Wing assembly – Great Planes Super Decathlon 40 Kit - GPMA0185 User Manual

Page 9

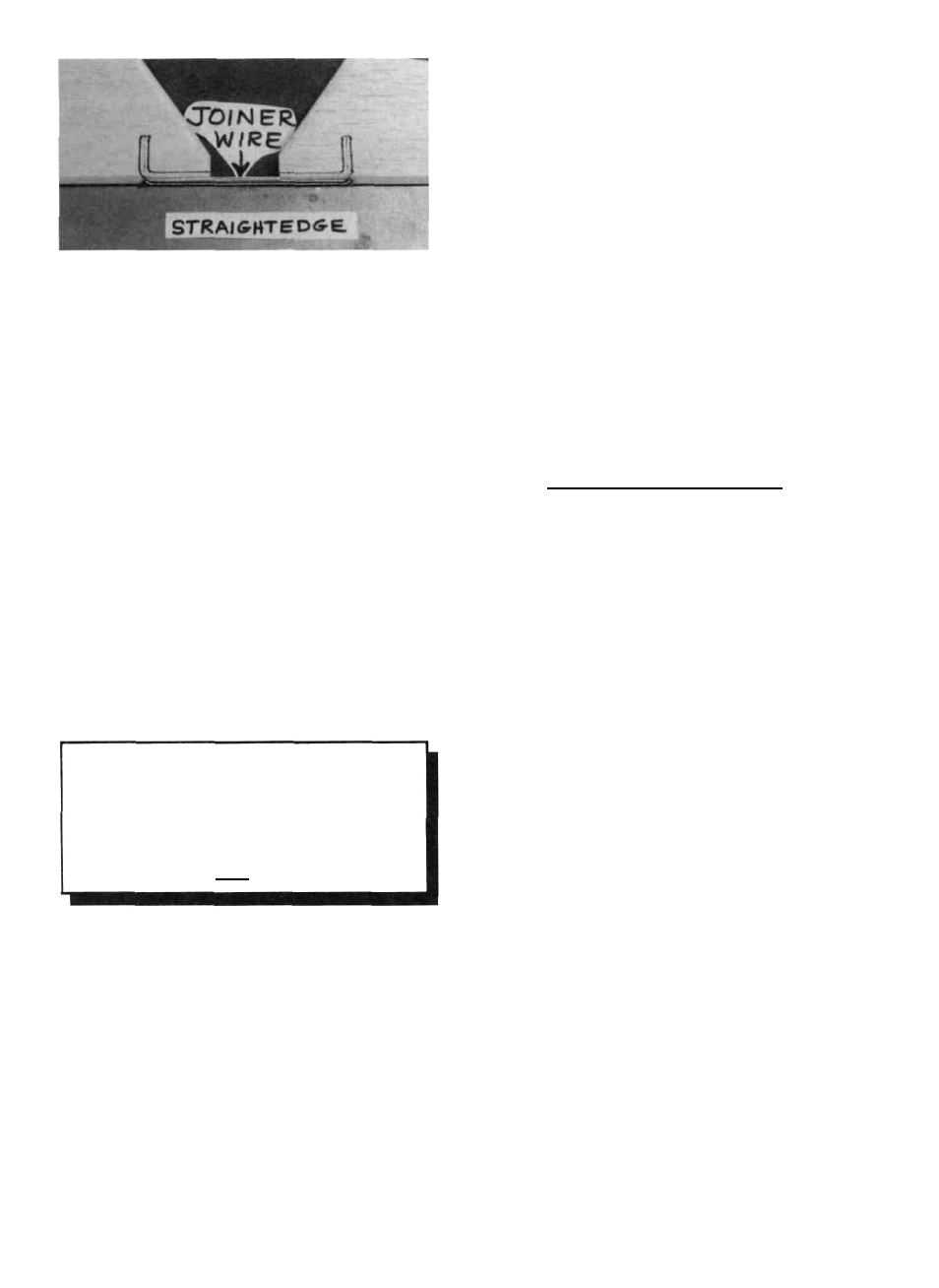

D 10. Trial fit the joiner wire into the elevators, then glue

it in using 5-minute or 30-minute epoxy. When gluing, lay

the elevators on a flat surface, with the leading edges along a

straightedge to insure perfect alignment

B. Make three or four more cuts in the same line,

going slightly deeper each time. As you make these

additional cuts, work on going straight into the wood.

Continue this process while "wiggling" the knife

handle back and forth until the blade has reached the

proper depth for the hinge.

C. Trial fit the hinge into the slot. If the hinge is

difficult to push in, re-insert the knife and move it back

and forth in the slot a few times to enlarge the slot

D 3. IMPORTANT! Condition or "break-in" the

hinges by folding them back and forth several times.

D 4. Insert the hinges into the slots and trial fit the rudder

and elevators in place on the fin and stab. Do not glue the

hinges until after you have covered the model.

INSTALL THE HINGES (Do not glue)

NOTE: One-piece molded polypropylene hinges are

supplied in this kit. If you choose to use these hinges or

the' 'pinned' '-type hinges, you may cut the hinge slots at

this time. However, if you choose to use the one-piece

hinges that are paper covered for CA glue installation,

you may wait until after covering before cutting the hinge

slots, because this will be easier than trying to find the

slot locations under the covering.

D 1. Lay the rudder and elevators on the plan and mark

the hinge locations. Place the rudder against the fin TE and

transfer the marks over to the fin. Place the elevators against

the stab TE and transfer the marks over to the stab.

CAUTION!!!: You must use extreme care when

cutting hinge slots with an Xacto knife, to avoid

cutting yourself! If the balsa part breaks while you

are pushing on the knife, the blade could go into your

hand before you know it! A good precaution is to

wear leather gloves while performing the following

steps, and always cut awav from yourself.

D 2. Cut the hinge slots on the accurate centerlines

which you previously drew, using an Xacto knife or a

slotting fork and slotting hook. (The recommended hinge

slotting technique is listed below).

A. Begin by carefully cutting a very shallow slit at

the hinge location. This first cut is to establish your cut

in the right place, so concentrate on staying on the

centerline and don't cut too deep!

WING ASSEMBLY

BUILD THE WING PANELS

NOTE: The following instructions explain how to build

the wing directly on the plans. An alternate method is to

use a Great Planes Wing Jig (available from your local

hobby dealer). Many expert modelers prefer to use a

wing jig for high performance airplanes, as it helps to

insure a straight, warp-free wing, especially if you do not

have a workbench or building board that is perfectly flat.

If you choose to use the Wing Jig, please read the

instructions that are included with the jig before

beginning.

NOTE: It will be helpful to build the wing on a piece of

"Celotex" or other semi-soft (and flat) surface, into

which you may easily stick pins to firmly hold down the

wing pans while building, to avoid warps.

D 1. Tape the plan to your flat work surface, and cover

the wing drawing with waxed paper (so you won't glue the

wing to the plan!). NOTE; If your work space is limited, you

may cut the left and right wing half drawings apart

D 2. The shaped and notched wing leading edges (LE)

and trailing edges (TE) are fastened together by thin strips of

balsa. Separate them by folding until the balsa breaks. Sand

away the excess balsa that remains along the edges after

breaking them apart, using a T-bar with 100-grit sandpaper.

9