Great Planes Ultimate Biplane 40 Kit - GPMA0240 User Manual

Page 36

D 14. After the filler cures, sand it flush with the plastic.

Wet sand the entire wheel pant with 400-grit sandpaper in

preparation for primer.

Note: Don't forget to reinforce the joints with fiberglass

cloth and CA.

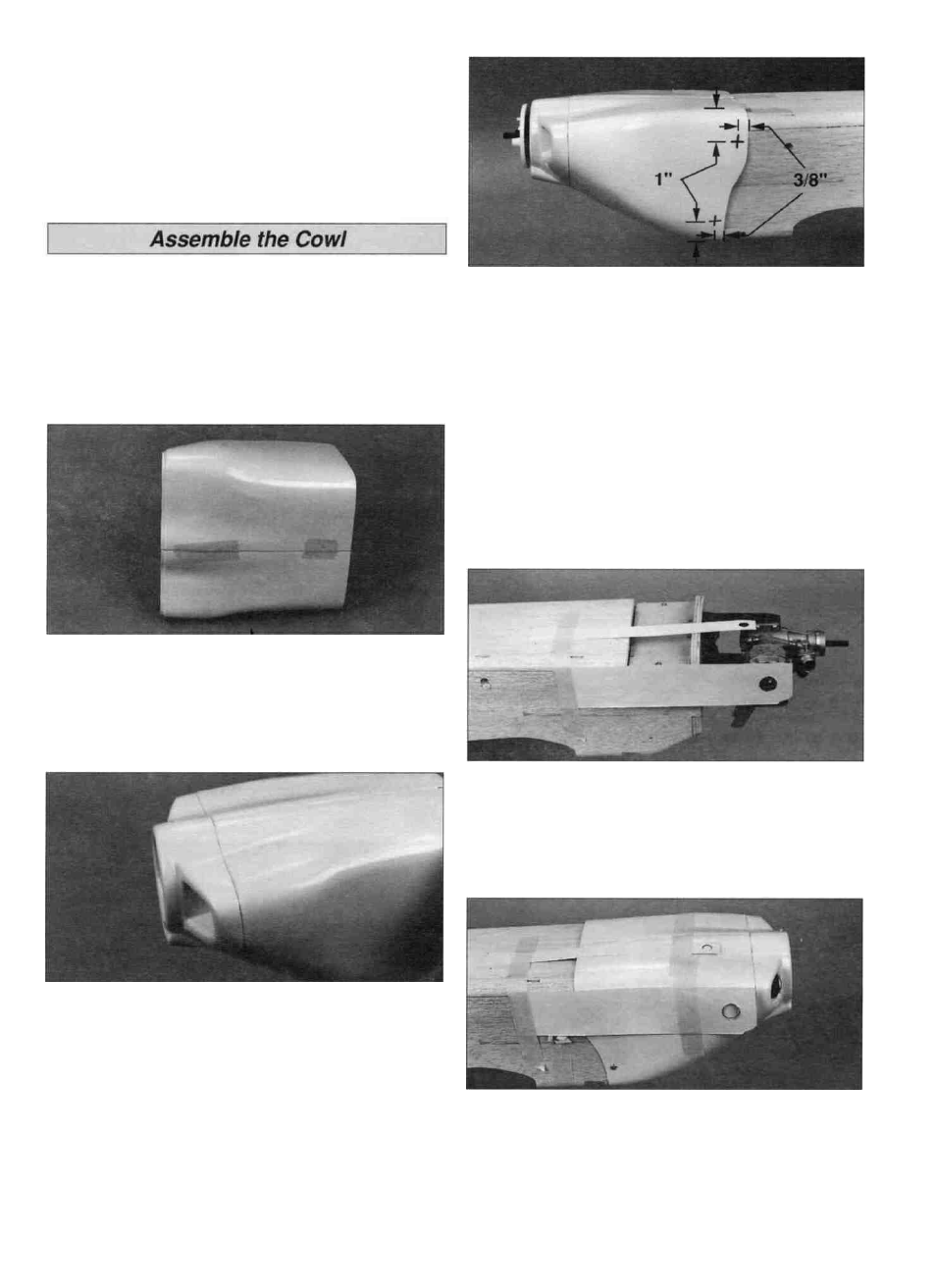

D 1. The cowl is assembled following the same procedure

as the wheel pants. Cut the cowl along the embossed cut

lines. Use your bar sander to true all the edges. For now

the opening in the cowl front only needs to be roughly cut

out. Use coarse sandpaper to roughen the inside of all the

overlapping areas so the glue will adhere better.

D 5. Slide the cowl over the engine and fuselage. Reinstall

the spinner backplate and center the cowl 1/6" to 3/32"

behind the spinner backplate. Tape the cowl in position and

place four marks (two on each side of the cowl) 3/8" in from

the back edge and approximately 1" from the top and

bottom of the cowl.

D 2. Tape the left and right side pieces together, then wick a

small amount of thin CA along the seams of the overlapping

joints. After the CA has cured, remove the tape and make

sure you have thoroughly glued the two pieces together by

inspecting the glue joints and adding thin CA if necessary.

D 6. Drill a 3/32" hole through the cowl and fuse at each

mark. Remove the cowl and enlarge the holes in the cowl

only to 1/8". Apply a couple of drops of thin CA to the cowl

mounting holes in the fuse to harden the wood. Attach the

cowl to the fuse with four #4 x 1/2" sheet metal screws.

D 3. Tape the cowl front to the sides. Use thin CA to tack

glue the bottom of the cowl front to the side. Next tack glue

the top of the cowl front to the sides. After the top and

bottom are glued, start gluing the seam along the sides.

D 7. Remove the cowl and use a piece of thin cardboard

or plastic to make templates for the cutouts in the cowl for

the glow plug, needle valve and exhaust. Tape the

templates to the fuselage side to accurately indicate the

position of the glow plug, needle valve and exhaust.

D 4. Use a sharp hobby knife or a Dremel MultiPro® with a

sanding drum to accurately cut the engine opening in the

front of the cowl.

D 8. Remove the engine and install the cowl. Transfer the

glow plug, needle valve and exhaust holes from the

templates onto the cowl.

36