corrosion or stress cracking,

rinse the piping with water after testing.