LAARS Mighty Therm HH-PH (Sizes 175-400) - Installation, Operation and Maintenance Instructions User Manual

Page 16

LAARS HEATING SYSTEMS

Page 16

with CAN1-B149.1 or .2 and all local codes

that apply.

2.

Check the rating plate to make sure the boiler is

fitted for the type of gas being used. Laars

boilers are normally equipped to operate below a

2000 foot (610 m) altitude. Boilers equipped to

operate at higher altitudes have appropriate

stickers or tags attached.

3.

If a gas pressure regulator is required, the

installation must be in accordance with the latest

edition of ANSI Z223. In Canada, the installation

must be in accordance with CAN1-B149.1 or .2

and all local codes that apply.

4.

The figures in Table 4 should be used to size the

gas piping from the gas meter to the boiler.

5.

Install a sediment trap (drip leg) ahead of the gas

controls (see Figure 27). Fit the trap with a

threaded cap which can be removed for cleaning.

6.

Install a manual gas shut-off valve for service

and safety. Check the local codes.

7.

Disconnect the boiler and its individual shut-off

valve from the gas supply system during pressure

test of the system at pressures higher than ½ psi

(3.4 kPa).

8.

Gas supply pressures to the boiler are listed in

Table 5.

NOTE: The boiler and all other gas appliances

sharing the boiler gas supply line must be firing at

maximum capacity to properly measure the inlet

supply pressure. Low gas pressure could be an

indication of an undersize gas meter and/or obstructed

gas supply line.

9.

Do not exceed the maximum inlet gas pressures

specified. Excessive pressure will result in

damage to the heater's gas controls. The

minimum pressures specified is for gas input

adjustment.

10. The correct burner manifold gas pressure is

stamped on the rating plate. The regulator on the

gas valve is preset at the factory, and does not

normally need adjustment.

11. Before operating the boiler, test the complete gas

supply system and all connections for leaks using

a soap solution.

Caution

Since some leak test solutions (including soap and

water) may cause corrosion or stress cracking,

rinse the piping with water after testing.

2G-2. Special Precautions for Propane Gas

Propane gas is heavier than air. Therefore, do not

install boilers using propane gas in a pit or locations

where gas might collect. Locate boilers a safe distance

from propane gas storage and filling equipment.

Supply Pressure

Natural Gas

Propane Gas

Water Column

in.

kPa

in.

kPa

Minimum

6.5

1.6

11

2.7

See Rating Plate

Maximum

10

2.5

14

3.4

Table 5. Gas Supply Pressure Requirements.

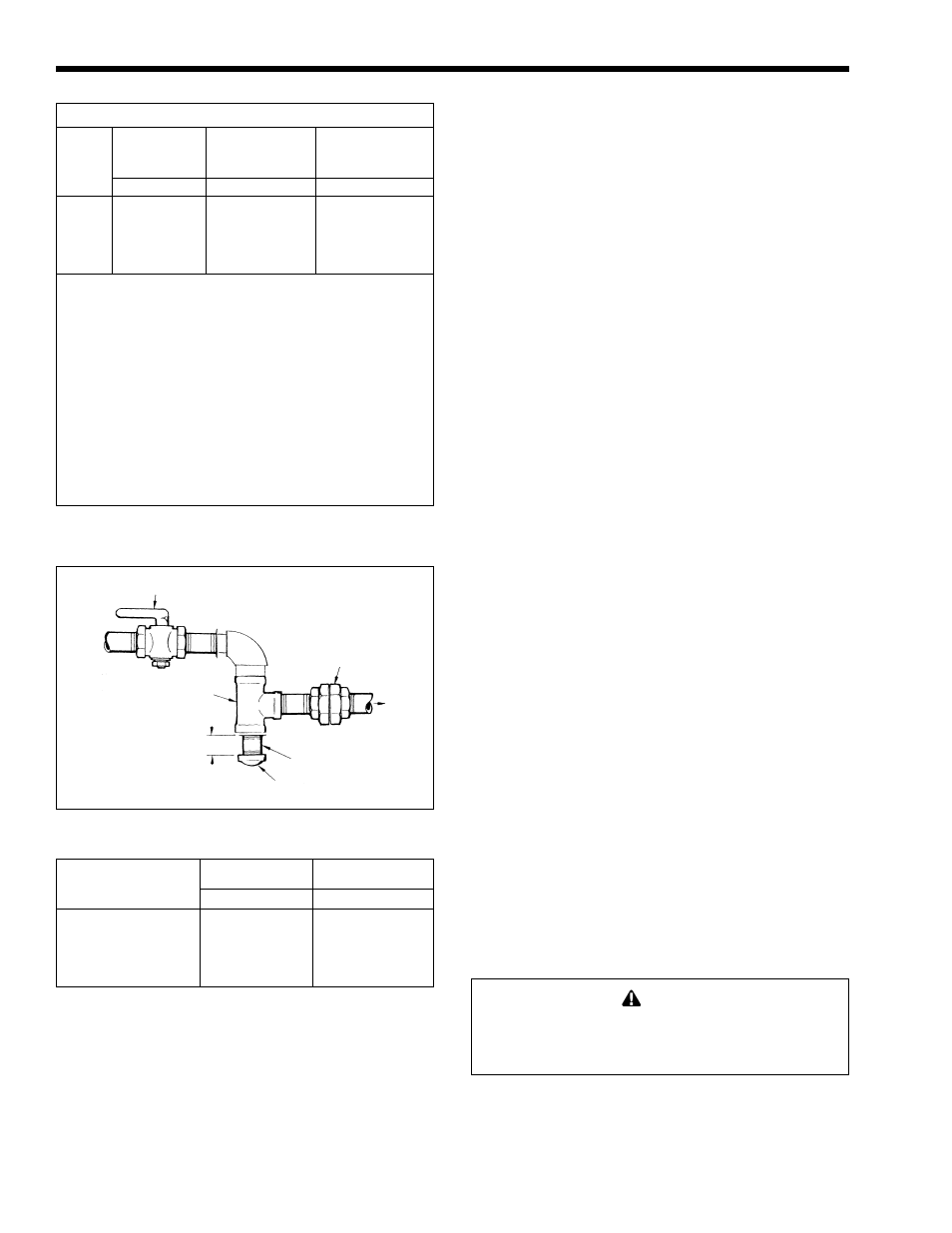

Figure 27. T-Fitting and Sediment Trap.

MANUAL SHUT-OFF

VALVE

GAS

SUPPLY

INLET

T-FITTING

3" (76 mm)

MIN.

UNION

NIPPLE

CAP

TO

BOILER

INLET

Distance from Gas Meter or Last Stage Regulator

0-100 feet

100-200 feet

200-300 feet

0-30 m

30-60 m

60-90 m

Boiler

Nat.

Nat.

Nat.

Size

in.

mm

in.

mm

in.

mm

175

1

25

1¼

32

1¼

32

250

1¼

32

1¼

32

1½

38

325

1¼

32

1½

38

1½

38

400

1¼

32

1½

38

2

51

Notes:

1. These numbers are for natural gas (0.65 Sp. Gr.) and

are based on ½ inch (13mm) water column pressure

drop. Check supply pressure with a manometer, and

local code requirements for variations. For liquefied

petroleum gas, reduce pipe diameter one size, but

maintain a ½ inch (13mm) minimum diameter.

2. Check supply pressure and local code requirements

before preceding with work.

3. Pipe fittings must be considered when determining

gas pipe sizing.

4. For propane gas: Reduce pipe diameter one size, but

maintain a ¾ inch (19mm) minimum diameter.

Table 4. Natural Gas and Propane,

Pipe Size Requirements.

2G. Gas Supply and Piping

2G-1. General Instructions

Review the following instructions before

continuing the installation.

1.

Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance