Carrier SERIES 131 58PAV User Manual

Page 5

8. Clean cells using field-provided small wire brush, steel spring

cable, reversible electric drill, and vacuum cleaner.

a. Assemble wire brush and steel spring cable.

(1.) Use 48 in. of 1/4-in. diameter high-grade steel spring

cable (commonly known as drain clean-out or Roto-

Rooter cable).

(2.) Use 1/4-in. diameter wire brush (commonly known as

25-caliber rifle cleaning brush).

NOTE:

The materials needed in items (1.) and (2.) can usually be

purchased at local hardware stores.

(3.) Insert twisted wire end of brush into end of steel spring

cable, and crimp tight with crimping tool or strike with

ball-peen hammer. TIGHTNESS is very important.

(4.) Remove metal screw fitting from wire brush to allow

insertion into cable.

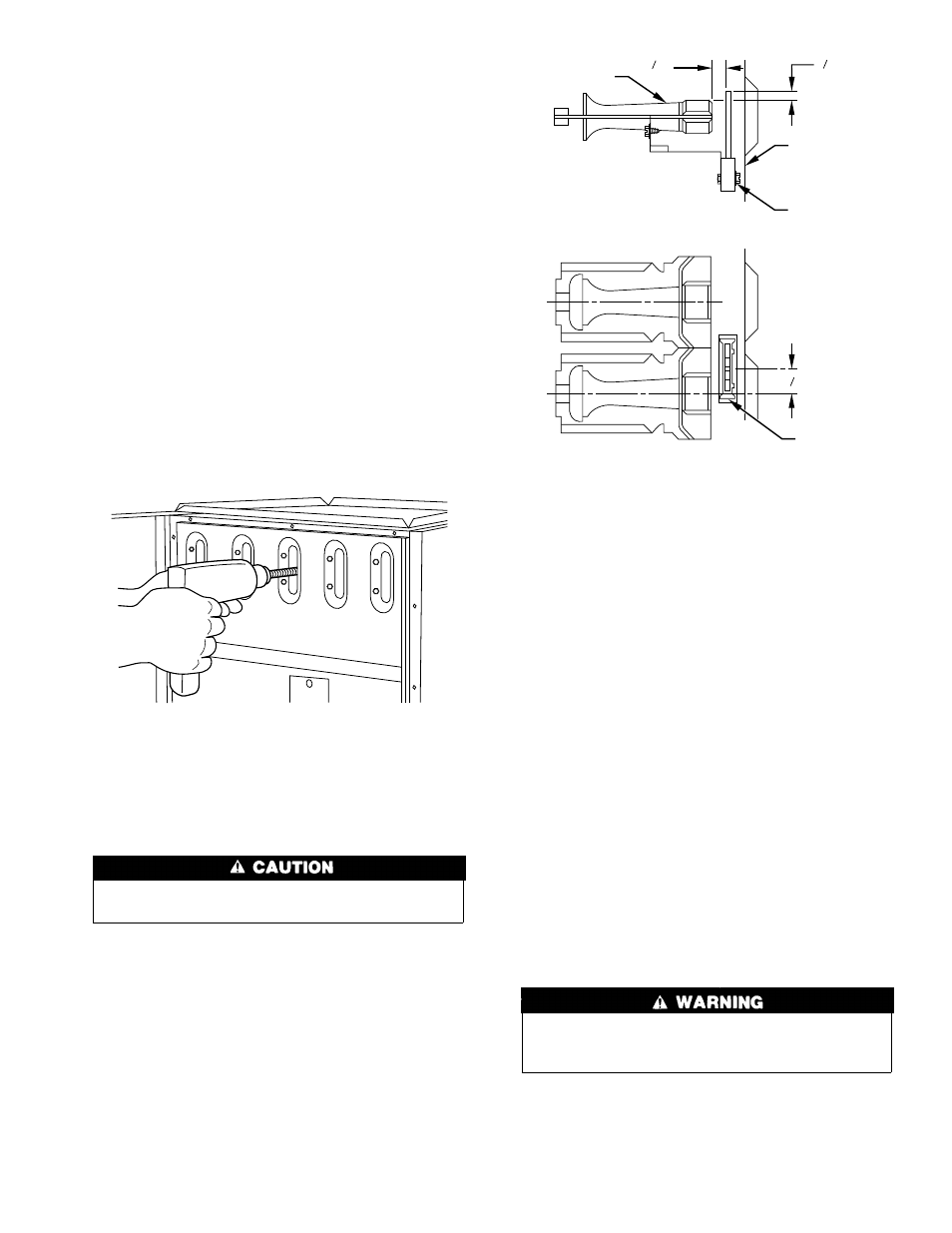

b. Clean each heat exchanger cell.

(1.) Attach variable-speed, reversible drill to end of steel

spring cable (end opposite brush).

(2.) Insert brush end of cable into upper opening of cell

and slowly rotate with drill. DO NOT force cable.

Gradually insert at least 36 in. of cable into 2 upper

passes of cell. (See Fig. 8.)

(3.) Work cable in and out of cell 3 or 4 times to obtain

sufficient cleaning. DO NOT pull cable with great

force. Reverse drill and gradually work cable out.

(4.) Remove burner assembly and cell inlet plates.

Be very careful when removing the burner assembly to avoid

breaking the ignitor. See Fig. 9 for the correct ignitor location.

(5.) Replace screws in center panel and cells before

cleaning.

(6.) Insert brush end of cable in lower opening of cell, and

proceed to clean 2 lower passes of cell in same manner

as 2 upper passes.

(7.) Repeat foregoing procedures until each cell in furnace

has been cleaned.

(8.) Remove residue from each cell using vacuum cleaner.

(9.) Clean burner assembly using vacuum cleaner with soft

brush attachment.

(10.) Reinstall cell inlet plates and burner assembly. Care

must be exercised to center the burners in the cell

openings.

9. After cleaning flue openings, check sealant on flue collector to

ensure that it has not been damaged. If new sealant is needed,

contact your dealer or distributor.

10. Clean and replace flue collector assembly, making sure all 8

screws are secure.

11. Reinstall relief box.

12. Reconnect wires to the following components.

a. Draft safeguard switch

b. Inducer motor

c. Pressure switch

d. Limit overtemperature switch(es)

e. Gas valve

f. Hot surface ignitor

g. Flame-sensing electrode

h. Two wiring connectors leading to control

13. Reconnect vent pipe to relief box. Replace vent pipe enclosure

(downflow/horizontal furnace only).

14. Replace blower access door only.

15. Turn on electrical power and gas.

16. Set thermostat and check furnace for proper operation.

Never use a match or other open flame to check for gas leaks.

Use a soap-and-water solution. A failure to follow this

warning could result in fire, personal injury, or death.

17. Check for gas leaks.

18. Replace control access door on upflow furnace.

19. On downflow/horizontal furnaces, remove blower access

door, replace control access door first, then replace blower

access door and secure with 2 screws in front of door.

Fig. 8—Cleaning Heat Exchanger Cell

A91252

Fig. 9—Position of Ignitor to Burner

A93347

BURNER

IGNITOR

11 32

"

7 8

"

C

L

C

L

IGNITOR

ASSEMBLY

CELL

PANEL

BURNER

13 32

"

HOT

SURFACE

IGNITOR

ASSEMBLY

5