Carrier 50HCQA User Manual

Page 22

22

If the 50HCQ unit has an economizer system and

free--cooling operation is required, a sensor representing

Return Air Temperature must also be connected

(field--supplied and installed). This sensor may be a T--55

Space Sensor (see Fig. 31) installed in the space or in the

return duct, or it may be sensor PNO 33ZCSENSAT,

installed in the return duct. Connect this sensor to TB1--1

and TB1--3 per Fig. 32.

Configure the Unit for Thermostat Mode —

Connect to the CCN bus using a CCN service tool and

navigate to PremierLink Configuration screen for

Operating Mode. Default setting is Sensor Mode (value

1). Change the value to 0 to reconfigure the controller for

Thermostat Mode.

When the PremierLink is configured for Thermostat

Mode, these functions are not available: Fire Shutdown

(FSD), Remote Occupied (RMTOCC), Compressor Safety

(CMPSAFE), Supply Fan Status (SFS), and Filter Pressure

Switch (FILTER).

Economizer Controls

Outdoor Air Enthalpy Control

(PNO 33CSENTHSW) —

The enthalpy control (33CSENTHSW) is available as a

field--installed accessory to be used with the EconoMi$er2

damper system. The outdoor air enthalpy sensor is part of

the enthalpy control. (The separate field--installed

accessory return air enthalpy sensor (33CSENTSEN) is

required for differential enthalpy control. See Fig. 36.)

Locate the enthalpy control in the economizer next to the

Actuator Motor. Locate two GRA leads in the factory

harness and connect the gray lead labeled “ESL” to the

terminal labeled “LOW”. See Fig. 36. Connect the

enthalpy control power input terminals to economizer

actuator power leads RED (connect to 24V) and BLK

(connect to GND).

7

ESL

CTB

ECON

LOW

GND

24V

Enthalpy

Switch

GRA

BLK

RED

Factory Wiring Harness

ECONO

MOTOR

C09026

Fig. 36 -- Enthalpy Switch (33CSENTHSW) Connections

The outdoor enthalpy changeover setpoint is set at the

enthalpy controller.

Differential Enthalpy Control —

Differential enthalpy control is provided by sensing and

comparing the outside air and return air enthalpy

conditions. Install the outdoor air enthalpy control as

described above. Add and install a return air enthalpy

sensor.

Return Air Enthalpy Sensor —

Mount the return--air enthalpy sensor (33CSENTSEN) in

the return--air section of the economizer. The return air

sensor

is

wired

to

the

enthalpy

controller

(33CSENTHSW). See Fig. 37.

ESL

LOW

GND

24V

GRA

BLK

RED

ECONO

MOTOR

– 4-20

Main

+ VDC

Out

– 4-20 Main

Out

+ 24-36

VDC In

C09027

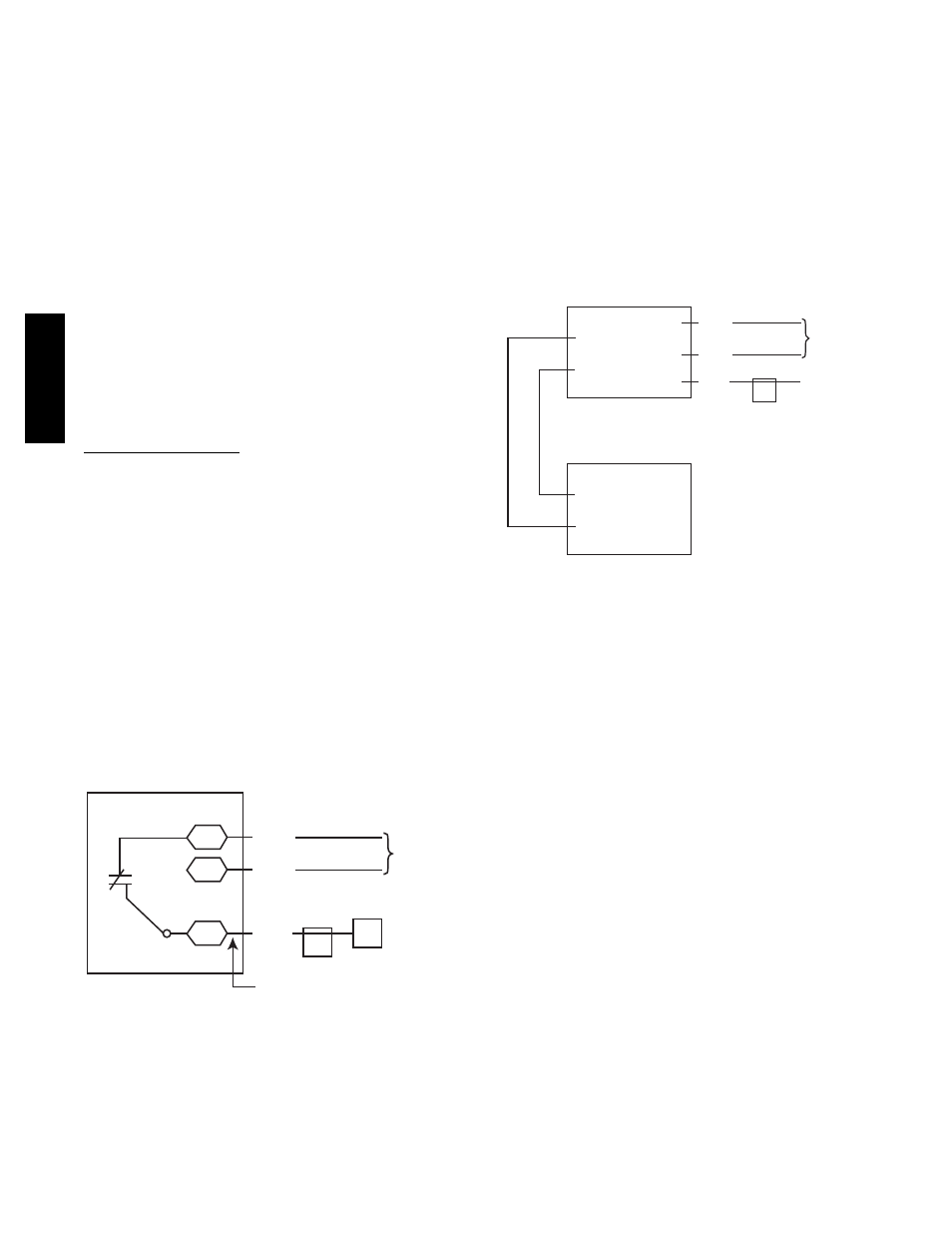

Fig. 37 -- Outside and Return Air Enthalpy Sensor

Wiring

To wire the return air enthalpy sensor, perform the

following:

1. Use a 2--conductor, 18 or 20 AWG, twisted pair cable

to connect the return air enthalpy sensor to the enthal-

py controller.

2. Connect the field--supplied RED wire to (+) spade

connector on the return air enthalpy sensor and the

(+) terminal on the enthalpy controller. Connect the

BLK wire to (--) spade connector on the return air en-

thalpy sensor and the (--) terminal on the enthalpy

controller.

Indoor Air Quality (CO

2

sensor) —

The indoor air quality sensor accessory monitors space

carbon dioxide (CO

2

) levels. This information is used to

monitor IAQ levels. Several types of sensors are available,

for wall mounting in the space or in return duct, with and

without LCD display, and in combination with space

temperature sensors. Sensors use infrared technology to

measure the levels of CO

2

present in the space air.

The CO

2

sensors are all factory set for a range of 0 to

2000 ppm and a linear mA output of 4 to 20. Refer to the

instructions supplied with the CO

2

sensor for electrical

requirements and terminal locations. See Fig. 38 for

typical CO

2

sensor wiring schematic.

50H

C

Q

A