Great Planes Extra 300S 1.20 ARF Patty Wagstaff - GPMA1305 User Manual

Page 16

❏

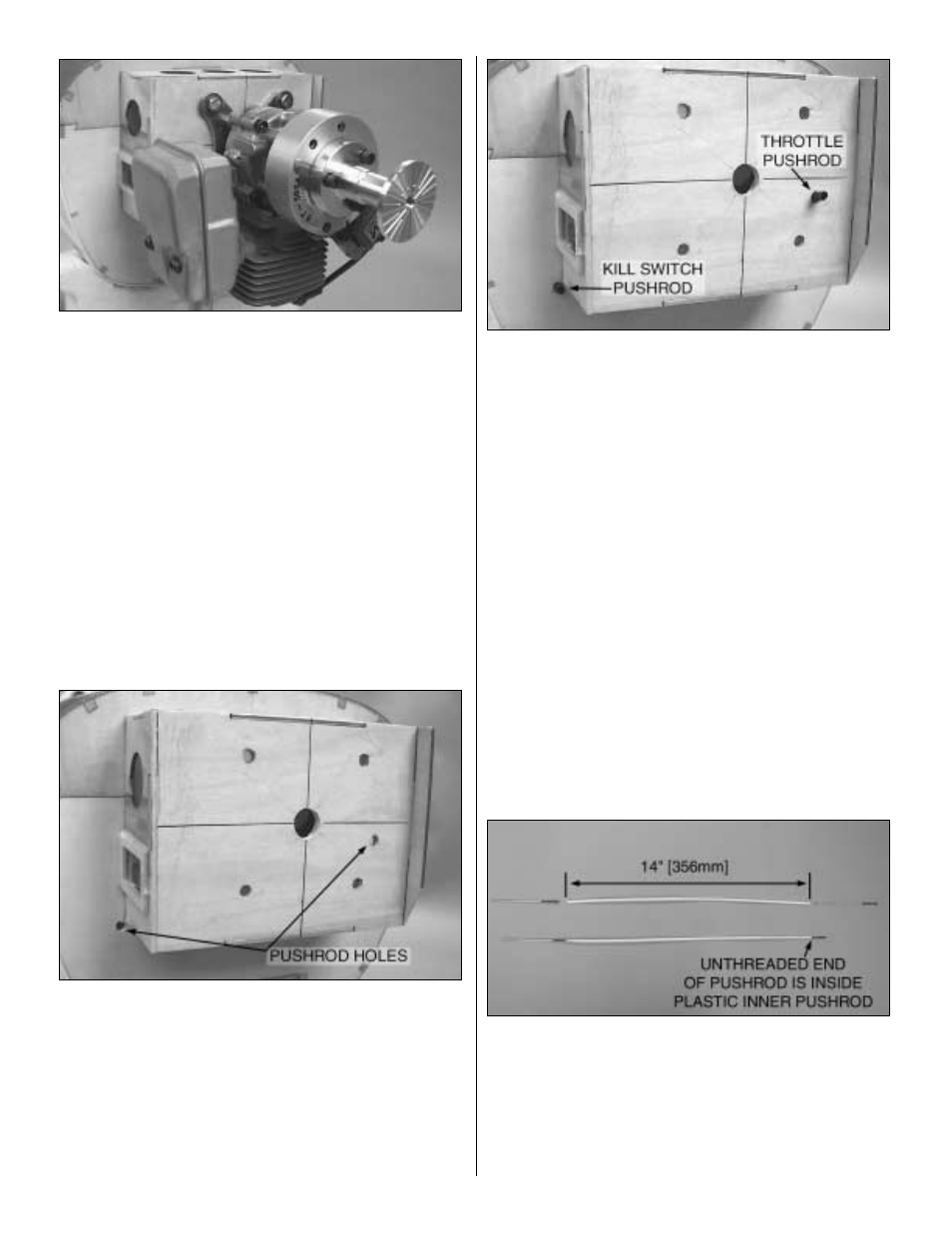

4. Install the engine in place with the hardware recommended

by the manufacturer. For the Fuji BT-50SA you should use

1/4-20 x 1" [25mm] bolts with 1/4-20 blind nuts and 1/4"

[6.4mm] flat washers. Note: Depending on the gas engine

you use, you may need to trim the firewall. For the Fuji

BT-50SA the sides of the firewall needed to be trimmed for

the muffler and for the carburetor’s fuel line.

Warning: All R/C equipment (receiver, batteries, servos and

switches) must be kept at least 12" [305mm] away from a

running gas engine. For this reason, the throttle servo and

the engine kill servo must be installed inside the fuselage. A

manual kill switch should also be installed.

❏

5. Mark the location of the throttle pushrod and of the kill

switch pushrod on the firewall. Remove the engine from the

firewall. Drill two 3/16" [4.8mm] holes through the firewall as

shown. Use a long drill bit to drill through the fuselage

formers. Make sure that you make the holes so that the

pushrods clear the wing tube and that they do not block the

wing mounting screws. Also, make sure you leave enough

space for the fuel tank. Note: The position of your throttle

pushrod and kill switch pushrod will vary depending on the

gas engine you use.

❏

6. Cut a 36" [914mm] plastic outer pushrod (not included)

so that you have one 19" [482mm] and one 17" [432mm]

long pieces. Roughen the ends of the outer pushrods and

use thin CA to glue them in place as shown in the above

image. Leave about 1/4" [6.4mm] of the engine kill pushrod

protruding, but cut the throttle pushrod flush with the

firewall. Note: If the throttle configuration on your Fuji

BT-50SA does not match the one you see in the previous

image, you may have to make changes to the throttle

pushrod location.

❏

7. To make the throttle pushrod you will need a 14"

[356mm] plastic inner pushrod, two 6" [152mm] threaded

one end pushrods a clevis, a clevis retainer and quick

connector. Thread a 6" [152mm] pushrod into each end of

the plastic inner pushrod as shown in the above image. Note

that the threaded pushrods are inserted in different

directions on each end. Make two of these pushrods, one for

the throttle and one for the kill switch.

16