Balance the model laterally, Preflight identify your model, Charge the batteries – Great Planes Cirrus SR22 Turbo ARF - GPMA1166 User Manual

Page 19: Balance propellers, Range check

19

to minimize or eliminate any additional ballast required. If

additional weight is required, nose weight may be easily

added by using a “spinner weight” (GPMQ4645 for the 1 oz.

[28g] weight, or GPMQ4646 for the 2 oz. [57g] weight). If

spinner weight is not practical or is not enough, use Great

Planes (GPMQ4485) “stick-on” lead. A good place to add

stick-on nose weight is to the fi rewall (don’t attach weight

to the cowl—it is not intended to support weight). Begin by

placing incrementally increasing amounts of weight on the

bottom of the fuse over the fi rewall until the model balances.

Once you have determined the amount of weight required, it

can be permanently attached. If required, tail weight may be

added by cutting open the bottom of the fuse and gluing it

permanently inside.

Note: Do not rely upon the adhesive on the back of the

lead weight to permanently hold it in place. Over time, the

adhesive may fail and cause the weight to fall off. Use #2

sheet metal screws, RTV silicone or epoxy to permanently

hold the weight in place.

❏

4. IMPORTANT: If you found it necessary to add any

weight, recheck the C.G. after the weight has been installed.

Balance the Model Laterally

❏

1. With the wing level, have an assistant help you lift the

model by the motor propeller shaft and the bottom of the

fuse under the TE of the fi n. Do this several times.

❏

2. If one wing always drops when you lift the model, it

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been

laterally balanced will track better in loops and other

maneuvers.

PREFLIGHT

Identify Your Model

No matter if you fl y at an AMA sanctioned R/C club site or if

you fl y somewhere on your own, you should always have your

name, address, telephone number and AMA number on or

inside your model. It is required at all AMA R/C club fl ying sites

and AMA sanctioned fl ying events. Fill out the identifi cation

tag on page 21 and place it on or inside your model.

Charge the Batteries

Follow the battery charging instructions that came with your

radio control system to charge the batteries. You should

always charge your transmitter battery the night before you

go fl ying, and at other times as recommended by the radio

manufacturer.

CAUTION: Unless the instructions that came with your

radio system state differently, the initial charge on new

transmitter batteries should be done for 15 hours using

the slow-charger that came with the radio system.

This will “condition” the batteries so that the next charge

may be done using the fast-charger of your choice. If the

initial charge is done with a fast-charger the batteries may

not reach their full capacity and you may be fl ying with

batteries that are only partially charged.

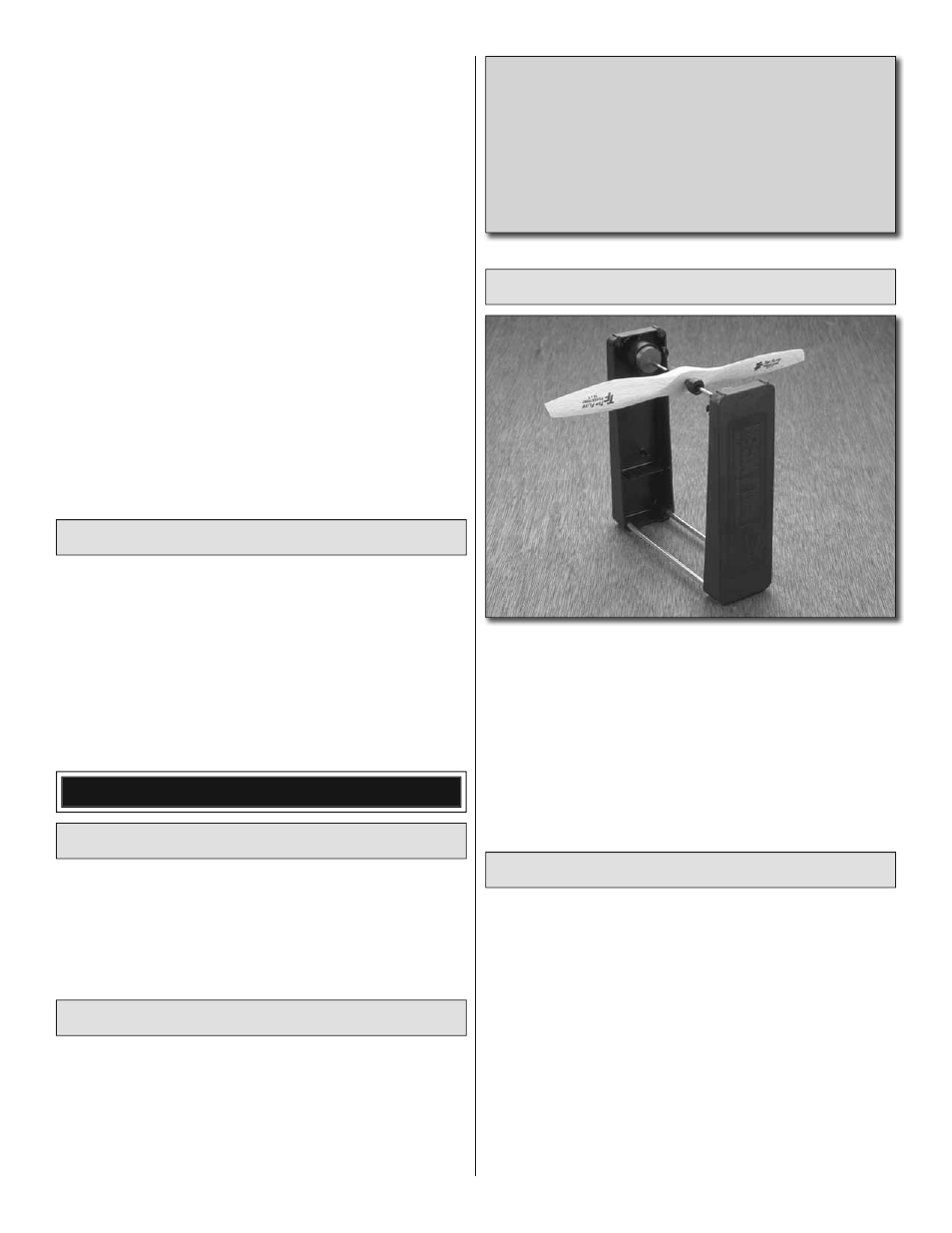

Balance Propellers

Carefully balance your propeller and spare propellers

before you fl y. An unbalanced prop can be the single most

signifi cant cause of vibration that can damage your model.

Not only will motor mounting screws loosen, possibly with

disastrous effect, but vibration may also damage your radio

receiver and battery.

We use a Top Flite Precision Magnetic Prop Balancer

(TOPQ5700) in the workshop and keep a Great Planes

Fingertip Prop Balancer (GPMQ5000) in our fl ight box.

Range Check

Ground check the operational range of your radio before the

fi rst fl ight of the day. With the transmitter antenna collapsed

and the receiver and transmitter on, you should be able to

walk at least 100 feet away from the model and still have

control (follow the instructions that came with your radio if

you are using a 2.4GHz system). Have an assistant stand by

your model and, while you work the controls, tell you what the

control surfaces are doing. Repeat this test with the motor

running at various speeds with an assistant holding the

model, using hand signals to show you what is happening. If

the control surfaces do not respond correctly, do not fl y! Find

and correct the problem fi rst. Look for loose servo connections

or broken wires, corroded wires on old servo connectors,

poor solder joints in your battery pack or a defective cell, or a

damaged receiver crystal from a previous crash.