Drilling locations – Great Planes Super Decathlon 40 Kit - GPMA0185 User Manual

Page 24

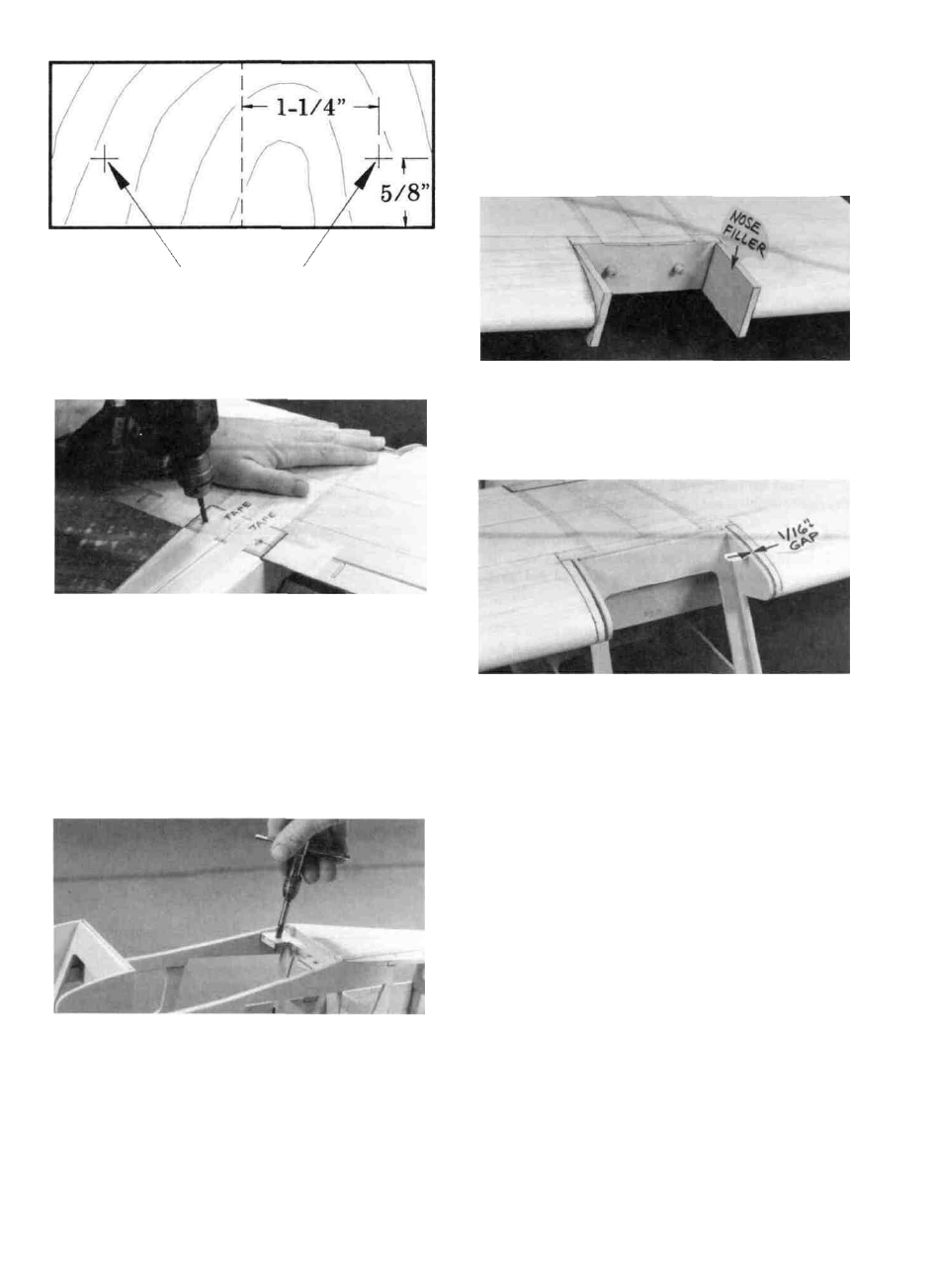

DRILLING LOCATIONS

D 17. Trial fit the wing to the fuse using the two 1/4-20

nylon bolts provided. You may cut the bolts off to their proper

length, so they protrude about 1/4" below the hold-down

blocks in the fuselage. Check the incidence of the wing using

the instructions provided at the bottom of page 41.

D 13. Holding the wing firmly in place, drill 13/64" holes

at the locations you marked in step 12, drilling down through

the 1/16" ply wing bolt plate and through the 1/4" ply hold-

down blocks in the fuselage. Try to drill straight in, perpen-

dicular to the 1/16" ply bolt plate. IMPORTANT!: Do not

allow the wing to move while drilling!

D 14. Remove the wing and re-drill the holes in the wing

only to 1/4".

D 18. Glue the two 1/4" x l -3/4" x 2-1/2" balsa center nose

fillers to the inside edges of the W-2 ribs. Then sand the edges

of these fillers to blend with the LE and LE sheeting.

D 19. Trial fit the wing on the fuselage, and sand the center

nose fillers to mate with the front of the 1/8" ply cabin sides.

Provide at least 1/16" clearance on both sides, between the

wing and fuse, to allow for the thickness of the covering

material and windshield.

U 15. Use a 1/4-20 tap and a tap wrench to cut threads in

the ply hold-down blocks in the fuselage.

D 16. Harden the threads in the hold-down block with thin

CA glue, then re-tap the threads after the glue is completely

dry.

24

MOUNT STABILIZER AND FIN

D 1. Lightly sand the stab saddle area smooth with a

T-bar or sanding block.

D 2. Accurately measure the trailing edge of the stabi-

lizer and mark the center point.

D 3. Temporarily mount the wing in the saddle (for refer-

ence).

D 4. Lay the stab in position on the stab saddle with the

center point lined up with the tail end of the fuselage.

Carefully check the stab alignment by standing directly