LAARS Mascot LX MLXC 175 MBH - Install and Operating Manual User Manual

Page 14

LAARS Heating Systems

Page 10

3.2 Venting (Exhaust)

The flue temperature of the Mascot LX changes

dramatically with changes in operating water

temperature. Therefore, it is necessary to assess the

application of the boiler to determine the required

certified vent class. If the Mascot LX is installed in

an application where the ambient temperature is

elevated, and/or installed in a closet/alcove, CPVC,

polypropylene, or stainless steel material is required.

If the system temperatures are unknown at the time

of installation, stainless, polypropylene or CPVC

material is recommended.

The Mascot LX is a Category IV appliance and may

be installed with PVC, CPVC or polypropylene that

complies with ULC-S636, ANSI/ASTM D1785 F441

(see

Table 4)

or a stainless steel venting system that

complies with UL 1738 Standard (see

Table 8

).

WARNING

Failure to use the appropriate vent material, installation

techniques, glues/sealants could lead to vent failure

causing property damage, personal injury or death.

have a minimum free area of 1 square inch per 3000

Btu/hr (734 square mm/kW) of the total input rating of

all equipment located in the enclosure. This opening

must not be less than the sum of the areas of all vent

connectors in the confined space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform to

the requirements in the applicable codes listed above.

In Canada, consult local building and safety codes or, in

absence of such requirements, follow CAN/CGA B149.

3.1.2 Ducted Combustion Air

The combustion air can be taken through the wall, or

through the roof. When taken from the wall, it must

be taken from out-of-doors by means of the LAARS

horizontal wall terminal, shown in

Table 5

. See

Table 4

to select the appropriate diameter air pipe. When taken

from the roof, a field-supplied rain cap or an elbow

arrangement must be used to prevent entry of rain water

(see

Figure 5

).

Use ABS, PVC, CPVC, polypropylene, or galvanized

pipe for the combustion air intake (see

Table 6

), sized

per

Table 4

. Route the intake to the boiler as directly

as possible. Seal all joints. Provide adequate hangers.

The unit must not support the weight of the combustion

air intake pipe. Maximum linear pipe length allowed is

shown in

Table 4

. Subtract 5 allowable linear ft. (1.5m)

for every elbow used.

The connection for the intake air pipe is at the top of the

unit (see

Figure 3

).

In addition to air needed for combustion, air shall also

be supplied for ventilation, including air required for

comfort and proper working conditions for personnel.

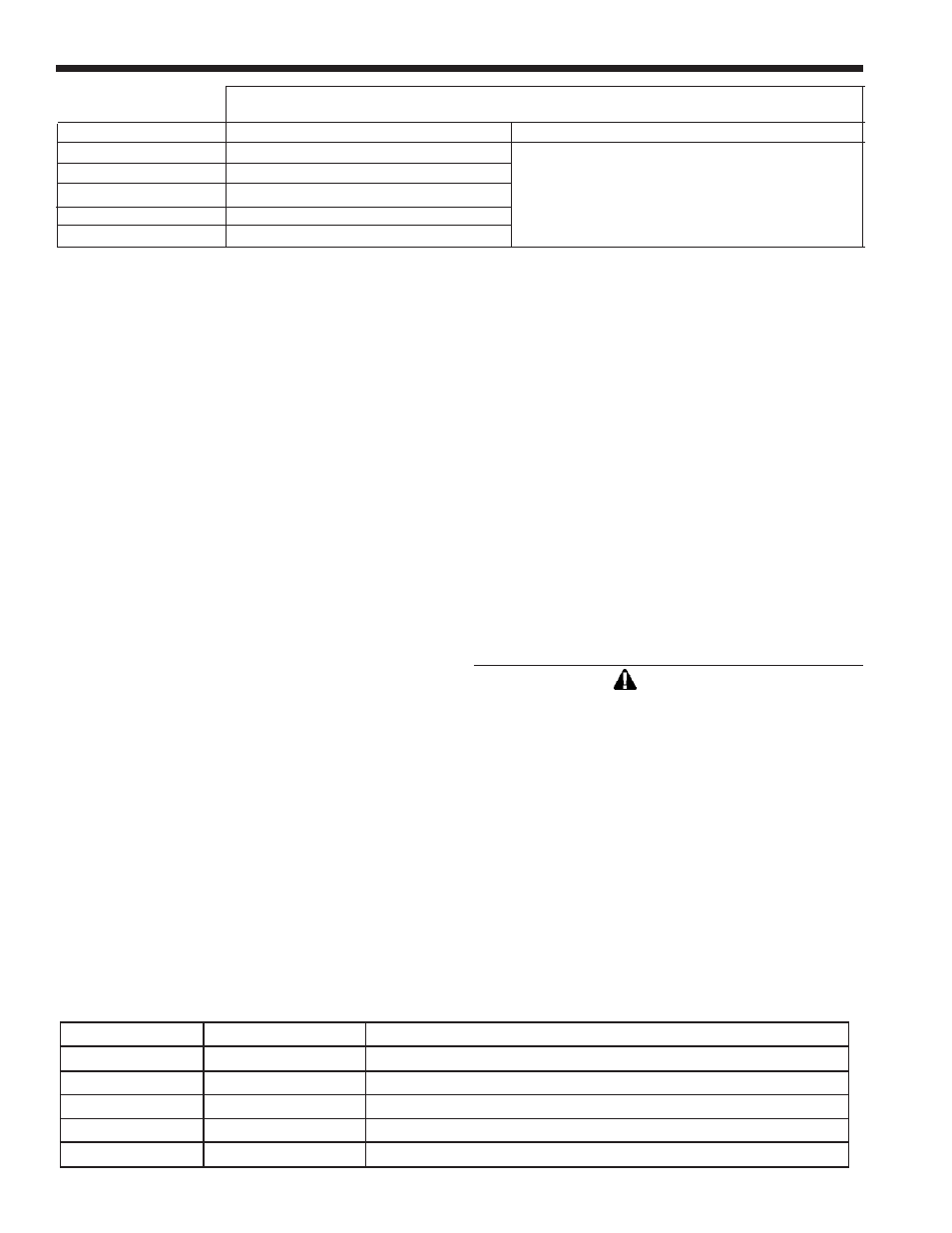

Table 5. Vent Termination Options

Part Number

Size

Description

239-44069-02

2"

PVC Concentric Vent Terminal

239-44069-01

3"

PVC Concentric Vent Terminal

CA010101

2"

Flush Vent Terminal PVC

CA010100

3"

Flush Vent Terminal PVC

CA007100

3" to 5"

Stainless Steel Concentric Vent Terminal

INSTALLATION STANDARDS

MATERIAL

UNITED STATES

CANADA

ABS

ANSI/ASTM D1527

PVC, sch 40

ANSI/ASTM D1785 or D2665

Air pipe material must be chosen

CPVC, sch 40

ANSI/ASTM F441

CPVC, sch 40, ANSI/ASTM, Polypropylene

Polypropylene

UL1738, ULC S636.

based upon the intended application of the boiler.

Single wall galv. steel

26 gauge

Table 6. Required Combustion Air Pipe Material.

- Mascot LX MLXC 150 MBH - Install and Operating Manual Mascot LX MLXC 125 MBH - Install and Operating Manual Mascot LX MLXH 220 MBH - Install and Operating Manual Mascot LX MLXH 175 MBH - Install and Operating Manual Mascot LX MLXH 150 MBH - Install and Operating Manual Mascot LX MLXH 125 MBH - Install and Operating Manual Mascot LX MLXH 100 MBH - Install and Operating Manual Mascot LX MLXH 75 MBH - Install and Operating Manual Mascot LX MLXH 50 MBH - Install and Operating Manual