Great Planes Ultra Sport 60 Kit - GPMA0420 Pages 28-48 User Manual

Great Planes Air equipment

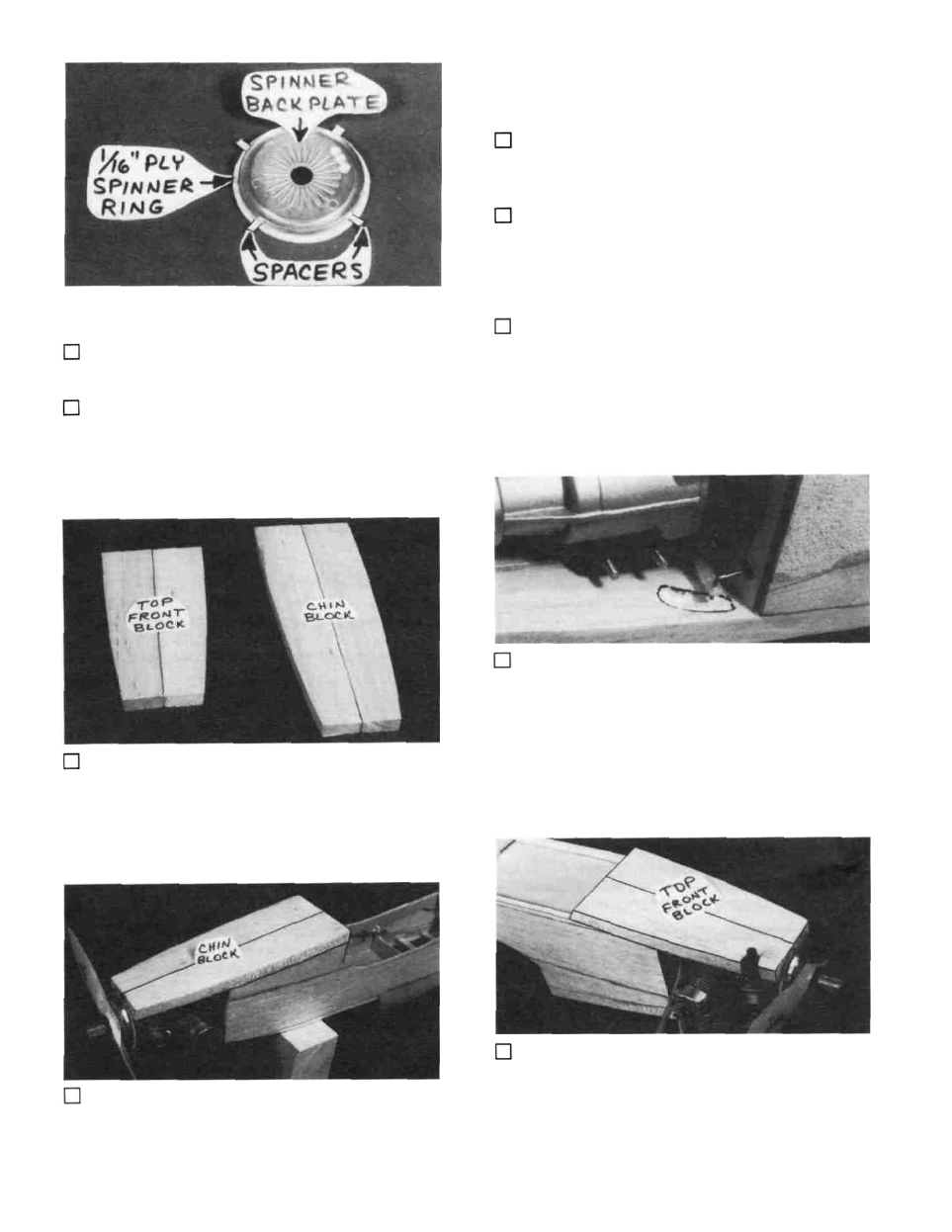

backplate to allow for engine movement. (A space of

approximately 1/8" is probably sufficient).

ring. By trial and error, sand a little at a time off the front of

the chin block until it mates at the proper angle with the back

of the spinner ring.

10. Glue the chin block to the bottom of the fuse and the

spinner ring. You may want to use 5-minute epoxy for this

step to allow some time for careful positioning.

11. Cut off and sand the aft end of the chin block flush

with the aft edge of F-2A.

NOTE: If you are building a taildragger, disregard steps

12 and 13.

12. Turn the fuselage right side up and use a long 5/32"

over the spinner ring, and tack glue it to the 1/32" ply spacers.

6. Now center your2-3/4" diameter spinner backplate

7. Slide the spinner ring / spinner backplate assembly

drill bit (or a sharpened piece of 5/32" O.D. brass tube) to drill

a hole in the chin block for the nosegear wire. Insert the drill

through the holes in the engine mount and drill down through

the chin block.

onto the driveshaft and temporarily hold in place with the

prop and prop nut

13. Temporarily install the nose gear, steering arm and

nosegear pushrod wire. Notice that the pushrod wire will bind

against the chin block in a right turn. Carve out a clearance

slot for the nosegear pushrod in the chin block. Now remove

the nosegear parts.

8. Glue together the two halves of the 5/8" balsa chin

block and the 1/2" balsa top front block. Sand the glue joints

smooth with your T-bar. Fuelproof one side of the chin

block.

9. With the fuselage upside down, lay the chin block in

place on the fuse bottom (fuclproofed side toward inside of

fuse). Note how the front of the chin block meets the spinner

14. Lay the top front block in place on top of the

fuselage. Using the same procedure as you used for the chin

block, sand off the front of the top front block to mate with the

spinner ring. Depending on your engine, you may also have

to carve a groove for the needle valve. In addition, check if

your engine mount touches the top front block, and provide

28